Dust-Free Vacuum Loading Machine

Dust-Free Vacuum Loading Machine is a closed-loop conveying device based on the vacuum principle, specifically designed to address dust pollution during the transfer of powdered and granular materials.

Material: 304, 316 stainless steel

Voltage: 220V/380V / Customizable

Capacity:10 kg - 10 tons/hour

Length: Customizable, 1-100 meters

Main Components: PLC, motor, bearings

Applicable Materials: Milk powder, powdered sugar, flour, coffee powder, cocoa powder, grain granules, candy granules, chopped nuts, metal and/or plastic microspheres

What is a Dust-Free Vacuum Loading Machine?

Dust-Free Vacuum Loading Machine uses a vacuum pump to create negative pressure within a closed system, forcing powders, granules, and other materials into a dedicated pipeline under the pressure differential. Material-contacting components are primarily made of stainless steel and mirror-polished. The suction port and discharge valve are connected via seamless welding or food-grade seals. These features prevent residue, corrosion, and diffusion, ensuring product quality while protecting personnel health and minimizing safety risks. They are key equipment for achieving both rapid production and cleanliness standards.

What are the advantages of a Dust-Free Vacuum Loading Machine?

The Dust-Free Vacuum Loading Machine's core advantages are its highly effective use of negative pressure suction for fully enclosed conveying, eliminating dust leakage and material contamination. Made of 304/316L stainless steel, it is suitable for a wide range of industries.

Improves product quality: Dust-free conveying reduces material contamination and waste, and can reduce product defect rates by 15%-30%.

Ensure operational safety: Prevent operators from inhaling dust. For flammable and explosive materials, explosion-proof design is available to further enhance safety.

Improve production efficiency: Automated conveying replaces manual feeding, achieving a conveying efficiency of 0.1-5 tons/hour and enabling 24-hour continuous operation, significantly reducing labor costs.

Anti-clogging and dust cleaning design: Select models are equipped with an automatic backflush system to regularly remove dust adhering to the filter surface, preventing filter clogging and affecting negative pressure stability.

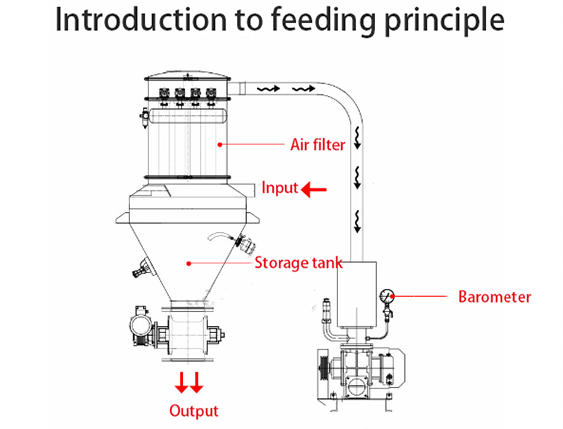

Working Principle of the Dust-Free Vacuum Loading Machine

The dust-free nature of the Dust-Free Vacuum Loading Machine stems from its triple guarantee of "negative pressure adsorption + gas-material separation + airtight sealing." A vacuum pump extracts air from the system, creating a stable negative pressure of -0.02 to -0.06 MPa. The pressure differential draws the material into a sealed pipe, preventing dust from flying. High-precision filters, such as built-in HEPA filters and PTFE-coated filter elements, intercept over 99.99% of fine dust, separating the gas and material for clean exhaust, eliminating dust from exhaust. From the intake port, conveying pipe, and discharge valve, the entire process utilizes seamless welding or food-grade seals, eliminating gaps and completely blocking contact between the material and the outside air, preventing dust from escaping and contaminants from entering.

Dust-Free Vacuum Loading Machine Model Specifications

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Dust-Free Vacuum Loading Machine Main Structure

