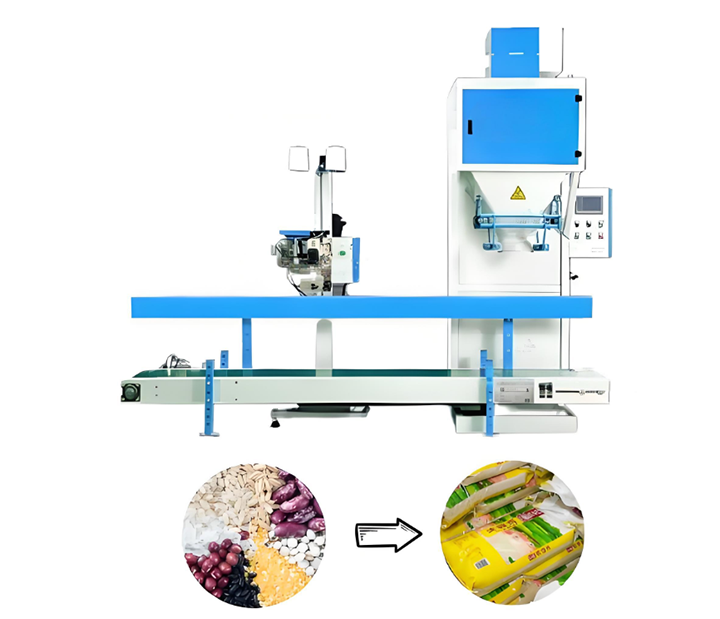

Semi-automatic granule packaging machine

Semi-automatic granule packaging machines cost around$2,000 to $7,000. Metering methods include gravimetric, volumetric, and screw-type. Production Capacity: 10-40 bags/minute Measuring Range: 1-20kg Accuracy: ±0.5-1% Bag Size: 50-200mm Power Supply: 220V 50/60Hz

What is a semi-automatic granule packaging machine?

Semi-automatic granule packaging machine is suitable for packaging granular materials such as candy, nuts, seeds, and pharmaceutical capsules. These materials range in shape from regular spheres to flakes and irregular particles, with sizes typically ranging from 0.5mm to 20mm. It is suitable for materials with a certain degree of fluidity. Materials with poor fluidity, such as goji berries, require a vibrating plate or agitator. Parts in contact with corrosive chemicals or high-hygiene foods/pharmaceuticals are constructed of 304 or 316L stainless steel, meeting corrosion resistance and food-grade standards. Metering methods include volumetric, gravimetric, and screw. Production speeds range from 20 to 60 bags per minute, and prices range from $2,000 to $7,000, depending on configuration.

What are the features of a semi-automatic granule packaging machine?

This Semi-automatic granule packaging machine utilizes manual assisted loading and unloading, combining the advantages of both automation and manual operation. Its compact design and minimal footprint make it suitable for limited spaces. It utilizes a touchscreen control system, allowing for digital setting of parameters such as bag length, temperature, and weight. A photoelectric tracking system ensures alignment of packaging patterns and allows for switching between hot and cold sealing. Flexible adjustments allow for quick replacement of the hopper, metering device, or packaging film to adapt to different granular material characteristics and packaging requirements, eliminating the need for extensive component replacement. It can accommodate a variety of film materials, such as PE/PP and composite films, meeting sealing and moisture-proof requirements.

Semi-automatic granule packaging machine specifications

| Model | DCS-YB25 |

| Weighing Range | 10kg-50kg |

| Precisions | ±0.2%FS |

| Packing Capacity | 120-240bag/hour |

| Power supply | 220V/380V, 50HZ, 1P/3P ( Customized) |

| Power (KW) | 1kw |

| Air source pressure | 0.4-0.6Mpa |

| Dimension | 2200*800*2600 mm |

| Weight | 600kg |

Semi-automatic granule packaging machine equipment types

Volumetric semi-automatic granule packaging machines control the feed rate by adjusting the volume of a measuring cup or rotating disk. Their advantages are simple structure, high speed, and low cost. However, their disadvantages are relatively low accuracy and susceptibility to material density fluctuations. Therefore, they are primarily suitable for lightweight, fluid granules that require less precision, such as puffed foods, potato chips, and seeds. Prices typically range from $1,500 to $3,000.

Screw-type semi-automatic granule packaging machines precisely control the feed rate by controlling the number of revolutions of a precision screw. This method offers high accuracy, a wide range of adjustments, and the ability to accommodate a variety of tiny granules and powder-granule mixtures. Its disadvantages are relatively slow speed and somewhat troublesome cleaning. They are commonly used for products requiring high precision, such as condiments, pharmaceutical granules, milk powder, coffee powder, and pesticides. Prices range from $4,000 to $7,500.

