Single blade mixer

The single blade mixer is a common horizontal stirring and mixing equipment. Its main feature is that a horizontal rotating shaft is installed in a horizontal cylinder (usually a U-shaped groove), and multiple blades are fixed on the shaft.

Contact Materials: >304 Stainless Steel 316 optional Interior Surfaces: Polished 180 Grit Support Steel: 304 or 316 Stainless Steel Working Capacities: 3 to 10,000 Cubic Feet

What is a single blade mixer?

Single blade mixer is a common industrial mixing equipment, mainly used for mixing materials such as powder and powder, powder and a small amount of liquid. Its core component is a stirring shaft equipped with a single spiral blade, usually in the shape of a spiral ribbon or paddle, installed inside a horizontal or vertical cylinder, and driven by a motor to rotate the stirring shaft, so that the material is repeatedly flipped, sheared and diffused in the cylinder, so as to achieve the purpose of uniform mixing.

Scope of application

Mixing of dry materials such as flour, starch, additives, and carbon powder;

Basic mixing of granules and powdered pesticides;

Uniform mixing of lightweight powders such as flavors and seasoning powders;

Premixing of dry materials such as dry mortar and thermal insulation mortar.

Difference between single blade mixer and double-blade mixer

Single blade mixer and double-blade mixer are common industrial mixing equipment, which mainly achieve the purpose of mixing materials by rotating the blades. The main difference between the two is the number of stirring shafts and the configuration of the blades, which directly affects their mixing principles, efficiency, and scope of application.

| Comparison project | Single blade mixer | Double blade mixer |

| Image |

|

|

| Structural features | Equipped with a stirring shaft equipped with a single blade | Equipped with one or two stirring shafts equipped with two symmetrical blades |

| Mixing method | One-way push, material flows in one direction in the cylinder | Two-way counter-pushing, material forms tumbling convection |

| Mixing principle | Through the rotation of a single blade, the material flows and achieves mixing | Two blades rotate relative to each other, generating a complex material flow field and promoting mixing |

| Mixing effect | The mixing speed is relatively slow, and the uniformity may be slightly lower | The mixing speed is fast, which can make the material mix more evenly |

| Applicable materials Material | Suitable for some materials with low requirements for mixing uniformity and good fluidity | Widely used in various materials, including materials that are difficult to mix due to viscosity and large differences in particle size |

| Energy consumption | Relatively low, because there is only one blade drive | Relatively high, it is necessary to drive two blades to rotate, but high efficiency and energy saving can be achieved when the power configuration is reasonable |

| Applicable scenarios | Small batch production or processes with low mixing requirements | Scenarios with high process requirements and large output |

Working principle of single blade mixer

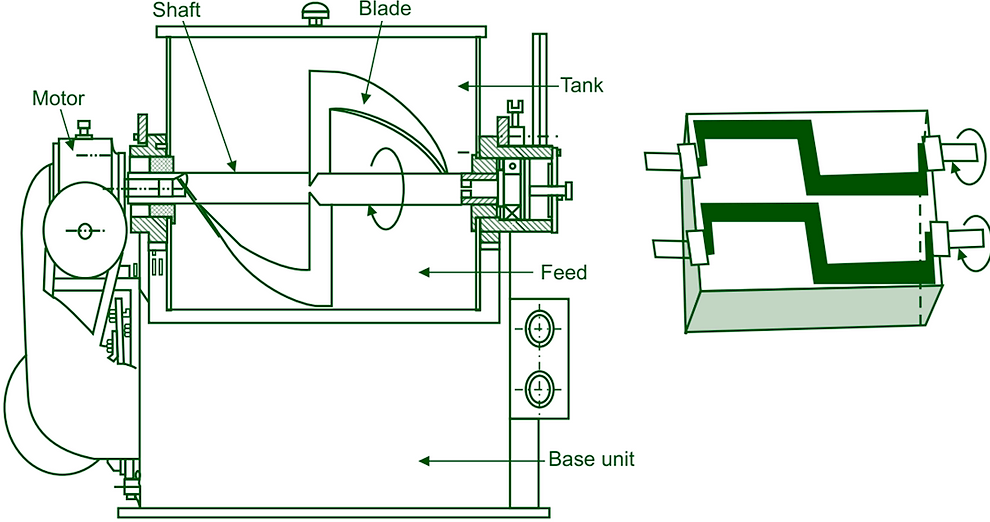

Single blade mixer usually consists of a horizontal U-shaped trough, a central rotating shaft and multiple blades fixed on the shaft.

①When working, the material is added to the mixing trough, and the motor drives the central shaft to rotate, driving the blade to move.

②When the motor is started, the material is driven in the cylinder to form a variety of composite motion forms such as up and down flipping, axial flow, radial diffusion, etc., so that materials of different particle sizes or densities can be evenly mixed.

③The design and arrangement of the blades make the material produce radial, tangential and axial movements in the trough, and the uniform mixing of materials of different components is achieved by lifting, rolling, shearing and diffusing the material. The angle and shape of the blade can be adjusted according to different material characteristics and mixing requirements.

The structure of single blade mixer

What are the advantages of a single blade mixer?

