Granule Vacuum Loading Machine

Granule Vacuum Loading Machine automates the conveying of granular materials, utilizing the vacuum principle for airtight and rapid material transfer.

Dimensions (L*W*H): Varies depending on model

Material: 304, 316 stainless steel

Voltage: 220V/380V/415V or custom

Customization: Accepted

Type: Pneumatic/Electric/Continuous/Hand-crank/Mobile

Core Components: Motor, bearings, gears, pump, gearbox, engine

Applications: Suitable for conveying grains, sugar granules, coffee beans, nuts, milk powder pellets, seasoning granules, and other types of granules for various industries

What is a Granule Vacuum Loading Machine?

Granule Vacuum Loading Machine is used to transport various types of granular materials. Using a vacuum pump to generate negative pressure, it precisely delivers materials such as plastic granules, food ingredients, and chemical products through a sealed pipe to a designated workstation, completely resolving the low efficiency, high pollution, and high waste associated with traditional manual feeding. Its modular design allows it to accommodate granules of varying sizes, densities, and fluidities, and supports customization for requirements such as explosion-proof, sterile, and anti-static properties.

What types of Granule Vacuum Loading Machines are there?

Granule vacuum loaders are available in various types, including manual and mobile, based on their structure and function, meeting the diverse needs of industries such as plastics, food, and pharmaceuticals.

Manual Granule Vacuum Loading Machines: Utilizing a manual crank as the core operating aid, they are suitable for small-batch, low-frequency granule transport. Their streamlined design requires no external power source, and the vacuum level and discharge valve are manually adjusted, making them flexible, cost-effective, and easy to maneuver into confined workstations.

Mobile Granule Vacuum Loading Machine: Equipped with universal wheels and a telescopic conveying tube, it features flexible transport and multi-station adaptability. It integrates a vacuum pump and storage hopper, enabling automated intake and discharge cycles via simple PLC control. Its portability significantly enhances its adaptability to production lines.

What are the advantages of the Granule Vacuum Loading Machine?

With its core advantages of being airtight and dust-free, high-speed, energy-efficient, and intelligently controllable, the Granule Vacuum Loading Machine eliminates dust spillage, ensuring a clean and safe production environment, making it an ideal choice for granular material conveying in various industries.

Protecting Granule Integrity: Given the fragile nature of granular materials, the equipment utilizes a low-speed conveying design and a large-diameter, smooth pipe to minimize collisions and abrasion during conveying.

Continuous Conveying: It can achieve a conveying capacity of 1-15 tons per hour and supports 24-hour operation. Conveying distances of up to 50 meters horizontally and 20 meters vertically meet the material supply needs of large-scale production. Dust-free conveying: Fully enclosed pipeline conveying completely eliminates particle spillage and dust flying, improving the workshop environment and reducing the risk of dust inhalation for workers.

Compatible with multiple equipment: It can seamlessly integrate with mixers, granulators, packaging machines, and other equipment. Automation is achieved through a PLC control system, reducing manual labor.

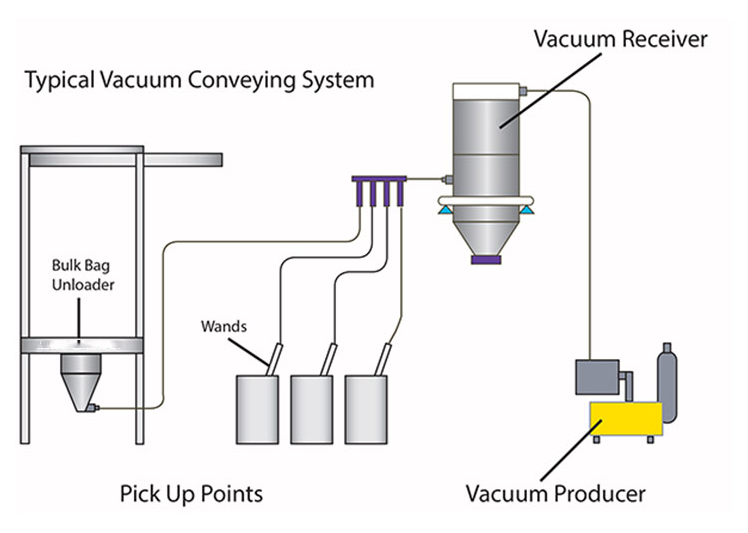

How does the Granule Vacuum Loading Machine work?