Weighing-type semi-automatic granule packaging machines: Utilizing high-precision sensors for real-time weighing, discharging material immediately stops when the set target is reached. This is the most accurate of the three methods, and its weight is virtually unaffected by variations in material density and flowability. However, it is the most expensive to manufacture and typically operates at the slowest speed, making it particularly suitable for packaging high-value products with extremely stringent weight requirements, such as high-end health supplements, precious medicinal herbs, and tea. Prices range from $4,000 to $9,000.

What is the price range for a semi-automatic granule packaging machine?

The price range for a semi-automatic granule packaging machine is generally around $300 to $5,000. Simple, small semi-automatic granule weighing and packaging machines are less expensive, such as some semi-automatic stainless steel granule powder bag weighing and filling machines with a capacity of 100-2500g, which cost around $300-700. Semi-automatic granule packaging machines with more features and higher precision, such as those with weighing and filling functions, cost around $2,000-5,000. For example, a semi-automatic granule packaging machine for nuts, coffee beans, grains, and rice costs around $2,400-2,800.

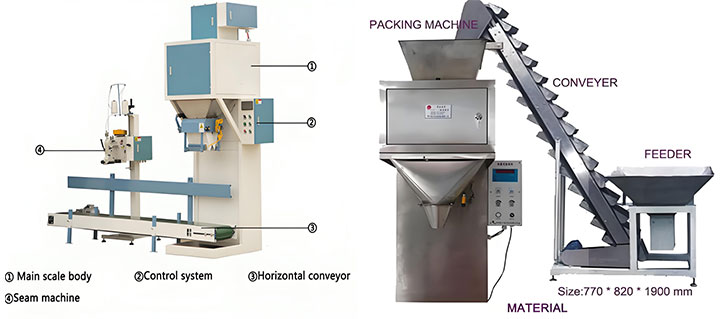

What are the structural components of a semi-automatic granule packaging machine?

The core structure of a semi-automatic granule packaging machine includes: frame: a carbon steel or stainless steel support frame; metering system: a measuring cup, screw, or weighing module; bag maker: a mold assembly that forms the bag; transmission system: a servo motor drives the film drawing; heat sealing system: a heating rod and pressure mechanism; control system: a PLC and touch screen; and a hopper: a material storage and unloading device.

Semi-automatic granule packaging machine workflow

The semi-automatic granule packaging machine's workflow is as follows: First, a person manually pours the granules to be packaged into the machine's hopper. The machine is then started, and a feeding mechanism inside the hopper, such as a screw feeder or bucket elevator, delivers a measured amount of granules to the discharge port. Next, a person manually places a packaging bag over the discharge port. The machine senses the bag and automatically discharges the granules, ensuring that each bag meets the specified weight. After discharge, a person manually removes the bag containing the granules and places it in a sealing device. The machine seals the bag using heat or pressure, and the sealed finished product is manually collected, completing the entire granule packaging process.

Main Features of the Semi-automatic Granule Packaging Machine

The semi-automatic granule packaging machine offers the following four key advantages through its structural components and functions:

Easy to operate: No extensive training is required, and workers can quickly master the operating procedures, reducing labor costs and learning curves. It is suitable for small and medium-sized production scenarios.

High Packaging Precision: Equipped with a precise metering device, it effectively controls fill volume errors for granular materials, reducing material waste, ensuring consistent weight per bag, and improving product quality.

Flexible and adaptable: Compatible with a variety of granule forms, including loose, fluid, and slightly cohesive, the machine can flexibly adjust packaging sizes between 10g and 25kg.

Excellent Cost-Effectiveness: Compared to fully automatic equipment, it offers lower purchase and maintenance costs and lower energy consumption, meeting the needs of small and medium-sized production volumes while keeping initial investment and operating costs under control, resulting in a rapid payback period.

Applications of Semi-Automatic Granule Packaging Machines

Semi-automatic granule packaging machines are suitable for small and medium-sized manufacturers, balancing efficiency and cost. They are used in the food industry for packaging nuts, candy, and pet food; in the pharmaceutical industry for packaging tablets and capsules; in the chemical industry for packaging resin granules and fertilizers; and in the daily chemical industry for packaging laundry detergents and fragrance beads. Their flexibility and adaptability make them a popular choice for packaging applications across multiple industries.