1. Solve the problem of uneven material mixing

In traditional mixing equipment, materials may be unevenly mixed due to differences in particle size, morphology or insufficient mixing time. The single blade mixer can provide uniform shearing, mixing and flipping through its unique blade design. This design ensures that the materials can be fully stirred during the mixing process and avoids uneven material distribution.

2. Deal with material adhesion or agglomeration

During the mixing process of some highly viscous or wet materials, adhesion or agglomeration is prone to occur. The single blade mixer can effectively break the viscous structure of the material through efficient stirring power, reducing adhesion and agglomeration between materials. In addition, some single blade mixers are also equipped with heating or cooling systems to help control the temperature of the material and further reduce the adhesion problem.

3. Solve particle breakage

Some materials, especially fragile particles, are easily broken during the mixing process. The working mode of the single blade mixer can avoid excessive mechanical pressure and reduce the breakage rate of particles through the gentle collision of the blade design and the material, which is particularly suitable for handling fragile or sensitive materials.

4. Difficulty in handling bulk materials

In large-scale production, how to handle large amounts of materials efficiently and stably is a difficult problem. Single blade mixers are usually designed with larger capacity, which is suitable for handling bulk materials. At the same time, their continuous and stable mixing effect ensures consistency and stability in large-scale production, meeting the requirements of industrial production.

Technical parameters of Single blade mixer

| Model | VH2 | VH5 | VH8 | VH10 | VH14 (single arm) | VH14 (double arm) |

| Full volume (L) | 2 | 5 | 8 | 10 | 14 | 14 |

| Net volume (L) | 0.8 | 2 | 3.2 | 4 | 5.6 | 5.6 |

| Loading coefficient | 40% | 40% | 40% | 40% | 40% | 40% |

| Maximum loading (Kg) | 1 | 2.5 | 4 | 5 | 5.6 | 5.6 |

| Optimum loading (Kg) | 0.6 | 1.4 | 2.2 | 2.8 | 4.2 | 4.2 |

| Diameter of cylinder (mm) | φ100 | φ133 | φ160 | φ160 | φ160 | φ160 |

| Feed port diameter (mm) | φ57 | φ76 | φ76 | φ108 | φ108 | φ108 |

| Discharge port diameter (mm) | φ57 | φ76 | φ76 | φ76 | φ76 | φ76 |

| Motor power (Kw) | 0.04 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 |

| Speed (r/min) | 28 | 24 | 24 | 24 | 20 | 20 |

| Dimensions (length, width and height, mm) | 475×205×380 | 720×350×610 | 810x350x625 | 850x350×785 | 925×350×825 | 930×350×840 |

| Model | VH20 (One-arm) | VH20(two-arm) | VH30(one-arm) | VH30(two-arm) | VH50 | VH100 |

| Full volume (L) | 20 | 20 | 30 | 30 | 50 | 50 |

| Net volume (L) | 8 | 8 | 12 | 12 | 20 | 40 |

| Loading coefficient | 40% | 40% | 40% | 40% | 40% | 40% |

| Maximum loading (Kg) | 10 | 10 | 15 | 15 | 25 | 50 |

| Optimum loading (Kg) | 5.6 | 5.6 | 8 | 8 | 14 | 28 |

| Diameter of cylinder (mm) | φ220 | φ220 | φ225 | φ225 | φ300 | φ355 |

| Feed port diameter (mm) | φ133 | φ133 | φ133 | φ133 | φ160 | φ160 |

| Discharge port diameter (mm) | φ76 | φ76 | φ76 | φ76 | φ80 | φ100 |

| Motor power (Kw) | 0.75 | 0.55 | 0.75 | 0.75 | 0.75 | 1.1 |

| Speed (r/min) | 20 | 20 | 20 | 20 | 20 | 15 |

| Dimensions (length, width, height, mm) | 950×350×830 | 1195×350×885 | 990×350×860 | 1170×370×1015 | 1350×460×1160 | 1580×650×1460 |

Application of single blade mixer

Feed industry: In the production of compound feed and premixes, single blade mixers are widely used in the mixing process of various raw materials such as corn flour, soybean meal, additives, etc. It has strict requirements on the proportion of ingredients, and the mixing uniformity directly affects the quality of feed.

Chemical industry: In the fine chemical, additive, dye, coating and other industries, mixers are used for uniform mixing of various solid materials, and sometimes also small doses of liquid additives. They can mix dry powder and granular chemical raw materials and are suitable for premixing processes of powder formulas.

Building materials industry: In mixing processes such as dry mortar, thermal insulation materials, putty powder, etc., mixers can achieve efficient and uniform mixing to meet the requirements of mass production. They are suitable for mixing dry mortar, gypsum, fillers, and processes containing a small amount of water or adding liquid components.

Pesticide and fertilizer industry: In the production of powdered pesticides, compound fertilizers, and bio-organic fertilizers, single blade mixers are used for premixing of basic raw materials or additives. They can achieve uniform dispersion of trace ingredients and are suitable for mixing processes of corrosive or water-containing raw materials.

In summary, single blade mixers are economical and practical mixing equipment. With their simple and reliable design, they are widely used in powder and granule mixing, especially in cost-sensitive or medium mixing scenarios. However, more complex equipment may be required when dealing with high viscosity or high uniformity requirements.