Granule stick packaging machine

Granule stick packaging machines are used to package loose granular products such as sugar, salt, small grains, seeds, and spices. Common models include vertical and multi-lane granular stick packaging machines. Prices range from$1,000 to $15,000. Packaging speed: 10-60 bags/minute Bag size: 50-150mm in length, 30-80mm in width Applicable film materials: Composite film, aluminum-plastic film, etc. Dimensions: Approximately 1800 x 800 x 1600mm Control method: PLC + touch screen

What is a granule stick packaging machine?

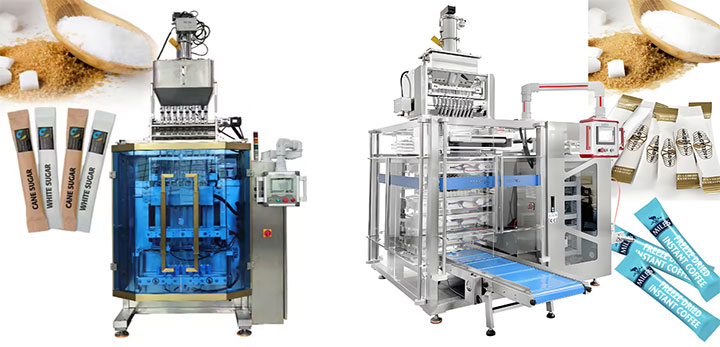

Granule stick packaging machine are often used for packaging granular materials that require portability and single-serving consumption. There are two common types of packaging machines: vertical granule stick packaging machines that package one bag at a time, and multi-row granule stick packaging machines with four, six, eight, or 12 rows.

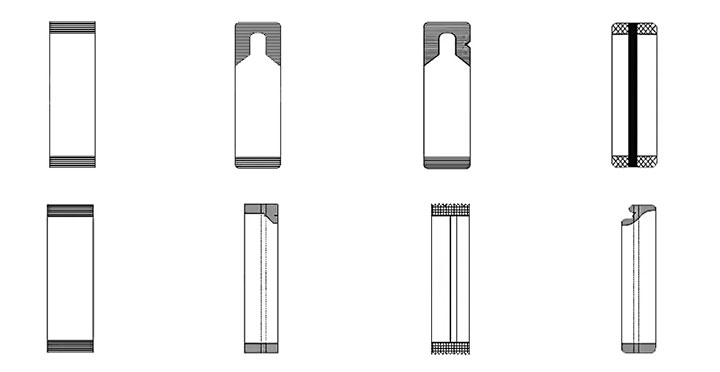

The granule stick packaging machine boasts a volumetric measurement accuracy of up to ±3%, and a high-precision weighing system ensures a packaging error of ≤±1g. Packaging typically ranges from 1g to 50kg, with bag widths ranging from 12-150mm and lengths from 30-320mm. Single-lane packaging machines can produce 30-60 bags per minute, while multi-lane packaging machines can reach up to 300 bags per minute. Heat-sealable films such as PA/PE, PET/PE, and aluminum are commonly used for packaging. Bag types primarily include back-seal stick bags, and cutting methods include flat cutting and serrated cutting. Vertical granule stick packaging machines typically cost between US$500 and US$4,500, while multi-lane granule stick packaging machines range from US$12,000 to US$50,000.

Granule Stick Packaging Machine Bag Types

Two Granule Stick Packaging Machine Types

The vertical Granule Stick Packaging Machine is suitable for medium-flowing, non-agglomerated granules, such as instant coffee powder and dry grains. Its single-channel feeding system ensures stable packaging. It is suitable for small to medium-sized batches, with a capacity of 1,000-5,000 bags per hour. It is commonly used in small food factories, specialty workshops, and small-batch customization, or for laboratory sample packaging. It offers easy and time-saving adjustments to packaging specifications, occupies minimal floor space, and has a moderate metering accuracy requirement of within ±2%. Its procurement, installation, and maintenance costs are low, making it suitable for the budgets of small and medium-sized businesses.

The multi-lane Granule Stick Packaging Machine offers greater material adaptability and can handle fine particles, slightly adhered materials, and materials containing trace impurities (such as oil-containing nut shreds and fibrous grains). Its multiple independent feeding channels and anti-clogging mechanism reduce clogging. Its core advantage is high efficiency, with a capacity of 8,000-30,000 bags per hour, making it suitable for large-scale, standardized production in the food and pharmaceutical industries. While it supports multiple specifications, it requires multi-channel simultaneous calibration, which is time-consuming and more suitable for stable production of a single or limited number of specifications. It also occupies a large space, requires high metering accuracy, and has high procurement, installation (it requires a conveyor dust removal system), and maintenance costs. It is therefore suitable for companies with sufficient budgets and large-scale production.

Granule stick packaging machine parameters

| Model |

SF320 |

SF620 |

SF720 |

SF820 |

| Track numble | 4-8 track | 4-12 track | 4-12 track | 4-12 track |

| Filling method | volumetric cup filling | |||

| Capacity | 30-45 cycle/min | |||

| Stick size |

L:50-180mm W:17-35mm |

L:50-180mm W:17-65mm |

L:50-180mm W:35-70mm |

L:50-180mm W:35-70mm |

| Film roll size | Max 360mm | Max 650mm | Max 750mm | Max 850mm |

| Sealing type | Back sealing/stick bag/irregular shape | |||

| Power |

3.5KW |

4.5KW |

5.5KW | 6.5KW |

| Air Comsuption |

0.8MPA0.8m³ |

0.8MPA0.8m³ |

0.8MPA0.8m³ |

0.8MPA0.8m³ |

Granule stick packaging machine price (reference)

Small manual or semi-automatic models, due to their low level of automation and limited functionality, typically cost between US$500 and US$2100. These machines are slow, capable of only a few bags per minute, and often require manual assistance, making them suitable for small-batch production. Fully automatic granule stick packaging machines cost approximately US$2,500 to US$4,500, can pack 18 to 55 bags per minute, and can automatically complete basic processes such as bag making, metering, unloading, sealing, and slitting. Multi-channel, high-speed, or specialized packaging machines cost between US$18,000 and US$35,000. Models with 12 channels, for example, can achieve packaging speeds of up to 720 packages per minute. They also feature features such as automatic batch number printing, precise photoelectric eye tracking, and custom-shaped sealing, making them suitable for large-scale production.

Benefits of Granule Stick Packaging Machines for Packing Granular Materials

Granule stick packaging machines can control the granule filling amount to within ±0.5g, eliminating uneven portioning caused by manual operation and ensuring consistent product specifications. They are suitable for applications such as food and pharmaceuticals where dosage requirements are stringent. A single machine can package hundreds to thousands of packages per hour, far exceeding manual speeds. It can operate continuously, reducing time lost during shift changes and breaks, and shortening production cycles. The packaging process is sealed to isolate moisture, oxygen, and dust, delaying granule clumping and oxidation, extending shelf life, preventing contamination during transportation and storage, and maintaining stable product quality. Reducing manual labor eliminates the need for large numbers of people responsible for weighing, bagging, and sealing, reducing labor costs, minimizing material waste associated with manual operations, and improving production efficiency.

What granular materials can the Granule Stick Packaging Machine package?

The Granule Stick Packaging Machine can package materials including coffee powder, soy milk powder, chopped nuts, chocolate chips, white sugar, pepper, isatis root granules, probiotic granules, donkey-hide gelatin granules, calcium supplement granules, laundry detergent granules, bath salt granules, laundry gelatin core granules, trace element fertilizer granules, and pet snack granules. The equipment is suitable for materials that generally require moderate particle size, good fluidity, and are non-corrosive.