Moisture-Proof Granule Packaging Machine

The Moisture-Proof Granule Packaging Machine is an automated device used to accurately measure and automatically encapsulate moisture-sensitive granular products (such as food, pharmaceuticals, and chemical raw materials) in moisture-proof packaging material. Prices range from$5,000 to $20,000. Production Capacity: 30-60 bags/minute Accuracy: ±0.1%-0.2% Film Width: ≤420mm Power Supply: 220V 50/60Hz

What is a Moisture-Proof Granule Packaging Machine?

Granular materials, such as sugar, nuts, fertilizers, and seeds, are often hygroscopic, easily oxidized, and volatile. The Moisture-Proof Granule Packaging Machine provides precise sealing to prevent moisture and preserve freshness.

The metering method of the Moisture-Proof Granule Packaging Machine must match the characteristics of the granules. Spiral metering (with an accuracy of ±0.5%) is suitable for granules with good flowability, while gravimetric metering (with an accuracy of ±0.2%) is more suitable for irregular or sticky granules. Bags are sealed with either three or four sides, ensuring a complete seal line. Automation levels range from semi-automatic stand-alone machines to fully automated integrated production lines equipped with automatic bagging, weight sorting, metal detection, and robotic palletizing. Semi-automatic machines have an output of approximately 300-800 bags per hour; vertical machines can produce 800-3000 bags per hour; horizontal machines are suitable for large granules, with an output of 500-1500 bags per hour; and fully automatic high-capacity models can reach 1000-5000 bags per hour. Prices range from $5,000 for semi-automatic equipment to $20,000 for complete production lines.

Moisture-Proof Granule Packaging Machine Packaging Performance

The packaging performance of a moisture-proof granule packaging machine directly affects the shelf life and quality of the granule product, with key factors affecting the sealing method, tightness, and packaging format.

Common sealing types include heat sealing, which fuses the film by heating and is suitable for plastic film bags, providing a stable seal. Ultrasonic sealing uses high-frequency vibrations to generate heat without direct contact with the packaging material, thus preventing damage to heat-sensitive particles caused by high temperatures. Seam sealing with waterproof tape is suitable for large packages of particles over 50kg, protecting them from rain and moisture during transportation.

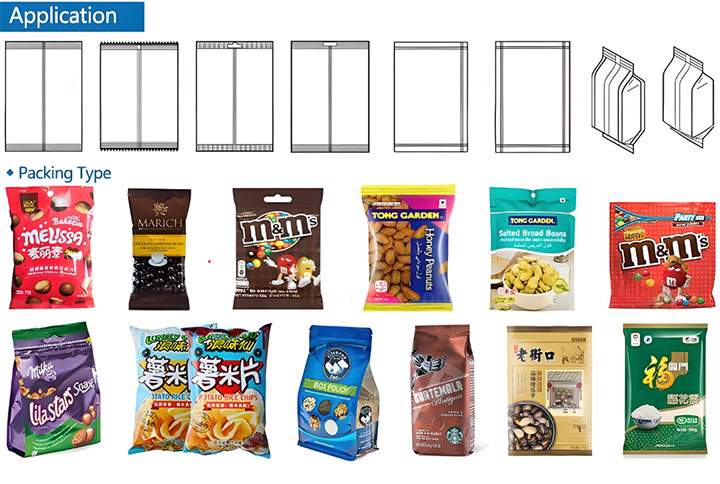

Packaging formats are flexibly designed based on the application scenario. Small-volume packages (10-50g) are often made with three- or four-side-sealed bags, suitable for retail use. Medium-volume packages (100-500g) often use stand-up pouches with built-in zippers for easy re-sealing after repeated use. Large-volume packages (1-50kg) are primarily made with woven bags or aluminum-plastic composite bags, some of which have built-in moisture-proof linings for further moisture-proofing.

Moisture-Proof Granule Packaging Machine Parameters

Roll film forming flat bag filling and sealing machine parameters:

| Model | 110N/110NZ | 130N/130NZ | 180N | 210N | 240N | 180ND | 210ND | 240ND | 280ND | 330ND | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pouch Size(mm) | Min | 40*80 | 60*80 | 70*130 | 70*130 | 75*85 | 60*90 | 70*130 | 70*130 | 70*130 | 75*130 |

| Max | 110*160 | 130*180 | 180*225 | 210*225 | 240*225 | 90*180 | 105*300 | 120*300 | 140*300 | 160*300 | |

| Fillling Volume | ml | 100 | 160 | 400 | 750 | 1000 | 100 | 120 | 150 | 200 | 400 |

| Packaging Speed | ppm | ≤60 | ≤60 | ≤60 | ≤55 | ≤50 | ≤100 | ≤120 | ≤120 | ≤100 | ≤90 |

| Machine Size | mm | 2650*900*1460 | 2850*920*1460 | 3500*970*1450 | 4000*970*1450 | 4500*970*1460 | 3500*970*1450 | 4500*970*1450 | 5200*970*1450 | 6500*970*1460 | 7200*970*1460 |

| Machine Weight | kg | 1300 | 1500 | 1800 | 2000 | 2100 | 1800 | 2000 | 2100 | 2200 | 2300 |

| Power | kw | 3.5 | 3.5 | 5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Air Consumption | l/min | 200 | 200 | 200 | 300 | 300 | 200 | 300 | 300 | 300 | 300 |

