Negative Pressure Vacuum Loader

Negative Pressure Vacuum Loader (NPVL) utilizes negative pressure airflow to automatically convey powders and granular materials. The negative pressure generated by a vacuum pump transports materials from the raw material silo to the target equipment through a sealed pipeline.

Belt Material: Stainless Steel

Voltage: 380V / Customizable

Application: Product Conveying

Frame Material: 304, 316 Stainless Steel/Carbon Steel

Conveying Capacity: 10 kg - 10 tons/hour

Length: Customizable, 1-100 meters

Conveyed Materials:Granular and Powdered Products

Applicable Industries: Provides high-standard stainless steel vacuum loading solutions for the food, pharmaceutical, and chemical industries.

What is a Negative Pressure Vacuum Loader?

Negative Pressure Vacuum Loader uses a sealed pipeline to cleanly transfer materials such as powders and granules. It can vacuum materials from the raw material silo to target equipment such as mixers and packaging machines, ensuring a dust-free and leak-free process. The device is fully sealed, dust-proof, and cross-contamination-resistant. Customizable with explosion-proof, sterile, and anti-static features, it can be adapted to accommodate different conveying volumes and distances, improving conveying efficiency while meeting industry compliance standards.

The Negative Pressure Vacuum Loader utilizes vacuum suction to achieve sealed material conveying. Customizable materials include corrosion-resistant stainless steel or high-strength carbon steel. The discharge port specifications and conveying pipeline layout can be flexibly adjusted to meet customer process requirements, precisely matching the material conveying requirements of different scenarios and helping companies improve production efficiency and product quality.

What are the advantages of the Negative Pressure Vacuum Loader?

The Negative Pressure Vacuum Loader utilizes negative pressure suction as its power source. Its fully enclosed structure eliminates dust leakage and cross-contamination, allowing it to transport materials such as powders and granules. Customizable options include explosion-proof and aseptic design, making it suitable for a wide range of industries.

Clean and pollution-free: The fully enclosed conveying structure eliminates dust and prevents contact between materials and air, protecting them from moisture and contamination while safeguarding the health of operators.

Widely adaptable: It can transport a variety of materials, including powders, granules, and microspheres. Customizable materials and features make it suitable for industries such as food, pharmaceuticals, chemicals, and electronics.

Highly customizable: It supports full customization, offering explosion-proof, aseptic, high-temperature-resistant, and anti-static options. Parameters include flexible adjustments for conveying capacity, distance, and vacuum level.

Modular design: The equipment features both split and integrated modular designs. The split design separates the vacuum pump from the main unit to minimize vibration and noise impacts on materials. The integrated design occupies less than 1.5 square meters and offers plug-and-play functionality, enabling quick adaptation to food production line changeovers.

Material Diversity: A variety of materials are available based on the application scenario: 304 stainless steel is cost-effective and resistant to weak acids and alkalis; 316L stainless steel is chloride-resistant and certified as sterile, making it suitable for pharmaceutical and highly corrosive environments; carbon steel is economical, durable, and wear-resistant, making it suitable for the building materials and feed industries.

Negative Pressure Vacuum Loader Technical Specifications

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Negative Pressure Vacuum Loader Technical Principle

The core principle of the Negative Pressure Vacuum Loader is to create a negative pressure environment within a closed pipeline using a vacuum pump or vacuum generator. The material is then drawn from the storage silo into the pipeline using the pressure difference from atmospheric pressure and then transported to the target location.

Negative Pressure Generation: Once the vacuum pump is activated, it rapidly draws air from the pipeline, creating a vacuum environment below the ambient pressure.

Material Intake: Under negative pressure, material enters the pipeline through a suction gun or vibrating feeder. For materials prone to agglomeration, the equipment can be equipped with a special vibrator to assist in material discharge, ensuring smooth conveying.

Gas-Solid Separation: After the material enters the separation container with the airflow, a cyclone separator intercepts over 99% of fine powder, preventing it from entering the filter.

Backflush Cleaning: After conveying, compressed air flows through a pulse valve to reverse-purge the filter element, removing adhering dust.