The Granule Vacuum Loading Machine utilizes negative pressure adsorption technology. Upon startup, the vacuum pump creates a stable negative pressure between the exhaust pipe and the air in the hopper. This pressure differential smoothly draws the granules from the intake port and conveys them into the hopper. Unlike powder conveying, it utilizes a larger inner diameter and smooth inner wall pipe to prevent particle breakage and clogging. A dedicated air-material separation device ensures particle deposition and purified air discharge, achieving both efficiency and minimizing waste.

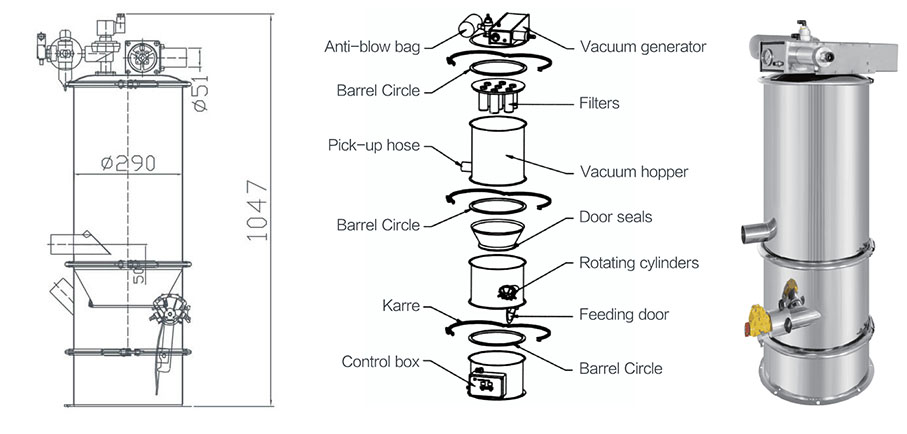

What are the main components of the Granule Vacuum Loading Machine?

The Granule Vacuum Loading Machine utilizes a modular design, primarily consisting of a vacuum pump system and enclosed conveying pipelines. The compact structure ensures durability and ease of maintenance, meeting the automated conveying requirements of various granular materials. Vacuum Generation System: Consists of a vacuum pump and a vacuum buffer tank. This effectively prevents interruptions in particle conveying caused by momentary air pressure fluctuations, ensuring smooth and reliable conveying.

Suction Device: Consists of a suction nozzle adapted for different particle sizes and a wear-resistant, kink-resistant flexible suction tube. The suction nozzle is carefully designed based on particle size to effectively prevent clogging and ensure smooth suction.

Conveying Pipe: Utilizes a large-diameter, smooth-walled material such as stainless steel or wear-resistant plastic. The large-diameter design reduces friction and collisions during conveying, lowering the risk of particle breakage.

Separation Hopper: Contains a dedicated air-material separator, commonly available in baffle or cyclone types. It operates by utilizing the difference between gravity and air velocity to cause particles to settle within the separator, effectively preventing fine particles from escaping with the airflow.

Granule Vacuum Loading Machine Model Specifications

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

What types of particles can the Granule Vacuum Loading Machine convey?

This equipment is designed specifically for granular materials and is suitable for use in industries such as plastics, food, chemicals, and pharmaceuticals. It can handle dry, fluid particles with a particle size of 0.5-10mm. Its special design also allows for efficient, dust-free conveying of slightly sticky or high-density materials.

Plastic granules: These include PP, PE, ABS, PVC, PS, PET, and other plastic raw material granules, widely used in injection molding, extrusion, blow molding, and other plastic product production applications. The equipment can be equipped with an optional anti-static design to prevent static adsorption of particles to pipe walls.

Food-grade granules: These include grains, sugar granules, coffee beans, nuts, milk powder pellets, and seasoning granules, primarily used in food processing, baking, and beverage production. The equipment is constructed of stainless steel and fully complies with food hygiene standards.

Chemical granules: These include fertilizers, catalysts, resin granules, rubber granules, and ion exchange resins, and are used in chemical production, water treatment, and the rubber and plastics industries. To address the corrosive nature of some materials, the equipment can be designed with corrosion-resistant coatings or PP materials. Pharmaceutical granules: These include pills, capsules, granular APIs, and pharmaceutical excipients, primarily used in pharmaceutical and healthcare product production, ensuring dust-free and sterile transportation to prevent cross-contamination.

