Vacuum Granule Packaging Machine

The Vacuum Granule Packaging Machine can accommodate the following bag types: three-side seal bags, four-side seal bags, and stand-up pouches. The price is around US$3,000-20,000. Packaging Speed: 10-60 bags/minute Weighing Range: 1-500g Bag Specifications: Length 50-180mm, Width 30-120mm Vacuum Degree: ≤-0.092MPa

What is Vacuum Granule Packaging Machine?

Vacuum Granule Packaging Machine vacuum-packs granular materials to prevent moisture and effectively extend their shelf life. Common machine types include horizontal and vertical. The horizontal model is suitable for packaging meat and canned goods, while the vertical model is suitable for packaging flowing granules. The machine packs at a speed of 600 bags/hour. Packaging capacity depends on the bag type and machine configuration, typically ranging from 5-10kg.

The Vacuum Granule Packaging Machine can accommodate the following bag types: three-side seal bags, four-side seal bags, and stand-up pouches. Entry-level semi-automatic equipment costs approximately $3,000-8,000 USD and is suitable for small-scale production or start-ups. Mid- to high-end fully automatic equipment typically costs between $15,000 and $50,000 USD and can meet the needs of large-scale, high-capacity production.

Vacuum Granule Packaging Machine Workflow

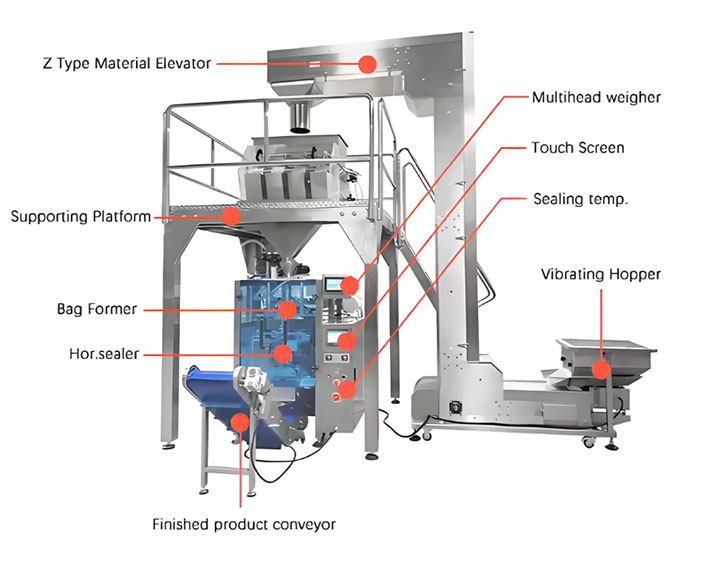

The Vacuum Granule Packaging Machine's workflow involves packaging in a series of stages. The loading stage involves feeding materials into the hopper via a conveyor belt or manually, with sensors monitoring the feed in real time to ensure stable material flow. The metering stage uses a screw, measuring cup, or electronic scale to precisely control the material according to a preset weight. The packaging film is formed into the desired bag shape by a former. After the material is filled, the bag enters the core vacuum stage, where air is removed to maintain freshness and prevent moisture. The sealing device then uses heat or pulse sealing to ensure a tight seal, and the cutting device finally cuts the bags into individual packages.The structure diagram of Vacuum Granule Packaging Machine is as follows:

What materials are suitable for the Vacuum Granule Packaging Machine?

The Vacuum Granule Packaging Machine is suitable for packaging granular materials such as nuts and grains for food, legumes and grains for agricultural products, chemical granules, and medicinal herbs. It can accommodate a variety of particle sizes. Fine powders such as coffee grounds require an anti-clogging feed structure to prevent leakage; large particles such as nuts and beans require ample feed channels and molds to prevent jamming; and medium-sized grains can be precisely metered.

Depending on the material properties, moisture-absorbing salts and sugars require Teflon anti-sticking material; corrosive chemical particles use 316 stainless steel to prevent reactivity; and pharmaceutical particle contact parts meet food-grade standards for hygiene.

Depending on fluidity, loose grains can be fed with a standard screw feeder, while sticky, wet grains require vibratory or pneumatic feeding. This ensures that materials with varying fluidities can be packaged and ensures continuous production.

