Powder stick packaging machine

Powder stick packaging machines are available in a variety of bag types, including three-side seal and four-side seal models, with prices ranging from $2,000 to $7,000. Packaging speed: 30-60 bags/minute Measuring range: 5-50 ml/bag Measuring accuracy: ±1% or less Contact material: 304 stainless steel Device dimensions: 1200 x 800 x 1800 mm

What is a powder stick packaging machine?

Powder stick packaging machine are suitable for packaging various powders with good flowability, high moisture absorption, or strong adhesion, such as coffee powder, protein powder, fruit and vegetable powder, milk powder, traditional Chinese medicine powder, and pigment powder.

The packaging capacity ranges from 1 to 30 grams. Single-lane or multi-lane powder stick packaging machines are available, depending on production requirements. Single-lane powder stick packaging machines complete one stick pack per cycle, typically with a capacity of 20-50 packs per minute. They are suitable for small to medium-sized batches and are priced between $2,000 and $7,000. Multi-lane powder stick packaging machines are commonly available in 2-, 4-, 6-, and 8-lane configurations. They can simultaneously complete multiple stick packs per cycle, with a capacity of 100-300 packs per minute. Prices typically range from $8,000 to $20,000.

Powder stick packaging machine equipment types

Two models are available, depending on production capacity requirements: single-lane powder stick packaging machines and multi-lane powder stick packaging machines. Depending on the powder's characteristics, you can choose between screw and vibrating feeders. Screw feeders offer high precision and are less prone to clogging, while vibrating feeders reduce residual material.

Single-lane powder stick packaging machines automatically complete a series of operations, including loading, metering, bagging, filling, sealing, coding, and finished product output. Utilizing high-precision servo film drawing, PLC control, human-machine interface, photoelectric tracking, and constant temperature control, this machine is easy to operate. By replacing certain modules, it can package a variety of materials, including granules, pills, powders, and liquids. The packaging speed typically ranges from 30 to 40 bags per minute, requiring relatively minimal space.

Multi-lane powder stick packaging machine: This machine typically consists of 2 to 12 rows of units and can produce multiple stick packs simultaneously. It utilizes servo drive control technology and a high-resolution human-machine interface. PLC-controlled, this machine offers stable operation and features automatic counting and fault alarms. Filling utilizes precision piston cylinders or screws, achieving an accuracy of ±0.5%. Capacity ranges from 100 to 450 bags per minute, but due to its size, it requires a larger space.

Powder Stick Packaging Machine Technical Parameters

| Model |

SF320 |

SF620 |

SF720 |

SF820 |

| Track numble | 4-8 track | 4-12 track | 4-12 track | 4-12 track |

| Filling method | volumetric cup filling | |||

| Capacity | 30-45 cycle/min | |||

| Stick size |

L:50-180mm W:17-35mm |

L:50-180mm W:17-65mm |

L:50-180mm W:35-70mm |

L:50-180mm W:35-70mm |

| Film roll size | Max 360mm | Max 650mm | Max 750mm | Max 850mm |

| Sealing type | Back sealing/stick bag/irregular shape | |||

| Power |

3.5KW |

4.5KW |

5.5KW | 6.5KW |

| Air Comsuption |

0.8MPA0.8m³ |

0.8MPA0.8m³ |

0.8MPA0.8m³ |

0.8MPA0.8m³ |

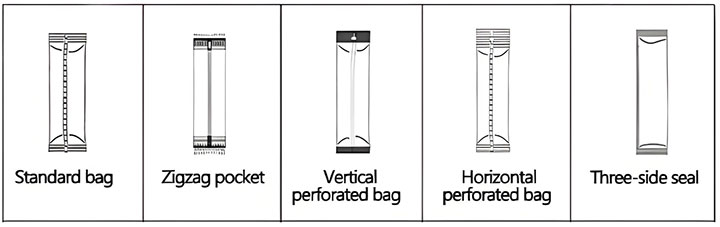

Powder Stick Packaging Machine Bag Types

Bag Types: Includes three-side seal bags, four-side seal bags, back-seal bags, stick bags, linked bags, bags with hanging holes, and custom-shaped bags.

Bag Material: Composite film bags are the core choice. PET/PE composite bags offer a cost-effective design and basic moisture resistance, making them suitable for general powders. Aluminum-plastic composite bags, with their aluminum foil layer, provide both light and oxygen protection, making them suitable for powders like probiotics and vitamin powders. PET/AL/PE three-layer composite bags offer enhanced barrier properties and are suitable for high-end powders such as collagen powder and meal replacement powders that are sensitive to temperature, humidity, and oxygen.

Packaging Process Selection: If light and oxygen protection are required, equipment compatible with aluminum foil composite packaging is preferred, and the heat-sealing temperature must be precisely controlled (±1°C). If easy-tear notches or printing are required, confirm whether the equipment includes an easy-tear line lamination device and an online inkjet/laser coding module (supporting printing of information such as production date and batch number).