New energy material granules: These include lithium battery cathode and anode materials, silicon granules, and photovoltaic materials, used in the new energy battery and photovoltaic manufacturing industries. The equipment features an explosion-proof design and an optional nitrogen protection system, effectively handling the conveying of flammable and explosive materials.

Applicable Particle Characteristics

Particle Size Range: Typically 0.5mm to 10mm, with customization available for larger or smaller particles.

Flowability: Suitable for free-flowing or slightly sticky particles. Excessively sticky particles require an auxiliary arch-breaking device.

Density: Suitable for both lightweight and dense particles.

Granule Vacuum Loading Machine Customer Solutions

We offer professional solutions for the diverse granule conveying needs of the plastics, food, and pharmaceutical industries. From anti-static plastic granule conveying to food-grade, pollution-free designs, and pharmaceutical aseptic environment requirements, we offer perfect adaptation and support custom customization, ensuring high-speed, stable, and dust-free automated production.

Plastics product factory: To address the low efficiency of manual feeding of PP granules and the high dust levels in the workshop, we adopted an anti-static vacuum loader equipped with a large-capacity storage silo and integrated PLC control to enable unmanned feeding.

Food processing plant: To ensure contamination-free raw material transportation and meet standards, we customized a stainless steel food-grade vacuum loader with an airflow screening function to remove debris. The equipment fully meets certification requirements, achieving zero-contamination conveying.

Pharmaceutical company: To ensure aseptic transfer of coated pills across workshops, we adopted a vacuum loader equipped with a cleaning system and a low-suction mode to prevent coating damage. Ultimately, this achieves aseptic conveying and eliminates cross-contamination.

Granule Vacuum Loading Machine Selection Guide

Choosing the right granule vacuum loader requires comprehensive consideration of material, conveying capacity, and functional configuration. We'll explain key selection points to help you build a fast and stable automated conveying system.

Select by Material Characteristics: Different granule types require customized designs: Plastic granules require anti-static models to prevent adsorption; food granules use stainless steel to meet hygienic standards; chemical granules use PP coating or 316L stainless steel for corrosion resistance; pharmaceutical granules require a sterile design and low suction to prevent breakage.

Select by Conveying Requirements: Conveying capacity depends on production capacity. For small batches, choose an economical 1-3 t/h model; for large-scale production, choose a high-power 5-10 t/h model. For conveying distances, standard models are suitable for short distances, while enhanced vacuum pumps are required for long distances or vertical conveying. The degree of automation can be customized. Basic models with manual control are suitable for simple production lines, while intelligent models with a PLC and touch screen support quantitative feeding and data logging. Choose by production environment: Carbon steel or stainless steel with standard seals are available for standard environments; customized equipment is available for special environments. Explosion-proof applications like chemical and lithium battery applications require ATEX-certified models with anti-static and nitrogen protection. Aseptic applications like pharmaceutical and food applications require 316L stainless steel.

Why choose us as your pellet vacuum loader supplier?

Among many equipment suppliers, we have established ourselves as a long-term partner to numerous companies worldwide thanks to our professional technical expertise, reliable quality assurance, and attentive service.

Extensive Industry Experience: With over 10 years of dedicated experience in pellet conveying, spanning industries such as plastics, food, pharmaceuticals, chemicals, and new energy, we have a deep understanding of the challenges of conveying diverse materials. With a wealth of proven case studies and experience providing customized solutions for numerous companies, our equipment offers stable operation and proven performance.

Highly Customizable: As a custom design manufacturer, we can provide customized solutions tailored to each customer's material characteristics, production environment, and space constraints. Flexible configurations are available, with materials including carbon steel, 304/316L stainless steel, and PP anti-corrosion. Features include anti-static, dust removal, nitrogen protection, and CIP cleaning.

Excellent Product Quality: Core components utilize imported, high-quality parts to ensure long-term, stable operation. Every unit undergoes continuous testing before shipment, achieving a 100% pass rate.

In industrial production, the conveying of granular materials is an essential component across many industries. From plastic and rubber pellets to feed and building material pellets, achieving fast, clean, and stable conveying directly impacts production efficiency and product quality. As a conveying device specifically designed for granular materials, the granular vacuum conveyor, with its unique advantages, is becoming an ideal solution for granular conveying in various industries.