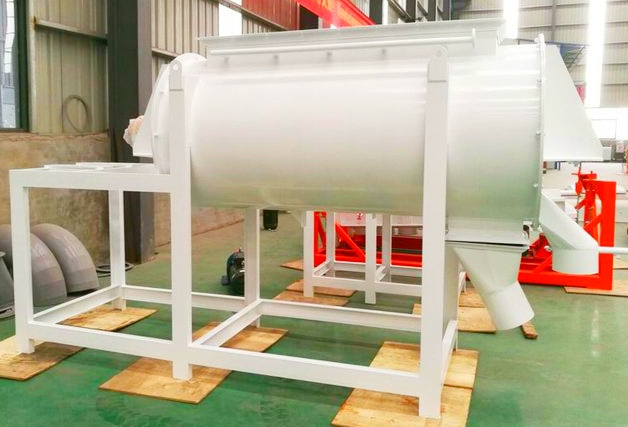

Double blade mixer

Double blade mixers are used for dry and wet mixing of granular and powdered materials. The blade design ensures high mixing action, resulting in an even distribution of important nutrients, vitamins and minerals in the granular mixture. The equipment is used to mix different powder and granular ingredients with or without the addition of liquid in food, premixes, pet food, aquafeed and animal feed production.

Delivery volume: 9-134.2m³/h Speed: 60r/min

What is a double blade mixer?

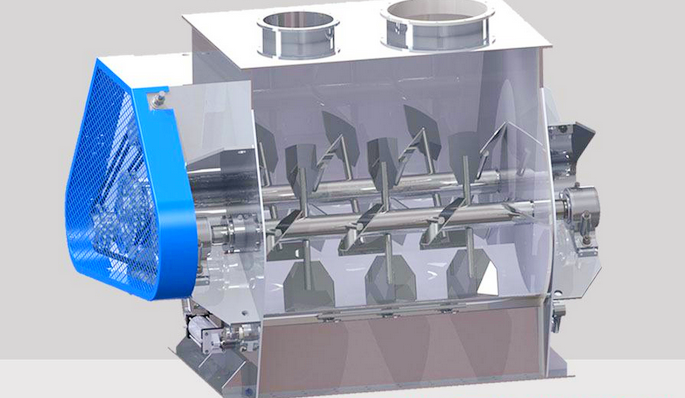

Double blade mixer is an industrial mixing device that uses two parallel shafts with blades to mix a variety of materials. The blades rotate in opposite directions, resulting in a violent mixing action that can quickly and efficiently mix powders, granules, liquids and even viscous materials. Efficient mixing is achieved through dual-shaft counter-rotating blades. The core design is that two parallel-mounted stirring shafts rotate synchronously in opposite directions. The blades quickly mix different materials to a highly uniform state through shear, convection and diffusion.

Applicable materials for double blade mixers

Dry mortar, thermal insulation mortar, tile adhesive, etc.

Coating additives, pigments, laundry detergent, fertilizers, etc.

Milk powder, flour premix, seasoning, etc.

Powder ratios such as premixes and concentrates

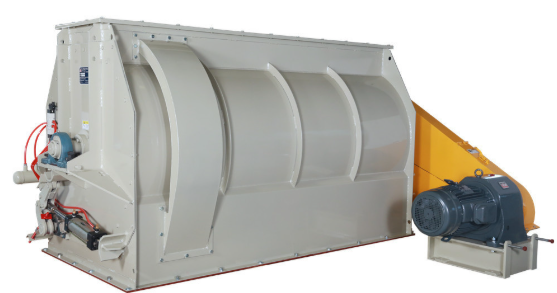

Classification of double blade mixers

| Mixer type | picture | Structural form | Drive mode | Application characteristics and usage instructions |

| Double blade mixer |

|

Double shaft blade type | Double shaft reverse synchronous drive | Through material throwing to form a "weightless zone", the mixing uniformity is high, suitable for powders, particles, liquid-solid mixing and other materials |

| Single-shaft blade mixer |

|

Single shaft blade type | Single motor drive | Simple structure, small footprint; through shorter mixing time and high Efficiency improves product quality |

| Double shaft ribbon mixer |

|

Double shaft ribbon type | Chain and gear linkage drive | Two sets of ribbons rotate in opposite directions to achieve synchronous mixing movement; suitable for large-scale mixing and small material stratification |

| Single-shaft ribbon mixer |

|

Single shaft ribbon type | Motor direct or reduction drive | It is a high-shear mixer, suitable for rapid mixing of materials such as aquatic feed, animal feed, pet food, etc. |

Working principle of double blade mixer

Double blade mixer mainly shears, squeezes, flips and sprinkles the materials in the mixing chamber through the relative movement of the blades installed on two parallel shafts, thereby achieving uniform mixing of the materials. Its working principle can be summarized as follows:

① Mechanical stirring and convection mixing: The two shafts usually rotate in opposite directions, and the blades installed on them also move accordingly. The rotating blades push the materials to make circular motion in the mixing chamber, and at the same time, due to the angle and shape design of the blades, they also guide the materials to produce axial flow.

