Mini stand-up pouch packaging machine

Mini stand-up pouch packaging machines range in price from $900 to $8,000. These compact machines take up little space and offer a wide variety of bag sizes. Production speed: Up to 50 bags per minute. Metering methods: Supports various metering methods, including screw and measuring cup filling. Packaging materials: Suitable for roll film such as aluminum foil and laminate film. Feature options: Optional features include coding, nitrogen filling, and leak detection.

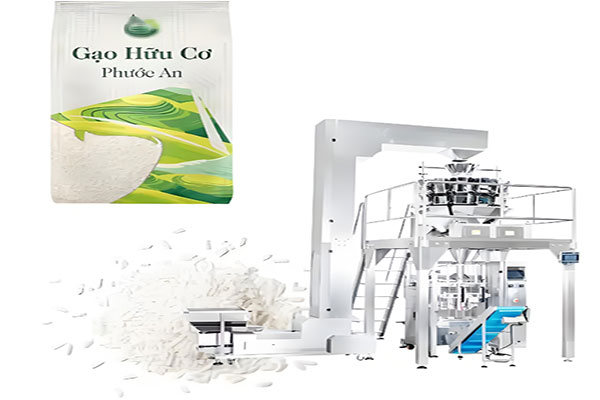

What is a Mini stand-up pouch packaging machine?

Mini stand-up pouch packaging machine are used to package liquids and granular materials. Commonly used in supermarkets for beverages and nuts are standard stand-up pouches, zippered stand-up pouches, and spouted stand-up pouches, which are both aesthetically pleasing and portable.

Compact and compact, these machines can pack 10-20 bags per minute in economical models, while mid-range and high-end models can reach 30-60 bags per minute. The packaging size range is generally 60-150mm wide and 55-300mm long. Prices for budget models range from $900 to $2700, while mid-range and high-end models range from $2800 to $5500. Models with more advanced features range from $5700 to $9500.

Mini stand-up pouch packaging machine with different bag types

What are the advantages of the Mini Stand-Up Pouch Packaging Machine?

The Mini Stand-Up Pouch Packaging Machine can customize bag shapes, ranging from convenient travel bags to large bags for cat food. Bags are available in a variety of materials, including aluminum-plastic composite film, standard plastic composite film, and transparent high-barrier film, meeting diverse sealing, light-proof, and moisture-proof requirements. It prevents liquid materials from leaking and protects granular materials from moisture. The machine also has a relatively small footprint and is easy to operate, requiring minimal training.

Mini Stand-Up Pouch Packaging Machine Packaging Process

The Mini Stand-Up Pouch Packaging Machine first delivers the packaging film roll through the unwinding mechanism. The film is then heat-pressed or mechanically folded into a stand-up pouch prototype by the former and initially sealed. A metering device then precisely weighs granules, powders, liquids, and other materials, injecting them into the pouch through the feed channel to ensure consistent weight for each bag. An exhaust mechanism then removes excess air from the bag, and a heat-sealing mechanism reseals the pouch. Temperature, pressure, and timing control ensure a secure, leak-proof seal. Finally, a cutting mechanism cuts the continuous pouch into individual packages, which are then conveyed to the finished product area via a conveyor belt.

Mini Stand-Up Pouch Packaging Machine Types

Mini Stand-Up Pouch Packaging Machine for Granules

Equipped with either a measuring cup or screw-type precision metering mechanism, this machine accommodates unevenly sized grains, such as grains, to prevent clumping and jamming. A venting mechanism is installed before the bag seal to reduce air trapped in the bag and extend the shelf life of the product. Multiple anti-vibration features are included on the machine body to ensure stable grain feeding. For single grains with a diameter of 1-15mm, the typical speed is 30-60 bags/minute. For grains with good flowability (such as coffee granules), some models can increase the speed to 70 bags/minute.

Mini Stand-Up Pouch Packaging Machine for Powders

A closed feeding channel and negative pressure vacuum system prevent powder contamination. The metering element is a wear-resistant screw, suitable for fine powders such as protein powder, preventing sticking and metering errors. An anti-stick structure is installed at the seal to prevent powder residue from affecting the seal. For powders with a fineness of 80-200 mesh, the typical speed is 25-50 bags/minute. Due to the dust generation associated with powders, the feeding rate must be controlled.

