Industrial Vacuum Loading Machine

Industrial Vacuum Loading Machine is used for automated conveying of dry materials such as powdered and granular materials. As an indispensable material handling device in modern industrial production, it uses the negative pressure generated by a vacuum pump to transport materials from one location to another.

Power: 1.5-5.5kw (customizable)

Dimensions (length * width * height): Depends on the specific model

Material: Stainless steel / carbon steel

Voltage:220V / 380V / 415V or according to order

ustomization: Acceptable

Type:Pneumatic / Electric / Continuous

Core components:Motor, bearing, gear, pump, gearbox, engine

Scope of application: Conveying materials such as flour, wheat flour, sugar, milk powder, seasoning, coffee beans, etc.

What is an Industrial Vacuum Loading Machine?

Industrial Vacuum Loading Machine uses suction generated by a vacuum pump to transfer materials within a closed pipe. It perfectly replaces traditional manual feeding methods and completely eliminates dust pollution, cross-contamination, and material loss during the production process. Customizable configurations are available based on different material characteristics and process requirements. Made of high-quality stainless steel, it is an ideal choice for improving production efficiency and ensuring product quality.

What are the advantages of an Industrial Vacuum Loading Machine?

The Industrial Vacuum Loading Machine utilizes a closed, negative pressure conveying principle to completely eliminate the dust pollution problem associated with powder handling. Equipped with a filtration system for dust-free operation, the machine's intelligent PLC control enables fully automated operation.

Fully enclosed conveying: This prevents material from coming into contact with the outside world and dust from escaping, ensuring compliance with standards.

Improves the working environment: This reduces dust in the workshop, protecting worker health. It is suitable for handling toxic, explosive, or high-purity materials.

Reduces material loss: The closed system recovers residual dust, minimizing raw material waste, making it particularly suitable for high-value materials. Continuous Conveying: Enables 24-hour unmanned operation with high conveying efficiency.

Flexible Adaptability: Can be integrated with mixers, packaging machines, reactors, and other equipment to create automated production lines.

Intelligent Control: Utilizing PLC and touchscreen control, the conveying volume, time, and frequency can be set, and data logging and remote monitoring are supported.

Multiple Uses: The same machine can be adapted to different workstations by replacing the suction tube, improving utilization.

How does an Industrial Vacuum Loading Machine work?

An industrial vacuum loading machine uses pneumatic conveying technology. The operating process is divided into five stages: a vacuum pump or vacuum generator first creates negative pressure in the conveying pipe and silo. Then, under the influence of negative pressure, the material is drawn into the system through the suction tube. After entering the filtration and separation device, the material is trapped in the silo, and air is discharged through the filter. When the set conveying volume or time is reached, the vacuum system shuts down, the discharge valve at the bottom of the silo opens, and the material is discharged by gravity. Finally, the system resets and prepares for the next cycle.

What are the main components of an Industrial Vacuum Loading Machine?

