Solid Liquid Separation Equipment

Used for liquid and solid mixture to achieve solid-liquid separation

Filtration accuracy: 5 microns

Processing capacity: 1-5 tons/hour

Material: pear juice, ceramic glaze, slurry, fruit juice, soy milk, etc.

What is Solid Liquid Separation Equipment?

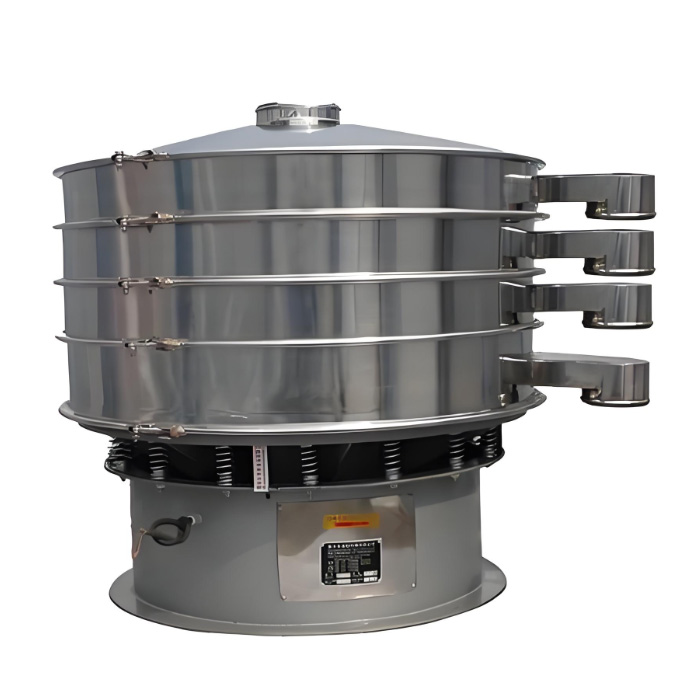

Solid Liquid Separation Equipment is mainly used to separate solid particles from liquid in mixed materials. It uses the three-dimensional vibration generated by the vibration motor to quickly layer the material on the screen, achieve efficient solid-liquid separation, and automatically discharge impurities. The filtration accuracy can reach 25 microns (500 meshes), and the processing flow rate is up to 5 tons/h. The equipment is mostly made of 304/316 stainless steel, which has strong corrosion resistance and is suitable for humid or acid-base environments to ensure long-term stable operation.

What are the functions of Solid Liquid Separation Equipment?

The functions of Solid Liquid Separation Equipment are mainly to separate solid and liquid through solid-liquid mixtures, graded filtration and dehydration and impurity removal, as follows:

Solid-liquid separation: remove impurities in liquid (such as suspended matter in sewage, particulate foreign matter in beverages), such as drug residues in liquid medicine, and pulp fibers in juice.

Graded filtration: grade the solid components in the liquid according to particle size (such as fineness control of coatings and inks).

Dehydration/removal of impurities: Concentrate liquids containing a small amount of solids (such as chemical slurries, food processing waste liquid treatment)

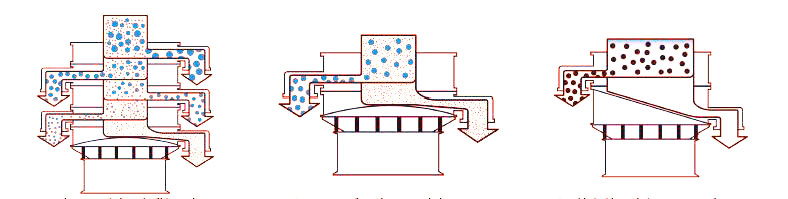

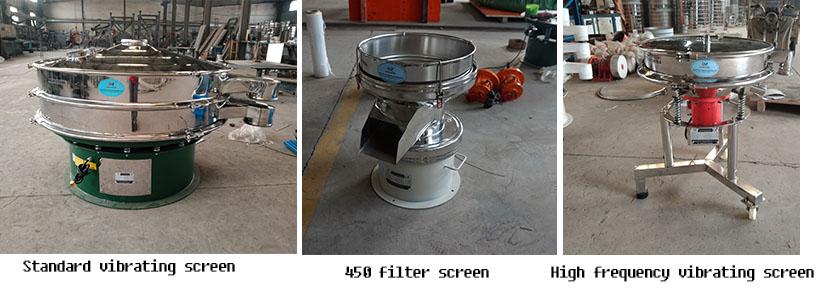

What types of Solid Liquid Separation Equipment are there?

Solid Liquid Separation Equipment can be divided into three types: standard vibrating screen, 450 filter screen, and high-frequency vibrating screen. They can be selected according to the needs of different industries and the characteristics of solid-liquid mixed materials.

