Dust-free feeding and powder feeding system of dough mixer

Wednesday June-25 2025 16:26:45

Dust-free feeding and powder feeding system of dough mixer is specially designed for pasta and baking industry. It integrates three functions: dust-free feeding, precise conveying and automatic weighing, which completely solves the dust pollution, inaccurate proportion and low efficiency in traditional flour processing. It adopts fully enclosed pipeline transportation, meets food-grade hygiene standards, and works with dough mixer to adjust the powder-water ratio to ensure dough consistency.

Advantages of Dust-free feeding and powder feeding system of dough mixer

This integrated system realizes dust-free operation of the whole process from feeding to dough mixing through enclosed conveying and intelligent weighing technology, which improves efficiency by 300% compared with traditional methods.

Patented sealed impurity removal: The patented labyrinth sealing structure is adopted to achieve dust leakage of <1mg/m³, which far exceeds the industry standard and effectively ensures the cleanliness of the workshop environment. The integrated vibrating screen has a 1mm impurity removal accuracy and can quickly separate foreign matter from raw materials.

Gentle conveying: Equipped with vacuum conveying system and low shear venturi generator to ensure flour breakage rate <0.1% and protect raw material quality.

Precise weighing and batching: The weighing and proportioning unit is equipped with a dynamic compensation weighing module to achieve high-precision measurement of ±0.3%, support multi-component synchronous batching, and can process up to 8 kinds of raw materials.

Intelligent linkage: Through the linkage control system, the feed amount can be adjusted in real time in linkage with the dough mixer speed to ensure smooth production process.

Dust-free feeding and powder feeding system of dough mixer principle

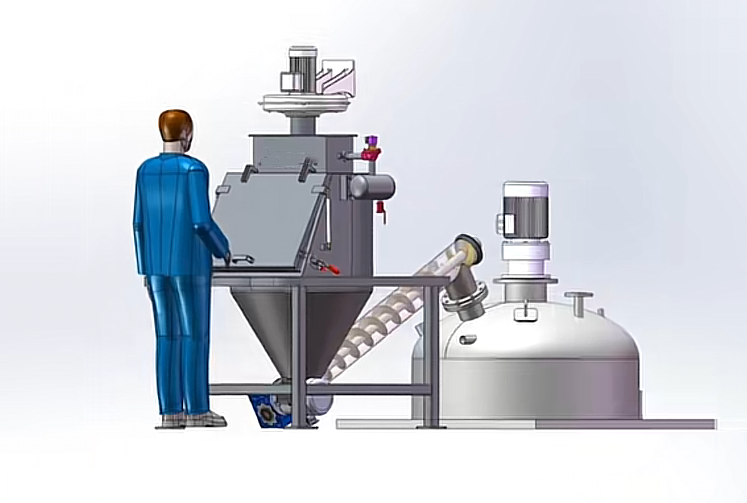

The dust-free feeding and powder feeding system of dough mixer is mainly composed of dust-free feeding station, conveying pipeline, metering device and control system. The dust-free feeding station is the core, adopts a closed design, and uses negative pressure gas adsorption or compressed air to suck and transport powder materials to the dough mixer feed port. When feeding, the dust collection fan collects dust to the high-density filter element, and the backflush system regularly pulses and cleans it, so that the dust is sieved and recovered, avoiding raw material loss and extending the life of the filter element. The special material and design of the conveying pipeline reduce friction and residue, ensuring efficient and smooth transportation. The metering device accurately controls the feeding amount, and the control system realizes automatic and intelligent operation, significantly improving production efficiency and feeding accuracy.

Dust-free feeding and powder feeding system of dough mixer multi-scenario adaptation solution

The system integrates closed feeding, vacuum conveying and dynamic weighing technology to achieve dust-free processing of flour from unpacking to mixing, supporting different scale scenarios such as central kitchen, chain baking, quick-frozen dough, etc.

Baking industry: In view of the characteristics of different raw materials such as high-gluten flour and low-gluten flour, the system is equipped with a grading screening device to remove agglomerated particles through an 80-200 mesh screen to ensure uniform dough gluten.

Quick-frozen food production: In the production of quick-frozen dumplings and glutinous rice balls, the system integrates a temperature and humidity control system, and the conveying pipeline is equipped with a heating belt and a dehumidification module to prevent the flour from getting damp and agglomerating. At the same time, it is linked with the dough mixer PLC system to achieve "flour-water-additive" simultaneous feeding.

Bread industry: The flour is fed into the vibrating screen through the dust-free feeding station and then conveyed to the mixer through the vacuum feeder. The whole process is dust-free and pollution-free, fully ensuring the hygiene of the bread raw materials.

What equipment can be used in combination with the dust-free feeding and powder conveying system of the dough mixer?

The dust-free feeding and powder conveying system of the dough mixer can be efficiently combined with a variety of equipment such as inline screens and mixers with its strong compatibility and integration capabilities to further optimize the food production process.

Combined with inline screens: Before raw materials such as flour enter the dough mixer, the inline screen can finely screen them. The inline screen can quickly separate the agglomerated particles and impurities in the raw materials to ensure the purity of the materials entering the dust-free feeding and powder conveying system.

Combined with mixers: When production requires the addition of multiple raw materials (such as flour, yeast, sugar, salt, etc.), the dust-free feeding and powder conveying system can first accurately convey the flour to the mixer, and then fully mix it with other raw materials added through the metering device. The mixer realizes the uniform mixing of multiple materials, and the dust-free feeding and powder conveying system ensures the efficiency and cleanliness of flour conveying. The two work together to make the dough raw materials more evenly mixed and improve the taste and quality of the final product.

Dust-free feeding and powder feeding system of dough mixer manufacturer

Dahan Machinery has been focusing on the research and development of food processing equipment for many years. We have gathered top technical talents and relied on advanced R&D laboratories to continuously innovate system technology. The dust-free feeding and powder feeding system produced by the company has a patented labyrinth seal structure to ensure that dust leakage is less than 1mg/m³, and the integrated vibration screen has an impurity removal accuracy of 1mm to ensure the purity of the material. Vacuum conveying is matched with a low-shear Venturi generator, and the flour breakage rate is less than 0.1%. From solution customization, equipment production, to installation and commissioning, and after-sales maintenance, we provide one-stop service, and provide a series of systems such as screening machines, mixers, dust-free feeding stations, and vacuum feeders to provide customized services.

The dust-free feeding and powder feeding system of dough mixers has broad application prospects in the field of food processing with its advantages of high speed, safety, cleanliness, flexibility and traceability. With the continuous advancement of technology and the continuous expansion of the market, this system will bring more convenience and value to the food processing industry.