Ultrasonic Sieve

On the basis of ordinary sieve machine, ultrasonic sieving device is added, the ultrasonic vibration frequency can reach 36,000 times/second, which is suitable for sieving 0-625 mesh fine powder, and the output can be increased by 0.5-10 times.

Price: $300.00-$4,500.00/Set

Screen specifications: 50-625 mesh

Production: 1~5 tons/hour

Number of layers: 1~5 layers

Screening materials: starch, iron powder, aluminum powder, ceramic powder, shell, stone powder, powder coating, alloy powder, electromagnetic powder, etc.

What is Ultrasonic Sieve?

Ultrasonic Sieve is a superimposed ultrasonic system on the basis of a vibrating screen. It applies ultrasonic frequency (38-40kHz) to the screen. It can be used to screen materials of 40-635 mesh (400-635 mesh is dominated by high precision). It is especially good at ultrafine powders below 100μm, and there will be no clogging. Compared with ordinary vibrating screens, its screening accuracy is improved by 1-70%, the screen surface pass rate can be increased by 50%-400%, and the output can be increased by 0.5-10 times. It effectively solves the problems of screening ultrafine powder materials such as strong adsorption, static electricity, strong viscosity, and high density. It is the preferred equipment for screening fine powders such as flour, graphite powder, rubber powder, quartz sand powder, metal powder, powder coating, and fluorescent powder.

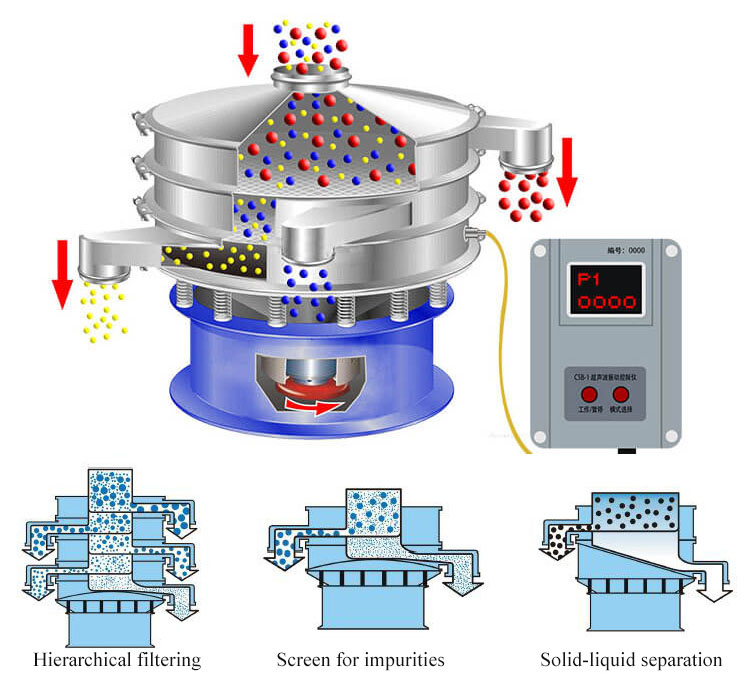

What types of Ultrasonic Sieve are there?

Ultrasonic Sieve can be divided into built-in and external types according to the installation position of the transducer. The materials include carbon steel and stainless steel. The number of screen layers is divided into 1 layer, 2 layers, 3 layers, 4 layers, and 5 layers. It can simultaneously sort out 2-6 materials of different particle size specifications.

Built-in Ultrasonic Sieve: The ultrasonic transducer is installed at the bottom of the screen. When screening some corrosive materials, it will seriously damage the use of the transducer and affect the output frequency. It is impossible to screen corrosive materials. However, it can be used in the food industry to avoid cross contamination.

External Ultrasonic Sieve: The ultrasonic transducer is installed outside the screen frame and will not come into contact with the material. It can avoid damage to the transducer when screening corrosive materials, and can increase the service life and output of the screen.

