Powder vacuum weighing system solution

Thursday September-11 2025 14:45:20

Powder vacuum weighing system is an automated equipment that combines vacuum conveying with high-precision weighing technology. The system uses a closed design to effectively avoid dust pollution, material volatilization and cross contamination, while improving weighing accuracy and production efficiency. Due to its own advantages, it can be used in many aspects. As a source manufacturer, we have customers in different industries, and we also provide different Powder vacuum weighing system solution for different customers.

Advantages of Powder vacuum weighing system solution

The powder vacuum weighing system solution fundamentally addresses dust pollution and protects operator health. The combination of high-precision sensors and intelligent control systems far exceeds the accuracy of manual batching. The automated process reduces manual intervention, lowers labor intensity, and avoids cross-contamination caused by manual operations. Whether it's flammable and explosive chemical powders, sterile pharmaceutical raw materials, or hygroscopic food additives, the system offers tailored metering solutions through material customization and functional adaptation.

Powder vacuum weighing system process flow

The core of the powder vacuum weighing system is to build a fully enclosed process of "vacuum conveying - precise weighing - automatic unloading", which completely bids farewell to the dust pollution and error problems of traditional manual weighing.

Vacuum feeding link: The negative pressure generator generates a stable negative pressure to suck the powder (such as flour, medicine powder, lithium battery materials, etc.) in the storage bin into the weighing tank through the food grade / explosion-proof pipe.

Precise weighing link: A high-precision strain sensor is installed at the bottom of the weighing tank to transmit the weight data to the PLC control system in real time. When the material reaches the preset weight, the system automatically closes the vacuum valve and stops loading to ensure that the weighing error of each batch is controlled within 0.2%.

Automatic unloading and linkage: After weighing, the system discharges the powder into downstream equipment (such as mixer, packaging machine) through the pneumatic unloading valve. The unloading process keeps the pipeline closed to avoid secondary pollution.

Powder vacuum weighing system solution

The powder vacuum weighing system solution adopts a fully enclosed automated design, which perfectly solves the problems of dust pollution, volatilization loss, cross contamination and other problems in the powder material metering process. It is suitable for industries with strict requirements on hygiene and precision, such as pharmaceutical, chemical, and food.

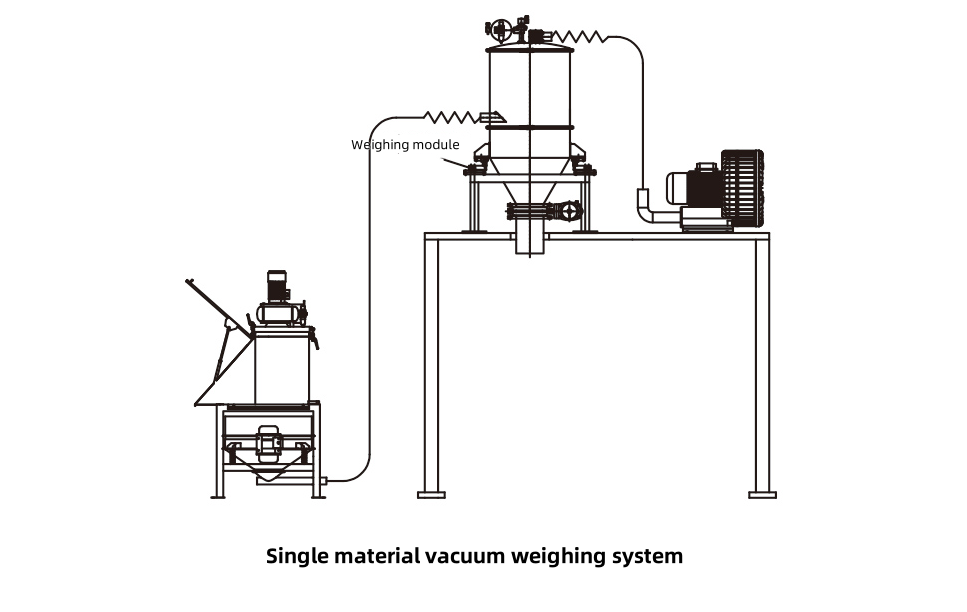

Single material vacuum weighing system: For single powder materials, such as flour and medicinal powder, an integrated design of "vacuum loading + static weighing" is adopted. The material is sucked from the storage bin into the closed weighing tank through a negative pressure pipeline. A high-precision strain sensor is installed in the tank to feed back the weight data to the PLC control system in real time.