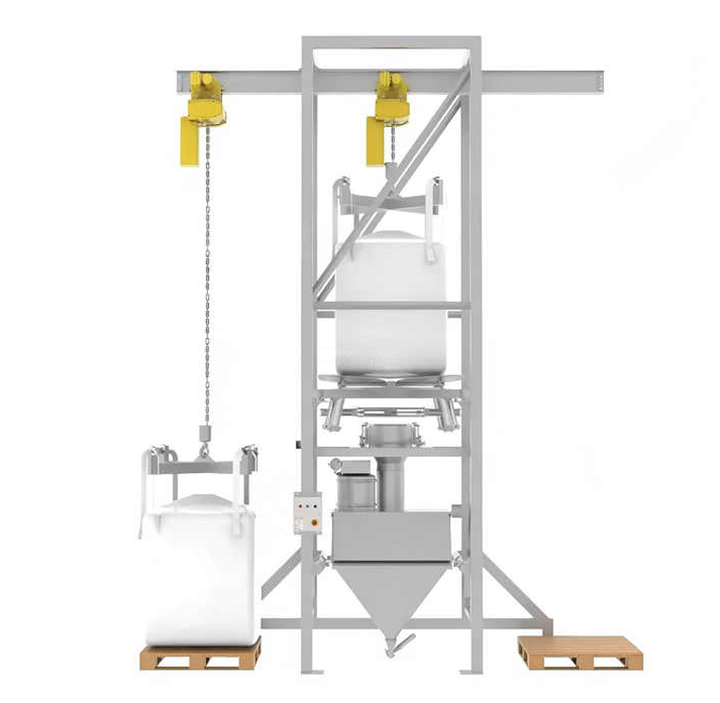

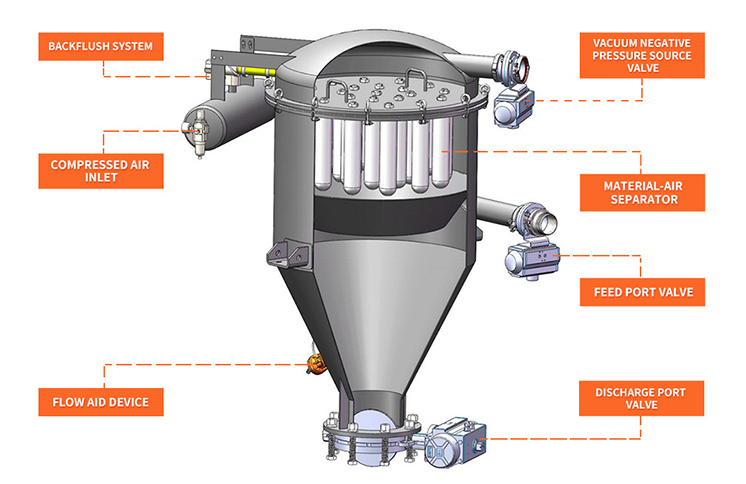

Industrial vacuum loaders primarily consist of modules such as a vacuum pump system, a filtration device, and conveying piping. These components work together to ensure dust-free and rapid conveying of powders and granular materials, meeting the stringent production requirements of industries such as pharmaceuticals and chemicals.

The vacuum source system includes :a vacuum pump, a vacuum generator, and a vacuum buffer tank. The vacuum pump provides continuous negative pressure, the vacuum generator is suitable for pneumatic applications, and the buffer tank stabilizes vacuum pressure.

The material conveying system consists :of a suction pipe, a wear-resistant conveying pipe, and a silo with an observation window. The suction pipe connects to the material inlet, the conveying pipe ensures stable long-distance material transportation, and the silo provides temporary material storage.

The filtration system: is equipped with a main filter, a safety filter, and a backflush cleaning device. The main filter intercepts material from entering the vacuum system, the safety filter provides dual protection, and the backflush device regularly cleans the filter element.

The control system :is centered around a PLC controller, equipped with a human-machine interface and various sensors. The PLC implements automated logic control, and the sensors provide real-time feedback on material level, pressure, and other data.

The auxiliary system includes :a discharge device, a support and moving device, and explosion-proof components. The discharge device controls material discharge, while the bracket and movable device enhance equipment installation flexibility.

Technical Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

What industrial materials can be conveyed by the industrial vacuum loader?

Designed specifically for powder and granular materials, the industrial vacuum loader can quickly convey materials such as plastic granules, powders, and slurries. Its closed conveying system ensures dust-free and pollution-free operation, making it an ideal choice for modern production!

Powder materials: These materials are used in a wide range of industries. In the pharmaceutical industry, these materials include APIs, excipients such as lactose, and traditional Chinese medicine powders and tablet granules; in the food industry, these materials include flour, milk powder, and starch; in the chemical industry, these materials include pigments and titanium dioxide; and in new energy materials, such as lithium battery cathode and cathode materials and photovoltaic silicon powder. All these materials require a conveying solution with excellent anti-sticking and filtration properties.

Granular materials: Primarily used in industries such as plastics, rubber, feed, and building materials, these materials require guaranteed particle integrity during conveying to minimize breakage and wear. Specialty Materials: These include graphite powder and metal powders that are prone to dust generation, hygroscopic chemical raw materials requiring dryness and protection, explosive and flammable materials requiring explosion-proof design, and high-value pharmaceutical intermediates and precious metal powders.

Industrial Vacuum Loading Machine Customer Case Studies

We serve clients from various industries, and we customize production solutions based on their on-site needs. Our equipment, with its sealed design and intelligent control as its core, significantly improves efficiency and enhances the working environment.

Flour Conveying for a Food Company: With a daily production of over 50 tons of various baked goods, this company handles a large amount of flour daily. A food-grade 316L stainless steel vacuum loader is used, with fully enclosed pipelines to effectively prevent flour from coming into contact with the outside world. A PLC intelligent control system allows for precise control of the delivery volume for each batch.

Dust-free Conveying of APIs in a Pharmaceutical Factory: The production process requires extremely high cleanliness and precision in material handling. The industrial vacuum loader, equipped with a high-precision cartridge filter with a filtration accuracy of up to 0.1μm, effectively intercepts minute dust particles and prevents material contamination.

Chemical companies :need to transport highly corrosive materials such as ammonium sulfate and nitric acid. Conventional conveying equipment previously used was unable to withstand the corrosion of the materials. Industrial vacuum loaders have solved this problem for this company. All parts of the equipment that come into contact with the material are made of corrosion-resistant materials. The fully enclosed conveying piping and specialized sealing design effectively prevent material leakage.

What is the price of an Industrial Vacuum Loading Machine?

The price of an industrial vacuum loaders is influenced by multiple factors, including conveying capacity, material configuration, and functional requirements. Basic models are suitable for general conditions, while customized models such as explosion-proof and sterile models require higher technical requirements and are therefore more expensive. Key factors include the choice of stainless steel or carbon steel, as well as additional features such as dust removal and automation. We offer cost-effective solutions and can customize the optimal configuration to meet your specific needs. Please contact us for a personalized quote.

The industrial vacuum loader redefines the standard for heavy industry material transportation with its "hardcore performance + scenario adaptation". It not only solves the efficiency and environmental shortcomings of traditional methods, but also provides core support for the safe and stable operation of industrial production lines through automation and intelligent design, becoming an indispensable key equipment in the upgrading and transformation of heavy industry.