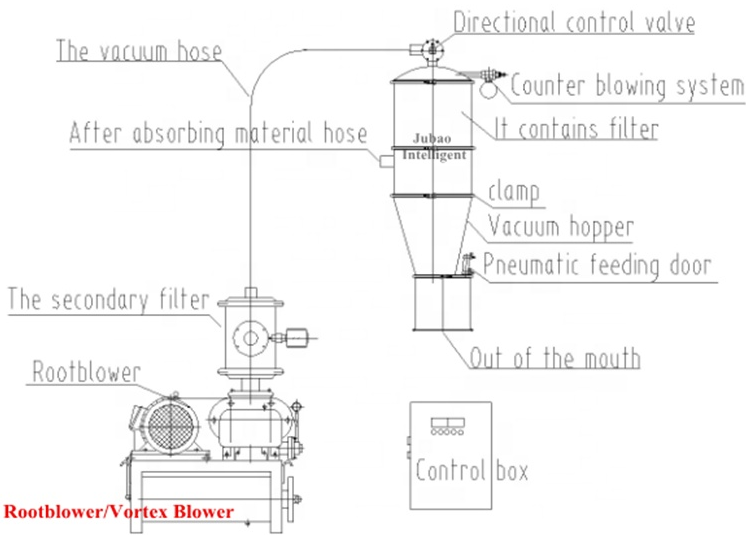

Main Structure of the Negative Pressure Vacuum Loader

The Negative Pressure Vacuum Loader is designed around four key functions: negative pressure generation - material conveying - gas-material separation - and discharge control. Each component works together to ensure stable operation.

Negative Pressure Generator: Serving as the power source, this device is commonly a rotary vane vacuum pump, Roots vacuum pump, or oil-free vacuum pump. Depending on industry requirements, it can be equipped with an explosion-proof motor to ensure safe operation in flammable and explosive environments.

Suction and Conveying Components: This includes the suction port and conveying piping. The pipe diameter is tailored to the conveying volume and material particle size.

Air-Material Separation System: Consists of a separation hopper and a high-precision filter. The filter has an interception rate of over 99.99% and can filter fine dust particles larger than 0.1μm. Some units are equipped with an automatic backflush function to prevent filter clogging.

Discharging and Control System: The discharge valve ensures a tight seal during discharge, preventing dust leakage. The PLC control system with a touch screen allows for automatic cyclic operation, including material intake, full-load shutdown, and unloading restart.

What types of materials can the Negative Pressure Vacuum Loader mix?

The Negative Pressure Vacuum Loader can convey powders, granules, and powder-granule mixtures, such as premixed feed, seasonings, and chemical catalysts. This prevents pre-mixing material separation and lays the foundation for subsequent uniform mixing.

Powder Material Applications: The Negative Pressure Vacuum Loader can quickly convey powder materials of varying fineness. Fine powders include common materials such as flour, milk powder, pharmaceutical powders, and toner. It meets the basic conveying needs of industries such as food, pharmaceuticals, and office supplies.

Granular Material Applications: For granular materials, the equipment can precisely adapt to particle size differences. For small particles such as plastic granules, food additives, and pills, the smooth conveying pipe and adaptable discharge valve prevent particle breakage, making it suitable for the plastics processing, food, and pharmaceutical industries.

Mixed Material Applications: For powder-particle mixtures such as premixed feed, seasonings, and chemical catalysts, the negative pressure vacuum loader, with its optimized gas-material separation system and auxiliary mixing design, prevents stratification and ensures uniform conveying of the mixed material.

Negative Pressure Vacuum Loader Custom Manufacturing Case Studies

We have multiple custom manufacturing cases, ranging from aseptic conveying in pharmaceuticals, oxygen-free transfer of lithium batteries, to dust control in food. The Negative Pressure Vacuum Loader can be customized with materials, functions, and parameters to meet the needs of various industries.

Pharmaceutical Companies: Biopharmaceutical companies need to transfer active antibiotic raw materials from isolators to filling machines. The core challenge is to ensure complete sterility and zero cross-contamination. The solution was a customized 316L stainless steel sterile negative pressure loader with an integrated HEPA filter with a 99.99% interception efficiency, a sterilization port, an air pressure equalization valve, and an anti-static design to prevent material adsorption.

Lithium battery material factories: Transporting easily oxidized high-nickel cathode materials faces the pain points of maintaining an oxygen content below 0.5% and the risk of dust explosions. The solution was an explosion-proof negative pressure loader with a full nitrogen protection system, a titanium alloy suction tube resistant to NMP solvent corrosion, and an anti-static sintered metal filter.

