Vertical conical spiral mixer

Vertical conical spiral mixer is suitable for mixing solid and powder materials, especially for short-time mixing and industrial homogenization of powdered and similar particle size materials, which can maintain the material form and achieve thorough discharging. The mixer allows liquid to be added during the process.

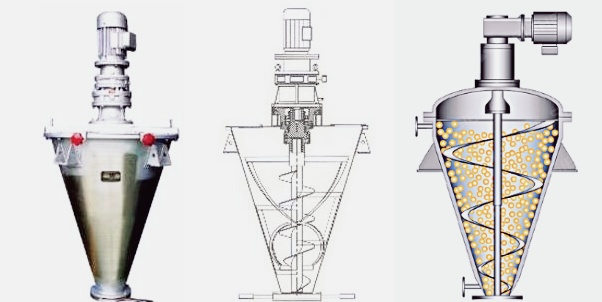

What is a vertical conical spiral mixer?

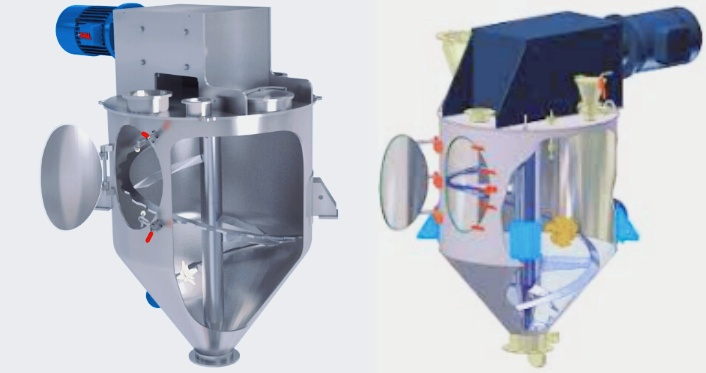

Vertical conical spiral mixer is a kind of equipment used for mixing powders, granules or viscous fillings, which is widely evaluated in chemical, pharmaceutical, food, building materials and other industries. Its main features are the vertical conical container design, internal spiral ribbon stirring device, and the up and down flipping of the warehouse and uniform mixing through the rotational motion of the spiral. It adopts a vertical direction, which is different from other types of mixers such as horizontal mixers. Vertical conical spiral mixers are especially suitable for pharmaceutical, food, chemical and other industries where uniform mixing of ingredients is crucial. They are especially suitable for mixing large quantities of granular or powdered materials.

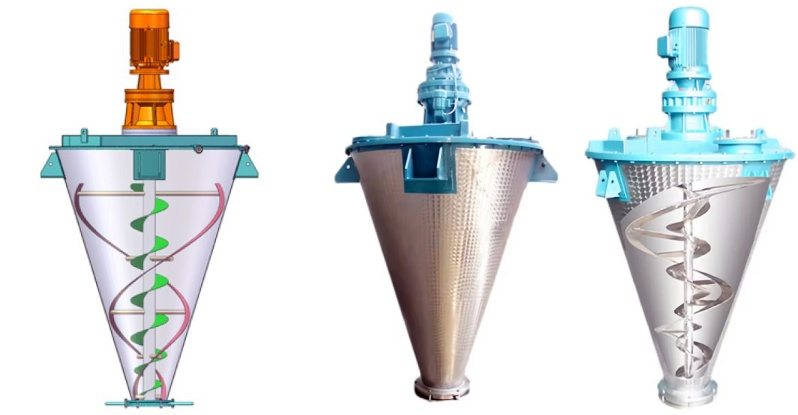

Classification of vertical conical spiral mixers

| Types | Picture | Features | Applicable scenarios | Main differences |

| Single-screw conical mixer |

|

Single screw rotates to push materials, low maintenance cost | Small batch, low viscosity material mixing (such as powder, granules) | Low mixing efficiency, suitable for simple process requirements |

| Twin-screw conical mixer |

|

Bidirectional screws rotate in opposite directions to form convection mixing, high efficiency | Medium and high viscosity materials, high uniformity requirements (such as adhesives) | More uniform mixing, but complex structure and high energy consumption |

| Multi-screw conical mixer |

|

Three or more screws work together, high mixing intensity | High viscosity, high filling rate materials (such as ceramic slurry) | Narrow scope of application, high customization requirements |