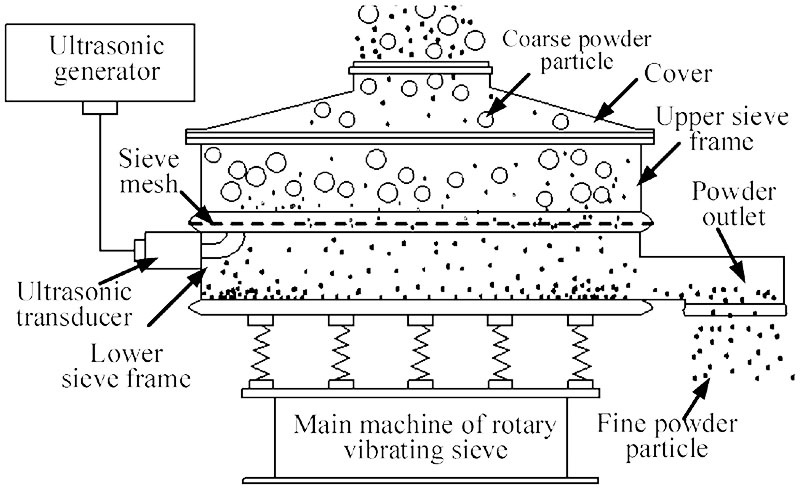

What is the working principle of Ultrasonic Sieve?

The high-frequency electricity generated by the Ultrasonic Sieve power supply is converted into a longitudinal oscillation wave formed by a high-frequency sine through a transducer. These oscillation waves are transmitted to the resonator to make the resonator resonate, and then the resonator transmits the vibration evenly to the screen surface. While the material on the screen is vibrating at a low frequency three-dimensional vibration, it is superimposed with ultrasonic vibration, which can not only prevent the mesh from being blocked, but also improve the screening output and accuracy.

What are the advantages of Ultrasonic Sieve?

The Ultrasonic Sieve is equipped with an ultrasonic screening system, which drives the transducer through a CNC power supply and transmits high-frequency vibration to the screen at 360,000 times/minute, completely solving the blockage problem and achieving high-precision screening: it can process 25µm powder and 10µm liquid, and keep the material properties unchanged. Compared with ordinary vibrating screens, the screening accuracy is improved by 1-70%, the output is increased by 0.5-10 times, and no rubber ball is required to clean the net to avoid rubber wear and pollution. It supports single-layer or multi-layer configurations, and one intelligent generator can drive three transducers synchronously, which is efficient and flexible. It uses a fully enclosed aviation-grade integrated circuit board, which can run stably and continuously for 12-24 hours without cooling. The screen is fixed by bonding, which is pollution-free, has no dead angle, is evenly stressed, and is easy to replace; the separated structure design is matched with a resonance ring to extend the life of the screen and improve the screening effect.

Ultrasonic Sieve Parameters

| Model |

Effective diameter mm |

Screening area m2 |

Screen specification mesh |

Number of layers layer |

Input power V/HZ |

Ultrasonic Model |

Transducer Position |

Frequency Frequency KHz |

Ultrasonic Gear |

Power Kw |

| DHC-200 | 200 | 0.03 | 10-1200 | 1-7 | 220/50 | ZTC-7 | External | 38KHz |

Continuous 1-9 gears Pulse 2 gears |

0.18 |

| DHC-400 | 340 | 0.09 | 60-635 | 1-3 |

Vibrating screen 380/50 Ultrasonic 220/50 |

Internal/External | 0.25 | |||

| DHC-600 | 540 | 0.23 | 0.55 | |||||||

| DHC-800 | 730 | 0.42 | 0.75 | |||||||

| DHC-1000 | 900 | 0.64 | 1.1 | |||||||

| DHC-1200 | 1100 | 0.95 | 1.5 | |||||||

| DHC-1500 | 1400 | 1.54 | 2.2 | |||||||

| DHC-1800 | 1700 | 2.27 | 3.0 |

What is the difference between Ultrasonic Sieve and ordinary vibrating screen?