Powder Stick Packaging Machine Structure

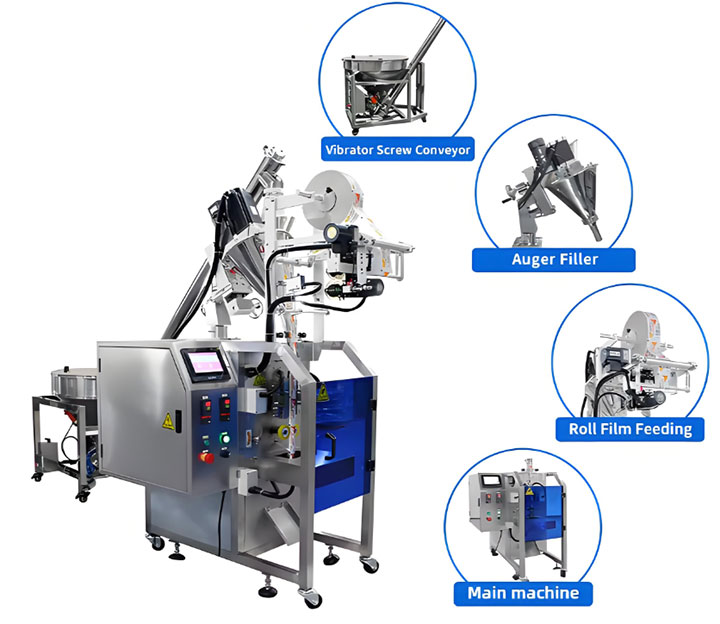

Single-lane Powder Stick Packaging Machine Structure: The core components include a vibrating screw conveyor, which uses vibration and screw drive to evenly convey powder material to the next stage, preventing blockages. The screw filler ensures consistent powder weight in each bag through precise screw rotation. The film feeder smoothly conveys the packaging film in preparation for bag making. The main machine serves as the control center, integrating the operations of various components and coordinating the entire process: bag making, filling, sealing, and cutting.

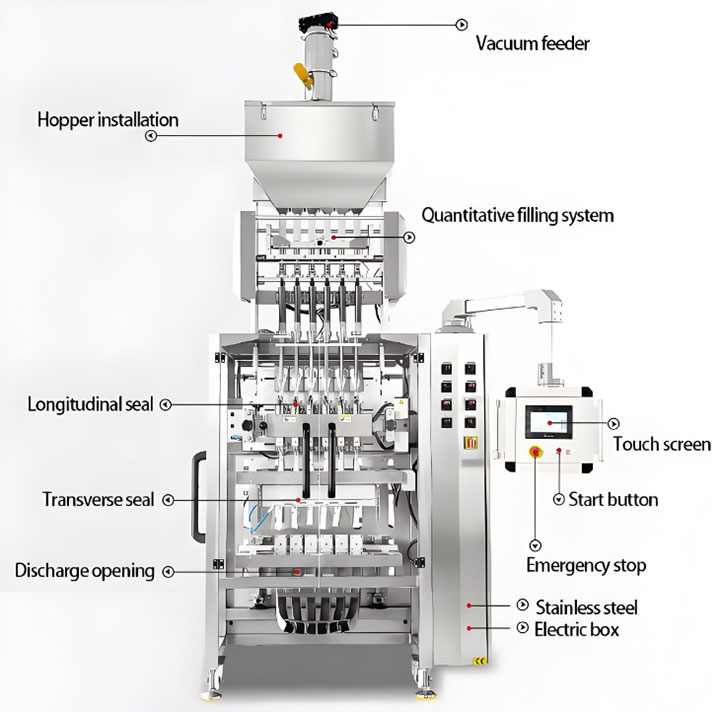

Multi-lane Powder Stick Packaging Machine Structure: A vacuum loader conveys material to the hopper, a quantitative filling system precisely controls the material volume, and longitudinal and transverse sealing devices sequentially seal the bags longitudinally and transversely. The packaged products are then discharged through the discharge port. The machine is also equipped with control components such as a touch screen, start and emergency stop buttons, and a stainless steel electrical box ensures the stability of the electrical system. These components work together to achieve multi-lane powder packaging.

Powder stick packaging machine applications

In the food industry, the powder stick packaging machine can package coffee powder, milk powder, soy powder, powdered sugar, seasoning powder, chocolate powder, and 3-in-1 mixed powders. In the pharmaceutical industry, it can be used to package medicinal powders, traditional Chinese medicine powders, Western medicine powders, and health supplement powders. In the daily chemical industry, it is suitable for cosmetic powders such as pressed powder and loose powders, as well as chemical powder raw materials such as pigments and additives. In the health supplement industry, it can also be used to package protein powder, probiotic powder, and nutritional supplement powders.

Powder Stick Packaging Machine Supplier

Our factory specializes in the manufacture of powder stick packaging machines and has 18 years of manufacturing experience. Customers can bring powder samples to our factory for machine trials to test filling accuracy and packaging seals. We also customize machine parameters based on the flowability and fineness of different powders, ensuring that packaging standards are met for various powders, including coffee powder, meal replacement powder, and condiments. Core components are constructed of highly wear-resistant materials, extending service life and reducing maintenance costs. Furthermore, our company provides comprehensive after-sales service, providing comprehensive support from installation and commissioning to ongoing operations and maintenance. Our reliable quality and attentive service have made us a trusted partner for numerous businesses.