② Shearing and dispersion effect: The relative movement between adjacent blades and between the blades and the inner wall of the mixer will produce shear force on the materials. This shear force can effectively destroy the agglomeration of materials, especially for materials with a certain viscosity, it can disperse them and improve the uniformity of mixing.

③ Extrusion and penetration: The paddles will exert a certain extrusion force on the materials during movement. This extrusion force helps to press and penetrate materials of different components against each other, especially when mixing materials with large density differences, it can reduce stratification.

④ Sprinkling and gravity mixing: The high-speed rotating paddles will throw the materials into the air, allowing them to scatter freely under the action of gravity.

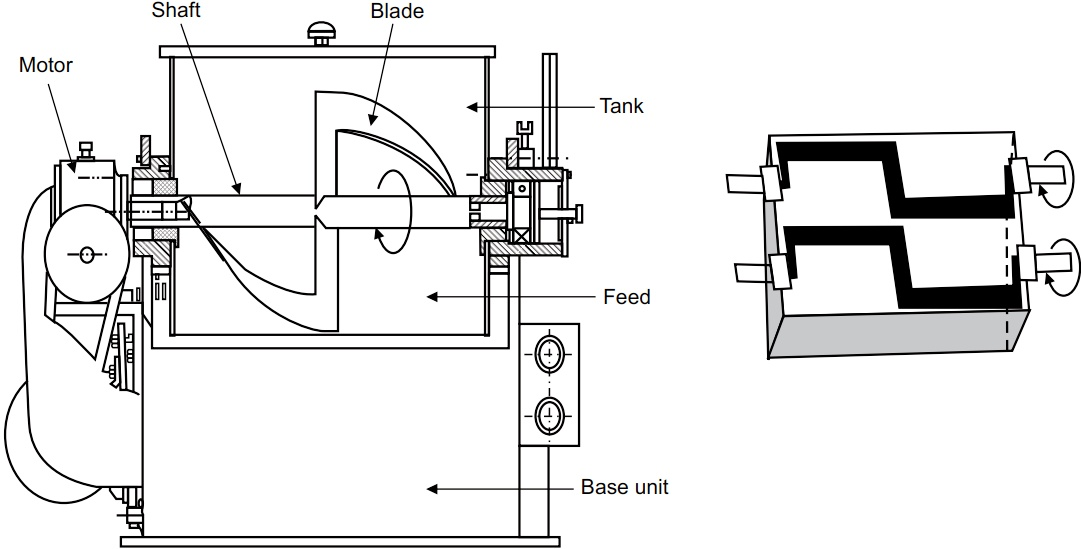

Structural composition of the double blade mixer

The double blade mixer is mainly composed of the following parts:

Frame: The structure that supports the entire mixer, usually made of steel to ensure stability and durability.

Mixing barrel: A container for placing materials to be mixed, and the barrel body is usually made of stainless steel or other corrosion-resistant materials.

Double blade agitator: It consists of two paddles, which can effectively stir and mix materials. The shape and angle design of the paddles affect the mixing effect.

Drive system: It includes a motor and a reducer, which is responsible for driving the paddles to rotate to achieve mixing.

Feed and discharge ports: convenient for the entry and exit of materials, usually designed with sealing devices to prevent material leakage.

Control system: used to adjust parameters such as mixing speed and time to ensure precise control of the mixing process.

Safety devices: including overload protection, emergency stop switch, etc. to ensure safe operation. These components work together to achieve efficient material mixing.