Vacuum Granule Packaging Machine Parameters

| MODEL | ZT-500 | |

| Bag Type | vacuum & reseal brick bag | |

| Maximum Capacity | up to 2kg | |

| Minimum Capacity | depend on product characteristics but normal 100g | |

| Speed | 8-20bags/min (depend on products characteristics) | |

| Hopper Capacity | 50 Litres | |

| Weighing Accuracy | ± 0.2% depend on products characteristics | |

| Bag Length | 50 - 340mm | |

| Bag Width | 80 - 260mm | |

| Reel Film Width | ≤ 540mm | |

| Film Thickness | 0.04 - 0.12mm | |

| Reel Outer Dia. | 400mm | |

| Reel Inner Dia. | 75mm | |

| Voltage | AC220V/50Hz 1 phase or customer specification | |

| Machine | ZVF-260 | 3kw, 800kg, 1650*1140*1650mm |

| ZW-2000 | 1.2kw, 250kg, 1000*950*2200mm | |

| ZV-1000 | 5.5kw, 600kg, 3125*660*1050mm | |

| Compressed Air Requirement | 0.6MPa 0.36M3/min | |

Vacuum Granule Packaging Machine Features

The Vacuum Granule Packaging Machine has significant features. In terms of performance, the vacuum degree reaches 0.06-0.09MPa, meeting various freshness preservation and storage needs. The packaging speed is flexible, ranging from 30-60 bags/minute in semi-automatic mode and 100-200 bags/minute in fully automatic mode, adapting to the production capacity of different granular materials. Material-contacting parts are made of food-grade 304 stainless steel, which is anti-fouling, corrosion-resistant, and easy to clean. The frame is welded from thickened steel to ensure stable high-speed operation. In terms of intelligence, the machine is equipped with a touchscreen PLC control system, allowing intuitive parameter setting and supporting multiple recipe storage. Safety features such as an emergency stop button, protective cover, and overload protection ensure operational and equipment stability.

Vacuum Granule Packaging Machine Types

Common types of vacuum granule packaging machines are vertical and horizontal. Vertical vacuum granule packaging machines feature a vertical design, with material entering through an upper hopper and bags remaining upright during the packaging process. They occupy a relatively small area and are suitable for production workshops with limited space. Its advantages lie in its ability to achieve fully automatic continuous packaging, high packaging efficiency, and reduced spillage. It is commonly used for packaging small and medium-sized granules in industries such as food and agricultural products. A horizontal vacuum granule packaging machine utilizes a horizontal structure, with vacuuming and sealing the bags horizontally. Its larger vacuum chamber makes it suitable for packaging larger or irregularly shaped granules, such as large bags of fertilizer granules and plastic granules.

Price of Vacuum Granule Packaging Machine

Entry-level/economical semi-automatic vacuum granule packaging machines range from $3,000 to $8,000. These machines typically have a single or dual chamber, with manual bag placement and removal, while the machine performs vacuuming and sealing. These machines have lower production capacity and are suitable for startups, small-scale production, or laboratory use. Standard fully automatic machines range from $15,000 to $50,000. These industrial-grade machines fully automatically complete bag making, metering and filling, vacuuming, sealing, date printing, and finished product output. They offer high production capacity (up to dozens of bags per minute) and excellent stability.

Vacuum Granule Packaging Machine Packaging Requirements

Vacuum Granule Packaging Machine bag sizes range from 80-250mm in length and 50-180mm in width, with customizable bag sizes available. Bag materials include polyethylene (PE), polypropylene (PP), polyester (PET), nylon (PA), and aluminum foil composite film. PE and PP offer high cost-effectiveness and are suitable for common granules, while PET and PA are puncture-resistant and suitable for hard granules. Aluminum foil composite film offers strong barrier properties and is suitable for granules that require moisture and oxidation protection. Regarding packaging methods, meat granules require a complete vacuum seal, while fragile granules require a partial vacuum plus aeration. If vacuum plus nitrogen filling is selected, please confirm the machine's compatibility.

Vacuum Granule Packaging Machine Manufacturer

As a manufacturer of vacuum granule packaging machines, our factory optimizes the machine structure based on the characteristics of granular materials, ensuring high vacuum sealing and precise packaging. It is suitable for a variety of materials, including plastics, grains, and chemical granules. From core component selection to complete machine assembly, our entire process adheres to the ISO9001 quality system. Multiple rounds of performance testing precede shipment, ensuring low failure rates and exceptional reliability. We can also customize our machines based on your pellet production capacity, functionality, and other requirements. We welcome your visit for a trial run with your materials!