Vertical candy packaging machine

Vertical candy packaging machines have filling capacities ranging from 10 to 2500 grams. They offer automatic feeding, sealing, and date printing. Prices range from $5,000 to $20,000. Applicable materials: Block candies such as hard candies, soft candies, and chocolate chips. Packaging methods: Bags with back seals or three-side seals. Packaging speed: 20-80 bags/minute. Control system: Servo motor, PLC touch screen control.

What is a vertical candy packaging machine?

Vertical candy packaging machine can package hard candies, soft candies, crispy candies, and candies of various shapes. When producing sugar-free candies or probiotic candies, the machine also supports nitrogen filling and vacuum packaging to extend the shelf life.

The vertical candy packaging machine offers a variety of packaging specifications, with bag lengths generally ranging from 80-300mm and bag widths from 80-200mm, meeting packaging needs for weights ranging from 10 to 2000g. Production capacity typically ranges from 15 to 70 bags per minute, adapting to varying candy production scales. Equipment prices typically range from US$6,000 to US$20,000. The equipment structure includes a main frame, feeding system, metering device, forming and sealing mechanism, and control system. It automatically completes a series of functions, including feeding, metering, bagging, sealing, date printing, and outputting finished products.

What are the advantages of vertical candy packaging machines?

Vertical candy packaging machines offer significant advantages in many areas. In terms of flexibility, changeovers are convenient, allowing for quick switching between different candy packaging formats. These machines accommodate a variety of candies, including hard and soft candies, meeting the needs of small-batch, multi-category production. The drive system primarily utilizes a servo drive, ensuring stable operation and precise control of the packaging process, minimizing material loss and equipment failures. A wide range of metering methods are available, including volumetric methods for regular candies and gravimetric methods for ensuring accurate metering of soft candies and other products, meeting food net content standards. Bag making boasts high accuracy, typically within ±1mm, ensuring a uniform packaging appearance. The user interface is typically a high-definition touchscreen, supporting recipe storage and fault alerts, making it easy for even novice operators to quickly master the process and improving overall production efficiency.

Vertical Candy Packaging Machine Technical Parameters

|

Model

|

ZH-BL10

|

|

System Output

|

≥ 8.4 Ton/Day

|

|

Packing speed

|

30-70 Bags / Min

|

|

Packing Accuracy

|

± 0.1-1.5g

|

|

Bag size(mm)

|

(W) 60-200 (L)60-300 for 420VFFS

(W) 90-250 (L)80-350 For 520VFFS

(W) 100-300 (L)100-400 For 620VFFS

(W) 120-350 (L)100-450 For 720VFFS

|

|

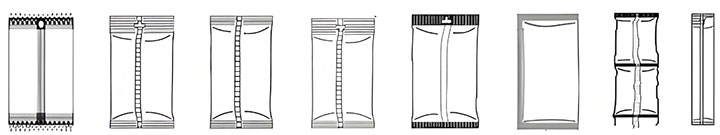

Bag type

|

Pillow bag, standing bag (gusseted), punch, Linked bag

|

|

Range of measuring (g)

|

5000

|

|

Thickness of film (mm)