Standard rotary vibrating screen: general solid-liquid separation, such as soy milk filtration in the food industry, coating screening in the chemical industry, multi-layer screen (1-5 layers), high precision (500 mesh), 304 stainless steel material corrosion resistance

450 filter screen: single-layer design, suitable for low-viscosity liquids, often used for small flow, high-precision filtration, such as pharmaceutical intermediates, biological preparations, fast screen replacement, only 3-5 minutes.

High-frequency vibrating screen: 3000 high-frequency vibrations per minute + bouncing ball cleaning to prevent clogging of the screen holes, suitable for high-viscosity liquids (such as paint, glue) or materials that are easy to clog the screen.

What are the advantages of Solid Liquid Separation Equipment?

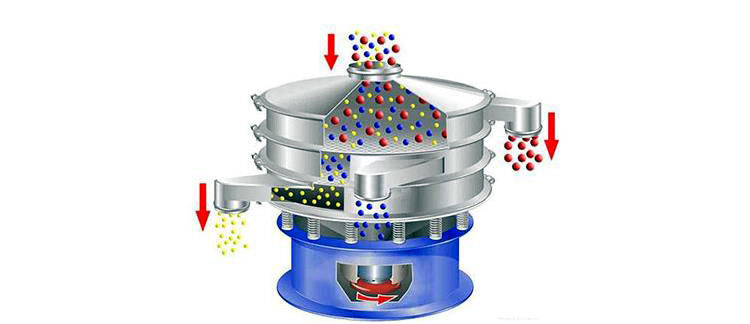

Solid Liquid Separation Equipment uses the principle of three-dimensional vibration to drive the material to form a spiral progressive motion on the screen surface to achieve efficient separation - liquid quickly passes through the screen, and solids are automatically discharged to the edge. The processing capacity can reach 5 tons/hour, which is more than 3 times more efficient than traditional methods. Its patented mother-child net structure only takes 3-5 minutes to replace the screen, saving 70% of maintenance time. At the same time, the innovative bouncing ball design avoids direct impact on the working net, significantly extending the life of the screen by more than 2 times. The equipment has strong adaptability and can efficiently process low-viscosity juice, industrial wastewater, high-viscosity coatings, and Chinese medicine extracts. It is also equipped with an adjustable gate control system to accurately adjust the material flow rate to adapt to materials with different characteristics.

To ensure long-term stable operation, Solid Liquid Separation Equipment is equipped with a multi-stage net cleaning device (rubber ball or ultrasonic wave optional) to effectively prevent net blockage, and even easily agglomerated nanomaterials or viscous Chinese medicine powders can maintain stable screening. In terms of materials, the part in contact with the material is made of SUS304 stainless steel, and the rubber accessories are made of food-grade silicone, which fully meets the strict requirements of the food, pharmaceutical and other industries for hygiene and corrosion resistance, and is an ideal choice for modern solid-liquid separation processes.

What is the working principle of Solid Liquid Separation Equipment?

Solid Liquid Separation Equipment mainly uses the principle of vibration to achieve the separation of solids and liquids. During the working process, the screen vibrates at high frequency to cause the liquid material to produce a throwing motion on the screen surface, thereby achieving a screening effect. When the liquid and solid mixture enters the vibrating screen, the solid particles are vibrated, jumping and rolling on the screen surface, while the liquid flows out through the screen, thereby achieving solid-liquid separation.

Advantages compared to traditional filtration methods

| Traditional filtration | Solid Liquid Separation Equipment |

| Manual operation, low efficiency | Fully automatic, 120m³/h high flow |

| Easy to block the net, need frequent cleaning | Self-cleaning net design, 3-5 minutes net change |

| Unstable accuracy | Stable screening to 500 mesh |

What are the applications of Solid Liquid Separation Equipment?

Solid Liquid Separation Equipment is suitable for filtering a variety of liquid materials, including low-viscosity liquids (such as juice, beverages, industrial wastewater, cleaning fluids) and high-viscosity materials (such as coatings, inks, Chinese medicine extracts, syrups). In the food industry, it is used for juice clarification and yeast separation; in the pharmaceutical field, it is used to process Chinese medicine liquids and fermentation liquids; in the chemical industry, it is used to separate pigments and resins; and in environmental protection projects, it is used to process sludge and wastewater. Its efficient screening capabilities can also be used in mining (slurry dehydration) and ceramics (glaze filtration) and other scenarios. By adjusting the mesh size (20-500 mesh), it can accurately match the separation requirements of different particle sizes and meet the strict requirements of various industries for solid-liquid separation.

Sieve For Polystyrene Pellets

Sieve For Polystyrene Pellets Foam Screening Machine

Foam Screening Machine