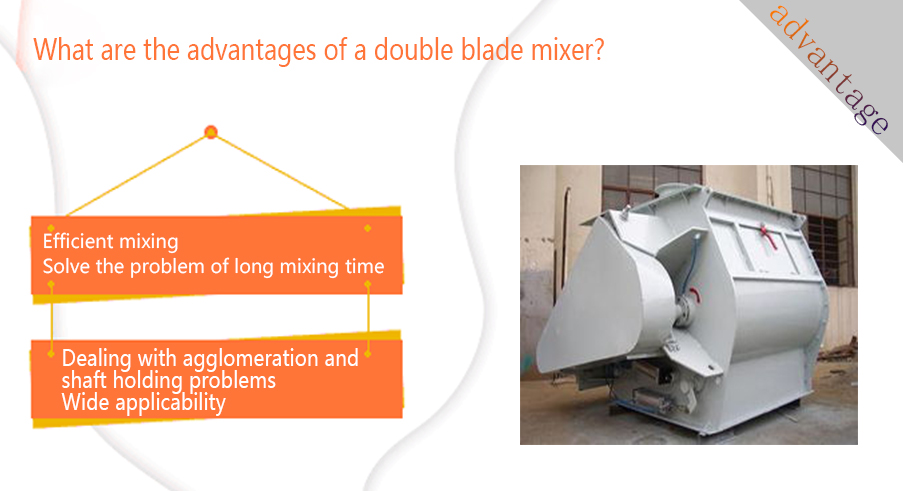

What are the advantages of a double blade mixer?

Efficient mixing: Two parallel mixing shafts are equipped with multiple sets of mixing blades. Through relative movement, the double blade mixer can strongly shear, squeeze and flip the materials to achieve fast and uniform mixing.

Solve the problem of long mixing time: The double shaft design provides a larger mixing power input, which can disturb and mix the materials more violently in a shorter time. The shape, angle and arrangement of the mixing blades are optimized to maximize the mixing efficiency and shorten the mixing cycle.

Dealing with agglomeration and shaft holding problems: When mixing wet or sticky materials, it is easy for materials to agglomerate or entangle on the mixing shaft and blades, reducing the mixing efficiency. By optimizing the distance between the blades and the speed of the mixing shaft, the accumulation of materials on the shaft can be reduced. Some double blade mixers are equipped with scrapers to scrape off materials adhering to the wall of the drum to prevent them from forming lumps and re-mixing.

Wide applicability: It can mix various types of materials, including dry hard, semi-dry hard, plastic and concrete of various proportions, and is also suitable for mixing other powdery, granular or fibrous materials. By adjusting the speed of the stirring shaft and the angle of the blades, the intensity of the mixing can be controlled to meet the mixing needs of different materials.

Technical parameters of double blade mixer

| Model | Effective volume (L) | Motor power (kW) | Equipment weight (kg) | Dimensions (mm) |

| WLDH-500 | 500 | 7.5 | 1200 | 2200×1000×1300 |

| WLDH-1000 | 1000 | 11 | 1500 | 2600×1100×1400 |

| WLDH-2000 | 2000 | 18.5 | 2500 | 3200×1300×1600 |

| WLDH-3000 | 3000 | 22 | 3200 | 3600×1500×1800 |

What is a double blade mixer used for?

Double blade mixer is an efficient intermittent mixing equipment that uses two main shafts with paddles to rotate synchronously. The paddles flip and lift the materials to achieve a fast and uniform mixing effect. The equipment is suitable for mixing a variety of materials, especially for materials with high moisture content, large density differences or that need to be mixed quickly.

① Dry mortar production line: used to mix dry powder materials such as cement, sand, fly ash, gypsum, and admixtures.

② Sludge and lime mixing: used for sludge stabilization treatment, dehydrating and disinfecting the sludge by mixing lime and neutralizer.

③ Seasoning production: such as mixing chicken essence, chili powder, pepper powder and other spices, requiring no destruction of particle shape and uniform mixing.

④ Cold regeneration pavement material mixing: used in asphalt pavement cold regeneration construction, mixing old asphalt, cement, regeneration agent, etc.

Use and maintenance suggestions for double blade mixers

Before starting the machine, check whether the connection of each component is firm and whether the lubrication is good; check whether the oil level of lubrication parts such as reducers and bearings is normal, and add lubricating oil if necessary.

Avoid overloading during mixing, strictly follow the rated capacity of the equipment to produce, avoid long-term overload operation, so as not to damage the motor and mechanical parts.

Avoid putting materials that are too large or contain hard impurities directly into the mixer, and pre-treat them if necessary; try to ensure that the materials enter the mixing chamber evenly to avoid local accumulation.

Clean the inner wall of the cylinder and the blades regularly to avoid material residue and agglomeration; clean the residual materials on the inner wall of the mixing chamber and the mixing blades every day or after each use to keep the equipment clean.

The bearing grease should be replaced every 500 hours of operation.