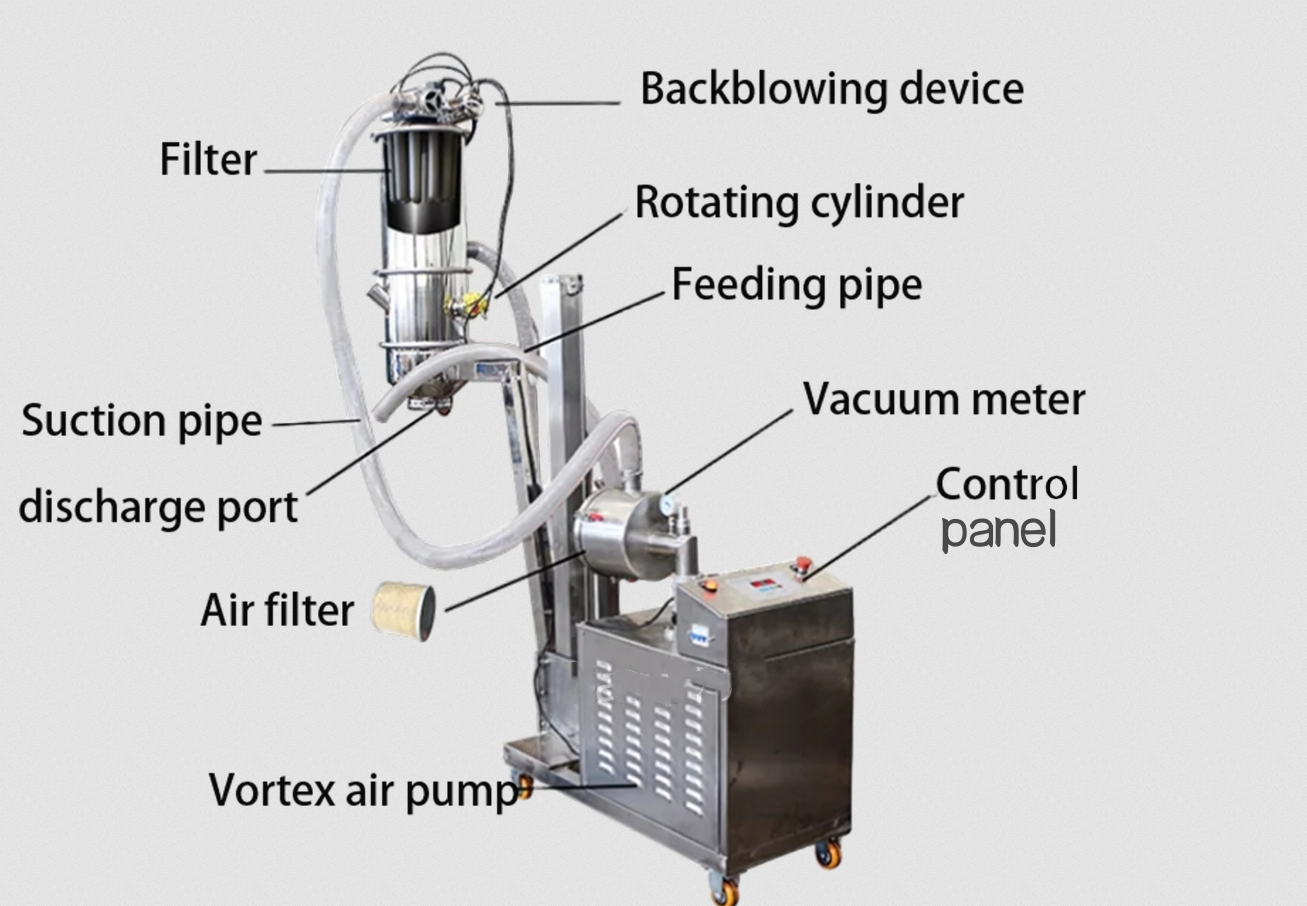

The core components of the Dust-Free Vacuum Loading Machine are designed around four key functions: negative pressure generation - material conveying - air-material separation - and sealed unloading. These components work together to ensure dust-free and efficient conveying.

The negative pressure generator: This is the power source of the machine, typically a vacuum pump or generator, which steadily extracts air from the system, providing power for material suction and conveying.

The suction assembly: This is responsible for collecting material at the inlet and includes the suction port and suction gun. Some food/pharmaceutical-grade equipment utilizes 316L stainless steel with a polished interior to prevent material residue.

The conveying pipe: This connects the suction assembly to the separation device. It is typically constructed of 304/316L stainless steel and connected using seamless welding or quick-connect fittings. Its interior is smooth to minimize material retention.

The air-material separation system: This is the core component for achieving dust-free operation and consists of a separation hopper and a high-precision filter. The separation hopper temporarily stores materials and filters fine dust from the airflow. Clean air is then discharged through a filter, eliminating dust from exhaust.

The discharge device :is responsible for dust-free discharge of the separated materials. Commonly used devices include pneumatic butterfly valves, star-shaped discharge valves, or double-flap valves. Food-grade/pharmaceutical-grade seals ensure a fully sealed discharge process, preventing air from entering or material from spilling.

What types of materials are suitable for conveying with a Dust-Free Vacuum Loading Machine?

With its fully enclosed and high-precision filtration capabilities, the Dust-Free Vacuum Loading Machine is suitable for conveying materials in a variety of industries and forms, primarily covering powders, granules, and microspheres.

Powdered materials: These include milk powder, powdered sugar, flour, coffee powder, and cocoa powder in the food industry; raw material powders and pharmaceutical excipients in the pharmaceutical industry; lithium battery positive and negative electrode powders and ultrafine powders for semiconductor packaging in the electronics industry; and pigment powders, coating powders, and flame retardant powders in the fine chemical industry. This machine is particularly suitable for ultrafine powders prone to dust generation, preventing dust dispersion during conveying.

Granular materials: These include grain granules, candy granules, and chopped nuts in the food industry; capsules, granules, and Chinese herbal medicine slices in the pharmaceutical industry; resin granules, fertilizer granules, and plastic masterbatches in the chemical industry; and laundry detergent granules and fragrance granules in the daily chemical industry. Suitable particle sizes typically range from 0.1mm to 10mm, preventing particle breakage and cross-contamination.