Scope of application of vertical conical spiral mixer

Powdered materials: such as flour, cement powder, medicinal powder, etc., the particle size range is usually from a few microns to a few millimeters.

Granular materials: such as plastic particles, feed particles, ore particles, etc., the particle size is generally 0.1~20 mm.

Mixed materials: powder-powder, powder-granule, granule-granule mixing, allowing a small amount of liquid to be added (such as spray humidification, oily additives).

Scope of application: suitable for powders, granules, and materials with low viscosity, such as chemical raw materials, pharmaceutical powders, food additives, plastic granules, etc.

Working principle of vertical conical spiral mixer

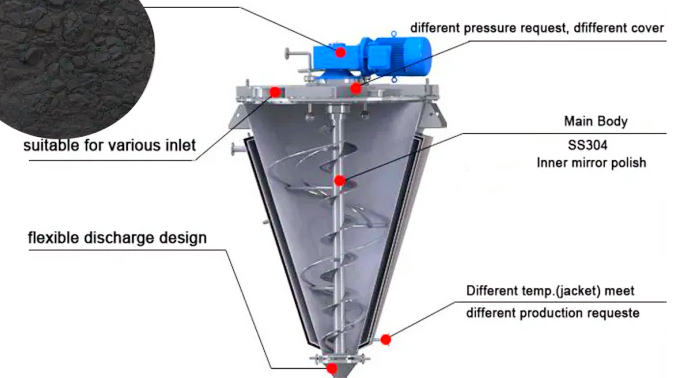

① Structure: The equipment consists of a conical barrel, a spiral agitator, a drive motor, a transmission device, etc. The barrel is conical with a wide top and a narrow bottom, and there is usually a discharge port at the bottom.