Food factories: Dairy companies faced the pain points of dust pollution from manual milk powder feeding and the difficulty of integrating with automated packaging lines. The solution was a 304 stainless steel food-grade loader with an integrated pulse dust removal system to reduce dust concentration from 10mg/m³ to 0.8mg/m³. The loader was linked to the packaging machine via PLC control.

How to choose the right negative pressure vacuum loader for your application?

When selecting a negative pressure vacuum loader, you need to consider material properties, production requirements, and application compliance.

Material properties: Determine the equipment material and negative pressure parameters based on the material's form, particle size, specific gravity, and corrosiveness.

Production requirements: Select equipment specifications based on hourly delivery volume and delivery distance. Multi-station delivery requires a reversing valve and multi-point control system.

Compliance requirements: For the food/pharmaceutical industry, select FDA-certified materials and CIP cleaning capabilities. For explosion-proof applications, select Ex-certified motors and anti-static piping.

What factors influence the price of a negative pressure vacuum loader?

The price of a negative pressure vacuum loader is influenced by many factors, including material selection (such as 304/316L stainless steel), explosion-proof/aseptic features, and technical specifications (such as delivery volume and distance).

Material selection: Different materials vary in cost, performance, and processing difficulty, resulting in significant price differences. For example, stainless steel negative pressure vacuum loaders offer a high cost-effectiveness; carbon steel models are economical and durable, suitable for the building materials and feed industries. Small models may cost between 1,500 and 3,000 yuan.

Functional Configuration: Negative pressure vacuum loaders with special features, such as explosion-proof and aseptic models, are more expensive. These models, because they must meet specific safety and hygiene standards, require additional costs for design, manufacturing, and certification. Furthermore, the configuration of the intelligent control system also affects the price; basic relay-controlled models are relatively affordable.

Technical Parameters: Higher technical parameters such as conveying capacity, conveying distance, and vacuum level require higher specifications and performance requirements, and the price will also increase accordingly.

Structural Design: Split-type negative pressure vacuum loaders, with the vacuum pump separated from the main unit, are suitable for long-distance conveying, but are relatively expensive. Integrated designs, with a smaller footprint and plug-and-play functionality, may be more affordable.

Frequently Asked Questions

Differences between Negative Pressure Vacuum Loaders and Vacuum Loaders

Negative pressure vacuum loaders are the core type of vacuum loaders. Vacuum loaders are a general term for equipment that utilizes a vacuum environment to convey materials. Based on the vacuum generation method, they can be categorized as either negative pressure or positive pressure. Negative pressure vacuum loaders specifically draw air from the system to create a negative pressure, using the air pressure differential to draw materials in. They focus more on "negative pressure suction" and are suitable for dust-free, low-pollution applications, such as the food and pharmaceutical industries.

What are the advantages of negative pressure vacuum loaders over other types of vacuum loaders?

Compared to other types of vacuum loaders, negative pressure vacuum loaders offer key advantages in cleanliness, safety, and adaptability. They utilize negative pressure to draw materials in, creating a fully enclosed system that prevents dust from escaping, meeting the dust-free and cross-contamination requirements of industries like food and pharmaceuticals. The negative pressure environment also reduces the likelihood of material agglomeration or stratification, making them suitable for sensitive materials such as fine and ultrafine powders.

Working Principle of the Negative Pressure Vacuum Loader

The Negative Pressure Vacuum Loader utilizes the core principle of "negative pressure adsorption." A vacuum pump extracts air from a closed conveying system, creating a stable negative pressure environment. This creates a pressure differential between the external atmospheric pressure and the negative pressure within the system. This pressure differential draws the material through the suction port and into a dedicated conveying pipeline. The air-material mixture then enters a separation hopper, where it is separated by a filter and other components. The material falls by gravity into the target equipment, and the filtered, clean air is exhausted from the system.

The Negative Pressure Vacuum Loader is not only an innovator in industrial conveying efficiency, but also a practitioner of smart manufacturing and green production. From transporting trace samples in the laboratory to continuous operation on 10,000-ton production lines, its technological iterations have consistently revolved around the core requirements of "speed, cleanliness, and safety."