Microspherical/irregular small materials: These include chocolate chips and small baking ingredients in the food industry; micropellets in the pharmaceutical industry; and metal/plastic microspheres in the 3D printing industry. The machine's smooth interior and precise negative pressure control ensure complete conveying of these materials, without residue or blockage.

Dust-Free Vacuum Loading Machine Selection Recommendations

Dust-Free Vacuum Loading Machine selection should focus on three core dimensions: material characteristics, production requirements, and application compliance. This approach avoids parameter mismatches that can lead to low conveying efficiency, ineffective dust control, or equipment loss.

Prioritize matching core material characteristics: Determine basic parameters based on material form, particle size, and specific gravity. For powdered materials, a separation system with a HEPA or PTFE filter element should be selected to prevent dust penetration. For granular materials, consider stainless steel piping with smooth interior walls and a low-speed discharge valve to prevent particle breakage. For high-specific-gravity materials, upgrade to a high-power vacuum pump to ensure sufficient negative pressure to propel the material.

Accurately calculate production conveying requirements: Determine equipment specifications based on hourly conveying capacity and conveying distance. For hourly conveying capacities of 1-5 tons, a small single-unit model is recommended, while for 5-20 tons, a medium-sized dual-pump model is recommended. For horizontal conveying distances exceeding 10 meters or vertical heights exceeding 5 meters, additional negative pressure loss must be calculated and a vacuum pump with a pressure range exceeding the upper limit should be selected.

Strictly comply with application-specific compliance requirements: 316L stainless steel is preferred for the food/pharmaceutical industry, seals must be FDA-certified, and the equipment must support CIP (Cleaning in Place) cleaning. Explosion-proof vacuum pumps and anti-static piping are essential for chemical and explosion-proof applications. Oil-free vacuum pumps are recommended for the electronics industry.

Focus on the compatibility of additional functions: If continuous operation is required, a model with dual-hopper alternating unloading is recommended. If material residue is prone to buildup, a separation system with backflush cleaning and internal polishing is preferred.

Customized Dust-Free Vacuum Loading Machine Solutions

To address the material handling challenges faced by industries like food, pharmaceutical, and electronics, we offer customized solutions for Dust-Free Vacuum Loading Machines. Based on material characteristics, we match 304/316L stainless steel materials with explosion-proof and anti-static features to address dust pollution and regulatory compliance challenges.

Dust-free conveying of infant formula powder: This system requires conveying ultrafine powder with a particle size of 2-5μm. The core requirement is 100% elimination of dust contamination. The customized solution utilizes 316L stainless steel for material-contacting components, an oil-free vortex vacuum pump to prevent oil contamination, an upgraded 14-stage filter with automatic pulse backflush cleaning, and the addition of a CIP cleaning port and temperature sensor. The control system is linked to the production line PLC.

High-potency API conveying: This system requires conveying highly potent APIs, requiring "zero human-material contact" and meeting GMP aseptic requirements. The customized solution utilizes a fully isolated structure with material-contacting components constructed of 316L stainless steel and PTFE lining, equipped with an explosion-proof vacuum pump and a double-sealed discharge valve. The gas-material separation module is equipped with a filter and activated carbon adsorption layer. The control system integrates permission management and operation traceability, and outputs verification documents.

Lithium Battery Cathode Material Conveying: This conveying system is designed for lithium battery ternary cathode materials, which are prone to static electricity and susceptible to metallic impurities. It requires both dust-free and anti-static operation, a conveying capacity of 5 tons/hour, an 8m vertical conveying height, and zero risk of metal debris falling from the equipment. This customized solution utilizes electrolytically polished 304 stainless steel material-contacting components, an oil-free screw vacuum pump, an air-material separation module equipped with an anti-static PTFE-coated filter element, and an ionizing air wand. Quick-connect connectors are used in the conveying pipeline to eliminate welding residue, and a control system monitors static voltage and conveying pressure in real time.

Dust-Free Vacuum Loading Machine Manufacturer

With over a decade of experience in the powder conveying industry, we are a high-tech enterprise integrating R&D, production, and sales. Focusing on "dust-free and intelligent" technologies, the company independently develops its own vacuum loader. Made of finely polished 304/316L stainless steel, the Dust-Free Vacuum Loading Machine features a fully enclosed structure and a high-efficiency filtration system to achieve zero dust leakage and eliminate material contamination. Strict quality control is maintained throughout the entire process, from R&D and design to production and assembly, allowing for customized services tailored to suit different materials and production capacities.

The Dust-Free Vacuum Loading Machine is more than just a tool for material transportation; it serves as the foundation of intelligent manufacturing in the industrial age. Through technological innovation, it addresses the pain points of traditional industries and promotes rapid, safe, and sustainable transformation in sectors such as chemical, pharmaceutical, and food.