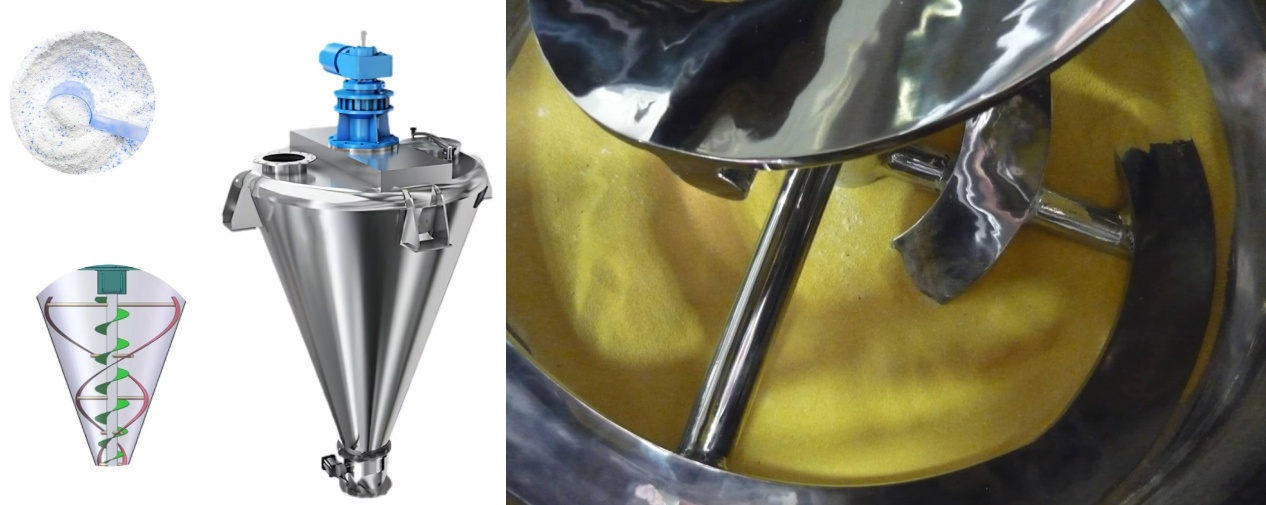

② Process: The motor drives the spiral agitator to rotate and mix, and the spiral ribbon will form a lifting belt that is lifted from the bottom along the barrel wall. At the same time, due to gravity, it slides along the conical wall, convection and shear motion, thereby achieving uniform mixing. The material enters the conical barrel from the top or bottom of the equipment. As the spiral blades rotate, the material is continuously lifted, flipped and sheared, forming a multi-dimensional motion of "throwing, falling, and tumbling" to achieve rapid and uniform mixing. The combination of the conical barrel and the spiral blades can reduce dead corners and material backlogs and ensure the mixing effect.

③ Discharge: After the mixing is completed, feedback is given through the bottom discharge valve.

Structure of the vertical conical spiral mixer

Vertical design: The equipment is placed vertically, with a small overall footprint, suitable for production environments with limited space.

Conical barrel: The mixing container has a conical or inverted conical structure. This shape is conducive to the bottom-up flow of materials during the mixing process and improves the mixing uniformity.

Spiral blades (spiral blades): Spiral blades mounted on the main shaft, usually including two layers of inner and outer spiral blades, rotating in opposite directions or in the same direction, responsible for the lifting and flipping of materials, and promoting the formation of multi-directional flow of materials in the barrel.

Main shaft and transmission device: The main shaft is installed vertically to drive the spiral blades to rotate to achieve material mixing and conveying.

What are the advantages of the vertical conical spiral mixer?

The mixing time is short, up to 10 minutes. The rotation of the vertical conical spiral mixer is driven by a bevel gear motor to ensure high output and quiet operation of the entire motion chain.

Repeatable mixing process, repeatable and easy to scale up. Compared with common vertical spiral mixers, the vertical conical spiral mixer has a mixing shaft support separated from the gear motor, which can be replaced without disassembling the mixing shaft, thus reducing maintenance time and cost.

High mixing uniformity: suitable for scenarios with high uniformity requirements (such as medicine, food additives), with a uniformity of more than 99%. The spiral mixer is supported by a ribbed die-cast food-grade aluminum frame and is centered only on the top of the mixer. The frame contains two large ball bearings with solid spacing. This solution provides an effective connection for the mixing shaft.

Technical specifications of vertical conical spiral mixer

| Model | geometric volume (Lt) | effective volume (L) | max load (kg) | power (kW) | A | B | C | D | E |

| DHC100 | 105 | 100 | 100 | 1.5 | 654 | 970 | 890 | 720 | 200 |

| DHC200 | 230 | 200 | 200 | 2,2 | 658 | 1255 | 970 | 720 | 200 |

| DHC340 | 430 | 340 | 340 | 3 | 808 | 14 05 | 1045 | 920 | 200 |

| DHC600 | 650 | 600 | 600 | 5,5 | 1008 | 1720 | 1330 | 1150 | 200 |

| DHC1000 | 1200 | 1000 | 1000 | 7,5 | 1108 | 2020 | 1330 | 1250 | 250 |

Application of vertical conical spiral mixer

Vertical conical spiral mixer is widely used for mixing powder, granules, paste and high viscosity materials due to its unique conical structure and spiral design.

Chemical industry: used for mixing various chemical raw materials, such as mixing plastic particles with additives, which can make the additives evenly dispersed in the plastic particles and improve the performance of plastic products; in the production of coatings, it can fully mix liquid components such as pigments, fillers and resins.