|

0.04-0.10

|

|

Packing Material

|

laminated film such as POPP/CPP, POPP/ VMCPP, BOPP/PE,

PET/ AL/PE , NY/PE, PET/ PET,

|

|

Power Parameter

|

220V 50/60Hz 6.5KW

|

Vertical Candy Packaging Machine Types

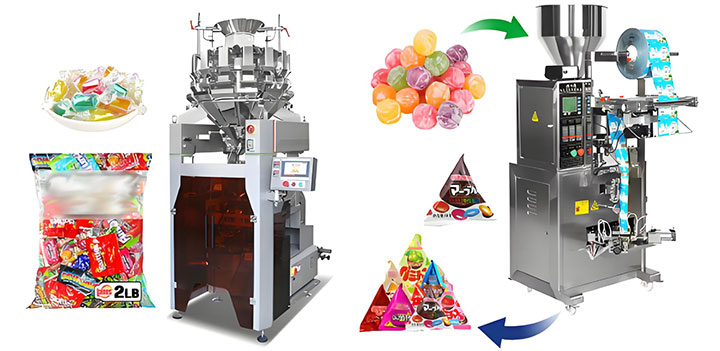

Common vertical candy packaging machines include vertical continuous packaging machines and multi-head combination weigher-based vertical packaging machines. Each type is suitable for packaging candies with different characteristics, allowing for customized selection.

Vertical continuous packaging machines utilize roll film to automatically complete bag making, metering, filling, and sealing. They are compact and easy to change over, supporting a variety of packaging styles, including pillow bags and triangular bags. This machine is suitable for individually counted, regular-sized products such as hard candies, soft candies, and chocolate chips. With a speed of 60-150 bags/minute and moderate output, it's ideal for flexible production of small batches of multiple varieties.

The multi-head combination weigher-type vertical candy packaging machine, based on a high-precision computerized combination weigher, automatically feeds and packages the products after precise weighing. It excels at handling fragile or irregularly shaped materials. With speeds of 80-200 bags/minute and extremely high output, it's ideal for products sold by weight, such as gummy candies, nougat, and bulk chocolate. It's an ideal machine for large-scale production.

Vertical Candy Packaging Machine Packaging Materials

The vertical candy packaging machine's packaging materials, bag shapes, and specifications vary, making it suitable for a wide range of candy types. Bag lengths typically range from 80-500mm, and bag widths from 60-350mm. The following is a description of the materials and types of packaging bags.

Vertical candy packaging machines can use a variety of packaging films, the most common of which are as follows:

BOPP film: Features excellent transparency and heat-sealing properties, making it suitable for high-speed packaging. It is often used for packaging small candies, biscuits, chocolates, and other lightweight foods. For example, low-temperature, low-friction BOPP film can be used for lightweight candy packaging.

PET film: Features high transparency, good mechanical strength, and excellent barrier properties, effectively protecting candies from moisture and oxidation. PET twist film is suitable for packaging candies such as toffee and nougat. In addition, composite films of PET and other materials, such as PET/CPP and PET/PE, are also widely used for candy packaging.

PE film: Features excellent flexibility and moisture resistance. PE twist film can be used for packaging hard candies, chocolates, toffees, and more. Food-grade PE coated paper can also be used for candy packaging, effectively blocking moisture and grease.

BOPA film: Features oil and organic solvent resistance, and excellent oxygen barrier properties, making it suitable for packaging fatty candies such as chocolate.

The vertical candy packaging machine can produce the following main types of bags:

Pillow bags: The most common bag type, suitable for packaging various block and granular candies, such as fruit candies and toffee candies.

Three-side seal bags: Offer a secure seal and excellent airtightness, effectively preserving the quality of candies and suitable for packaging high-end candies and chocolates.

Back seal bags: Commonly used for packaging irregular block and granular candies, such as lollipops.

Hanging hole bags: Convenient for hanging display, suitable for candies that need to be prominently displayed on shelves.

Special-shaped bags: Such as stand-up pouches and zipper bags offer a unique appearance and ease of use, making them suitable for packaging high-end candies or candies that require frequent use.

Steps for packaging candies using a vertical candy packaging machine

The vertical candy packaging machine operates as follows: First, the film roll is drawn into the former and folded into a cylindrical shape. A longitudinal sealing device then heat-seals the sides of the film. The candies are accurately weighed by a metering device (such as a measuring cup or vibrating plate) or by a combination scale above before being placed into the formed film bag. The horizontal sealing device heat-seals the film underneath the candy and cuts it, forming a complete, individual package. Finally, the finished candy is discharged via a conveyor belt.

Candy types packaged by the vertical candy packaging machine.