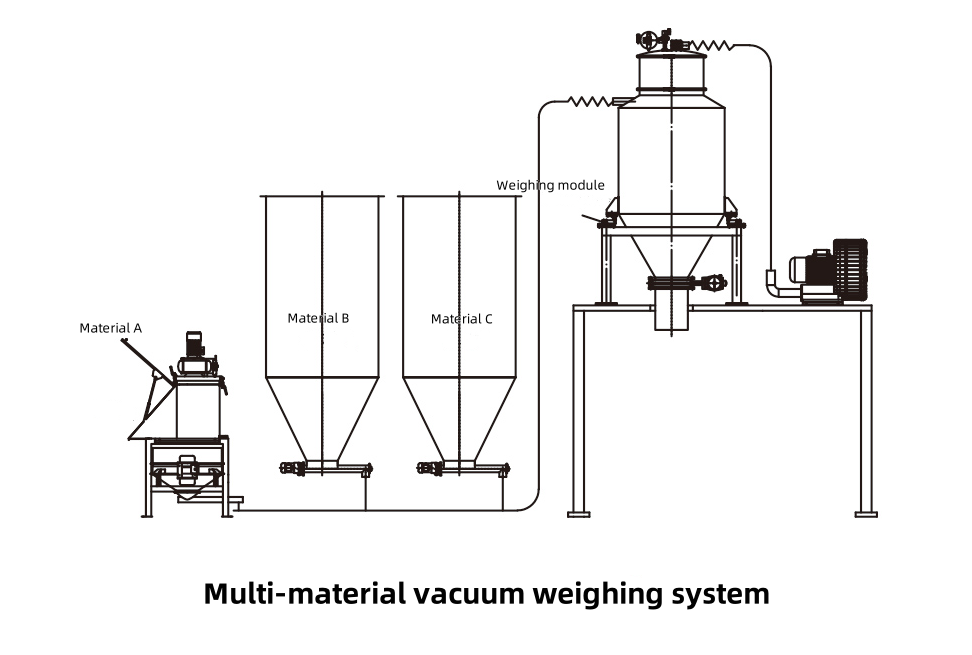

Mixed material vacuum weighing system: Built for multi-component formula production scenarios, integrated with a multi-channel vacuum loading module). Each channel is equipped with an independent weighing unit and an anti-cross-material valve to complete material suction, weighing and verification in sequence according to the preset formula ratio.

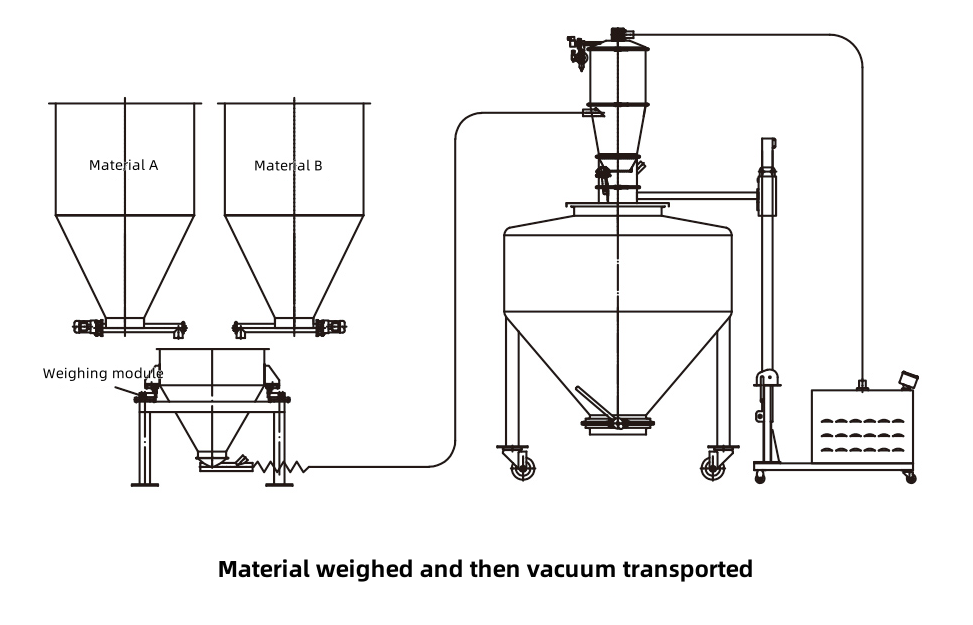

Vacuum conveying of weighed materials: Connect the weighing link with the downstream process, and adopt the "negative pressure difference" conveying technology. The weighed powder is transported in a closed manner through a smooth inner wall pipeline driven by a variable frequency vacuum pump. The pipeline elbow adopts a large curvature design to reduce residue.

Powder vacuum weighing system customer case

We have selected multiple industry application cases to demonstrate from multiple angles how the Powder Vacuum Weighing System Solution can solve pain points such as dust pollution and inaccurate weighing, providing you with references for intelligent solutions.

Lithium battery material industry case: In order to achieve high-precision weighing of powders such as lithium carbonate and graphite, new energy companies use explosion-proof vacuum weighing systems, inert gas protection and PLC automatic control to achieve multi-component precise proportioning. The final production efficiency is increased by 30%, and dust pollution is reduced by 95%, meeting the strict process requirements of lithium battery materials.

Pharmaceutical industry case: In response to the needs of aseptic weighing and cross-contamination prevention, pharmaceutical factories choose 316L stainless steel material systems, which meet the standards and are equipped with online cleaning functions. Weighing accuracy of ±0.1% is achieved, greatly improving the compliance of drug production.

Food additive industry case: Food companies use low-oxygen vacuum conveying and dehumidification systems to automatically weigh vitamin powder to prevent moisture absorption and contamination. Weighing efficiency is increased by 50%, product quality is more stable, and customer satisfaction is significantly improved.

Powder vacuum weighing system manufacturer

We specialize in the research, development, and manufacturing of vacuum weighing systems. Our core products include single-ingredient and mixed-material vacuum weighing equipment and explosion-proof weighing systems. Utilizing 304/316L stainless steel, our systems are suitable for a wide range of applications. Customizable features such as anti-oxidation and dehumidification are available, meeting multiple certification requirements and providing full-lifecycle support. We have provided powder vacuum weighing system solution to over 500 companies and have earned recognition for our reliable technology and service.

Powder vacuum weighing systems are becoming the core equipment of modern industrial production with their advantages of high precision, dust-free, safe and reliable. Whether it is new energy, pharmaceutical or food industry, customized solutions can help companies optimize production processes, improve product quality and reduce operating costs.