Pharmaceutical industry: In the production of medicines, it can be used to mix different drug ingredients, such as mixing various powdered drug raw materials into compound preparations to ensure the quality and efficacy of drugs; it can also be used to mix drug powders with an appropriate amount of adhesive solution to make soft materials with a certain viscosity.

Food industry: It can be used to mix various food raw materials, such as in the production of seasonings, powdered raw materials such as salt, sugar, monosodium glutamate, spices, etc. are mixed evenly; in the production of baked foods such as bread and biscuits, flour, sugar, yeast, oil and other raw materials are mixed.

Building materials industry: It is often used in the production of dry mortar, insulation mortar, premixed mortar, etc., to mix powder materials such as cement, sand, lime, additives, etc.; it can also be used in the production of putty powder to fully mix raw materials such as calcium carbonate, talcum powder, cellulose, etc.

Pesticide industry: It can mix pesticide raw materials with fillers, additives, etc. to make pesticide products of various dosage forms, such as wettable powders, powders, etc., so that the pesticides can be evenly dispersed when used, improving the efficacy and prevention and control effects of the pesticides.

Selection suggestions for vertical conical spiral mixers

1. Production capacity: According to the production scale and output requirements of the enterprise, select a mixer with appropriate volume and processing capacity. Generally speaking, enterprises with larger production scales should choose large-capacity mixers to improve production efficiency and meet production needs.

2. Material characteristics

Particle size: For materials with smaller particle sizes, it is necessary to select a mixer with greater stirring intensity and finer ribbon structure to ensure that the materials can be fully mixed; for materials with larger particle sizes, a mixer with larger ribbon spacing and stronger stirring force can be selected to prevent material blockage and excessive crushing.

Flowability: For materials with good flowability, a conventional vertical conical spiral mixer can be selected; for materials with poor flowability, such as viscous or hygroscopic materials, a mixer equipped with heating, cooling or liquid spraying devices can be considered to improve the flowability of the materials and improve the mixing effect.

Density: When the density of the mixed materials varies greatly, a mixer with stronger stirring and dispersing capabilities should be selected so that materials of different densities can be evenly mixed to avoid stratification.

3. Mixing accuracy: If the uniformity of the mixed materials is required to be high, such as in the pharmaceutical, electronic and other industries, it is necessary to select a mixer with high mixing accuracy and good mixing uniformity, and it can be equipped with corresponding detection and control devices, such as online concentration detectors, automatic control systems, etc., to ensure the mixing quality.

4. Material requirements: Select the appropriate mixer material according to the nature of the material and the use environment. For industries such as food and medicine, stainless steel materials that meet hygiene standards, such as 316L stainless steel, should be selected to prevent the material from being contaminated; for materials with strong corrosiveness, corrosion-resistant materials, such as titanium alloys, should be selected.

5. Supporting facilities: Consider the matching connection between the mixer and upstream and downstream equipment, such as feeding equipment, discharging equipment, conveying equipment, etc. Ensure smooth connection and coordinated operation between the equipment to improve the automation and production efficiency of the entire production system.

Vertical conical spiral mixer supplier

Vertical conical spiral mixer is a mixing equipment widely used in chemical, food, pharmaceutical, building materials and other industries, suitable for uniform mixing of powder and granular materials. Dahan Machinery is a well-known supplier of vertical conical spiral mixers, providing high-quality mixing equipment. If you need specific product information or technical parameters, you can contact our sales team for more details.

Conical barrel design: Reduce material residue and reduce the risk of cross contamination, especially suitable for industries with high hygiene requirements such as food and medicine.

Spiral mixing system: Adopt double spiral ribbon or single spiral ribbon structure, through the combination of rotation and revolution, to achieve fast and uniform mixing.

Sealing performance: Equipped with mechanical seal or gas seal device to prevent dust leakage.

Customized service: Provide standardized products with different volume specifications, and can also customize materials (such as 304/316L stainless steel), spray system, etc. according to customer needs.