The Parameters of Roll Film Forming Doypack Filling Sealing Machine:

| Model | 180S | 240S | 280S | 180SD | 240SD | 280SD | 330SD | |

|---|---|---|---|---|---|---|---|---|

| Pouch Size(mm) | Min | 80*130 | 90*130 | 90*140 | 70*110 | 90*125 | 90*125 | 90*125 |

| Max | 182*250 | 240*300 | 280*300 | 90*225 | 120*250 | 140*250 | 165*250 | |

| Fillling Volume | ml | 1000 | 2000 | 3000 | 300 | 500 | 500 | 700 |

| Packaging Speed | ppm | ≤60 | ≤60 | ≤50 | 60-120 | 60-120 | 60-100 | 60-90 |

| Machine Size | mm | 6500*970*1450 | 7200*9700*1460 | 8000*1200*1800 | 6900*970*1450 | 7200*970*1460 | 8500*1100*1460 | 9500*1100*1460 |

| Machine Weight | kg | 2000 | 2300 | 3400 | 2100 | 2500 | 2500 | 2500 |

| Power | kw | 8 | 9 | 9.5 | 8.8 | 9.8 | 9.8 | 15.8 |

| Air Consumption | l/min | 300 | 400 | 650 | 400 | 400 | 400 | 400 |

Moisture-Proof Granule Packaging Machine Types

Based on their structure, function, and production capacity, Moisture-Proof Granule Packaging Machines can be primarily categorized into the following types. Their characteristics are compared below:

Screw Moisture-Proof Granule Packaging Machine: They offer high metering accuracy (±0.5%-1%) and are suitable for fine particles with moderate flowability, powder-granular mixtures, and dust-prone materials. They precisely meter by controlling the number of screw revolutions. Their production speed is moderate, typically 30-60 bags/minute. They are typically semi-automatic or fully automated, requiring manual bagging or a combination of automatic bagging.

Volumetric Cup Moisture-Proof Granule Packaging Machine: They offer relatively low metering accuracy (±1%-2%) and are more suitable for materials with good flowability and uniform particle size (such as seeds, grains, and candy). They adjust the volume of the volumetric cup to determine the desired quantity. Their production speed is relatively fast, reaching 60-100 bags/minute. Their automation levels range from semi-automatic to fully automated.

Combination weigher (multi-head weigher) Moisture-Proof Granule Packaging Machine: This is the mainstream choice for high-speed, high-precision packaging. They offer extremely high weighing accuracy (±0.1% to 0.5%) and are suitable for nearly all granular materials, especially for industries with stringent weight requirements (such as high-end foods and health supplements). The weighing process uses a computerized combination of multiple weighing hoppers to quickly select the combination closest to the target weight for unloading. Production speeds are extremely high, exceeding 200 bags per minute. They are highly automated, with all machines being fully automatic and integrated into automated production lines.

Moisture-Proof Granule Packaging Machine Purchase

The price of a moisture-proof granule packaging machine varies significantly depending on its technical complexity, automation level, and configuration. Basic semi-automatic screw or volumetric packaging machines are more affordable, typically ranging from $5,000 to $9,000, making them suitable for startups or small-batch production. Standard fully automatic packaging machines (such as single vertical machines) equipped with automatic bagging and control systems range in price from approximately $10,000 to $20,000. High-performance fully automatic combination weigher packaging lines, which integrate combination weigher metering, high-speed bag making, filling, sealing, weight detection, metal detection, and even robotic palletizing, form a complete solution. These are the most expensive, typically starting at over $20,000, depending on the configuration.

Moisture-Proof Granule Packaging Machine Industry Applications

Moisture-Proof Granule Packaging Machines are used in a wide range of industries, covering nearly all packaging applications for granular materials requiring moisture protection. In the food industry, they are used to package coffee beans, tea, candy, nuts, pet food, seasonings (such as chicken essence and sugar), freeze-dried fruit and vegetable granules, and more, ensuring flavor and a crisp texture. The pharmaceutical industry has extremely high requirements for them, packaging granular powders, Chinese herbal medicine slices, herbal remedies, and capsule granules, which must meet GMP standards to ensure drug purity and efficacy. The chemical industry is another major application area, used for packaging resin pellets, plastic masterbatches, dyes, desiccants, seeds, fertilizers, and more. These machines require corrosion resistance and absolutely reliable sealing to prevent moisture-induced caking and chemical reactions. They also play an indispensable role in the production of electronic components (such as moisture-proof silica gel desiccants) and household chemicals (laundry detergents and laundry beads).