Ultrasonic Sieve is equipped with an ultrasonic screening system, with a vibration frequency of up to 36,000 times per second. It is suitable for separating powders with 80-600 mesh screens, especially for materials that are difficult to screen, and the output can be increased by 0.5-10 times.

| Comparison items | Ultrasonic Sieve | Ordinary vibrating screen |

| Applicable mesh range | 40-635 mesh (optimal 400-600 mesh) | Usually no more than 300 mesh |

| Blocking problem | With self-cleaning function, no mesh clogging | Easy to clog the mesh, need frequent cleaning |

| Screening accuracy | Increase by 10%-70% | Basic level |

| Processing capacity | Increase by 0.5-10 times | Standard level |

| Static/agglomerated materials | Effectively solve the problems of high static electricity and easy agglomeration | Cannot be effectively handled |

| Automation level | Intelligent control, adjustable parameters | Usually mechanical control |

| Model (mm) | Ordinary screening machine | Ultrasonic vibration screen | |||

| Test material | Screen | Test results | Mesh | Test results | |

| Φ1000 | Silicon carbide | 500 | Cannot be screened | 500 | 1500KG/H |

| Φ1000 | Tungsten carbide powder | 600 | No fine powder was screened out in 15 minutes | 600 | 30KG/H |

| Φ1000 | Vitamin C powder | 400 | 1KG/H | 100 | 120-150KG/H |

| Φ500 | Pollen | 400 | No fine powder was sieved out in 15 minutes | 400 | 20% fine powder was sieved out in 15 minutes, and finer and more effective classification can be carried out |

| Nickel powder, cobalt powder | 325 | Screen three times to meet the requirements | 400 | Screen once to meet the requirements | |

| Φ450 | NdFeB powder | 300 | 32.2% sieve residue in 30 minutes | 300 | 6.9% sieve residue in 30 minutes |

What are the structural components of Ultrasonic Sieve?

Ultrasonic Sieve is mainly composed of screen frame, ultrasonic grid (including resonance ring), transducer, intelligent generator, CNC power supply and screen. The screen frame adopts a layered design and supports single-layer or multi-layer installation; the ultrasonic grid fixes the screen by bonding to ensure no pollution and uniform force; the transducer converts high-frequency electrical signals into mechanical vibrations; the intelligent generator drives the transducer to achieve high-frequency micro-amplitude oscillation of 360,000 times/minute; the CNC power supply accurately adjusts the parameters. The whole machine adopts a separate structure, does not require a rubber ball to clean the net, has good sealing, and is suitable for the screening needs of materials of different particle sizes.

What are the applications of Ultrasonic Sieve?

Ultrasonic vibration screen can be used for 400 mesh, 500 mesh and 600 mesh screening of lithium battery positive electrode materials, negative electrode graphite powder, silicon carbide, alloy powder, molybdenum powder, stainless steel powder, tungsten powder, nickel powder, cobalt powder, copper powder, powder coating, quartz powder, butamidone powder, malt powder, viravir, coffee powder, electromagnetic powder, negative electrode materials, laser powder, medicinal powder, probiotics and ceramic glaze.

| Material | Screening method | Screen mesh number (mesh/inch) | Output (kg/hour) |

| Flour | Dry type | 16, 20 | 800 |

| Sugar | Dry | 4, 20 | 2000 |

| Chinese medicine | Dry | 80, 100, 150 | 1400 |

| Resin powder | Dry | 40, 60, 80 | 1000 |

| Grinding powder | Dry | 40, 60, 80 | 1200 |

| Pigment powder | Dry type | 40, 60, 240 | 4000 |

| Iron powder | Dry type | 20 | 2500 |

| Copper powder | Dry type | 60, 80, 120 | 2000 |

| Graphite | Dry type | 80 | 1400 |

Sieve For Polystyrene Pellets

Sieve For Polystyrene Pellets Foam Screening Machine

Foam Screening Machine Solid Liquid Separation Equipment

Solid Liquid Separation Equipment