Mini Stand-Up Pouch Packaging Machine for Liquids

The machine is equipped with a drip-proof filling nozzle to prevent liquid dripping and contamination of the bag. Some models feature a heating and constant temperature system, making it suitable for easily solidifying liquids such as honey and syrup. The sealing system utilizes a dual heat seal and pressure seal to prevent seal failure caused by liquid residue. For low-viscosity liquids such as juice and toner, the machine's packaging speed is 35-65 bags/minute. For high-viscosity liquids such as sauces and creams, the speed is reduced to 20-40 bags/minute due to filling speed limitations.

Mini Stand-Up Pouch Packaging Machine for Irregular Materials

This machine uses a vibrating or belt conveyor to process bulk and irregular materials such as candy, freeze-dried fruit, small hardware, and Chinese herbal medicine slices, preventing jams. Equipped with a photoelectric positioning system, it ensures the material is placed centrally in the bag, enhancing packaging aesthetics. The seal height is flexibly adjustable to accommodate materials of varying thicknesses. For materials weighing 5-50g, the machine typically processes 20-45 bags/minute. This ensures smooth material transport and prevents damage.

Mini Stand-Up Pouch Packaging Machine Parameters

Mini Stand-Up Pouch Packaging Machine Parameters for Liquids

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | stand-up pouches, spout pouches, 3-side, 4-side sealing bags, handbags, zipper bags, compound bags, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed |

20-45bags/min(speed is determined by the product filling quantity) |

25-50bags/min(speed is determined by the product filling quantity) |

20-50bags/min (speed is determined by the product filling quantity) |

20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of product | |||

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | |

| Collocation | Screw metering, screw elevator | |||

Mini Stand-Up Pouch Packaging Machine Parameters for Granules

| Type | Automatic Mini Doypack Premade Zipper Pouch Granular Packing Sealing Machine | ||

| LDB-200 | LDB-300 | LDB-430 | |

| Bag Material | Multi-layer Composite Premade Bag(e.g.: PET/PE) | ||

| Premade bag type | 3-sides sealing bag, stand-up bag) | ||

| Upgraded Bag Type |

(Need additional purchase of functional device) |

Gusset Bag, Zipper Bag, box bag (Need additional purchase of functional device |

|

| Bag size | 70mm≤W≤150mm | 80mm≤W≤300mm | 80mm≤W≤300mm |

| 70mm≤L≤150mm | 100mm≤L≤300mm | 100mm≤L≤430mm | |

| Speed | 0~60bags/min | 0~15bags/min | |

| Sealing Type | Straight grain, pitch is 1mm (Optional reticulate) | ||

| Sealing Width | 10mm(5--20mm) can be customized | ||

| Voltage | 220V, Single-phase,50/60HZ, 1.2KW | ||

| Air Pressure | 0.65Mpa | ||

| Air Consumption | Standard machine, no additional function | ||

| Body Dimension | 1770*600*1230mm | 1770*600*1360mm | |

| Packing Dimension | 1860*710*1550mm | 1860*710*1650mm | |

| Export non-fumigation wooden case | |||

Mini Stand-Up Pouch Packaging Machine Price

A basic semi-automatic Mini Stand-Up Pouch Packaging Machine costs approximately $5,000 to $7,000, making it suitable for small-scale production. Mainstream fully automatic models are the market's top choice, typically priced between $9,000 and $20,000. They can perform bag making, filling, and sealing operations in one machine. Prices are for reference only and vary greatly depending on the machine model, functionality, and material. Contact the supplier for a quote.

Mini stand-up pouch packaging machine supplier

Our factory has been specialized in manufacturing for 15 years and can customize the machine's functions and bag size to meet customer needs. Our metering accuracy is within ±1%. Our Mini stand-up pouch packaging machine is easy to operate and comes with operating instructions, ensuring peace of mind. We can also recommend the appropriate packaging machine model based on the material type, minimizing procurement costs. We welcome your request for a trial with your materials.

Mini Stand-Up Pouch Packaging Machine Applications

Mini Stand-Up Pouch Packaging Machines are commonly used in food, daily chemicals, and pet supplies. They can package a wide range of products, including potato chips, pistachios, raisins, soft candies, infant formula, bulk tea, oatmeal, sesame oil, millet, laundry detergent, shampoo, and dog food.