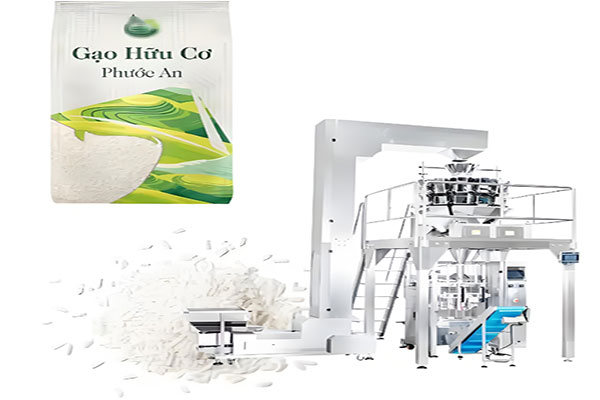

Automatic Rice Packing Machine

Automatic Rice Packing Machine the packaging capacity of common equipment is 300 to 1200 bags per hour, covering a variety of production capacity requirements from small processing points to large grain distribution centers. The price is around $2,000 - $10,000. Packaging range: 500g~5kg (customizable to 10kg or more) Weighing accuracy: ±1~2g Packaging speed: 15~40 bags/minute (multi-head weigher can reach 60 bags/minute) Bag type support: pillow bag, stand-up bag, self-supporting zipper bag, etc. Packaging materials: composite film, PE film, aluminum-plastic film, etc.

What is Automatic Rice Packing Machine?

Automatic Rice Packing Machine packages rice, paddy, and other grains at a speed of 20-60 bags per minute. It utilizes a high-precision weighing system, maintaining a weight error within ±1.0 gram, minimizing waste. The machine boasts a high degree of automation, completing bag making, filling, sealing, and outputting automatically, saving labor. It is compatible with a variety of packaging materials, including polyethylene, woven polypropylene, and composite paper. Equipped with an advanced control system and touchscreen interface, it allows for easy parameter settings. The machine operates stably and is suitable for conventional workshop environments. Depending on the configuration and production capacity, the market price typically ranges from US$2,000 to US$10,000.

Automatic Rice Packing Machine can be divided into vertical packaging machine, bag-feeding packaging machine and combination weighing packaging machine according to the structure and degree of automation, which are suitable for different production scenarios. The vertical machine has a compact structure and is suitable for small and medium-sized production; the bag-feeding machine is flexible and efficient, suitable for multi-specification packaging; the combination weighing machine is accurate and high-speed, meeting the needs of large-scale production. According to the production capacity, the packaging capacity of common equipment is 300 to 1200 bags per hour, covering a variety of production capacity requirements from small processing points to large grain distribution centers. The whole machine is usually composed of a hoist, a weighing system, a bag making device, a sealing and cutting device, and a finished product conveyor belt. The various components work together to realize the automation of the entire process from material transportation, automatic metering, packaging and forming to finished product output. It is easy to operate, efficient and stable.

What are the advantages of Automatic Rice Packing Machine?

Automatic Rice Packing Machine has the significant advantage of automation, which can greatly reduce manual intervention and labor costs, while improving packaging speed and production consistency, and is suitable for large-scale continuous production needs. Its equipment has excellent compatibility and can flexibly adapt to various specifications of packaging bags, including stand-up bags, self-supporting bags, four-side sealed bags and other different types, and supports custom parameter settings (such as temperature, speed, filling volume, etc.) through the touch screen interface to meet the personalized packaging process requirements of different products. The equipment is equipped with a high-precision weighing sensor and a closed-loop control system to achieve a measurement accuracy of ±0.1%-0.3%, effectively reducing raw material waste.

Automatic Rice Packing Machine Parameters

| Packing Range | 500g to 5kg (customizable for 10kg and above) |

| Weighing Accuracy | ±1–2 grams |

| Packing Speedt | 15–40 bags/min (up to 60 bags/min with multi-head weigher) |

| Supported Bag Types | Pillow bags, vertical bags, stand-up zipper bags, etc. |

| Packaging Materials | Composite film, PE film, aluminum-plastic film, etc. |

| Power Supply | AC 220V/50Hz or AC 380V/60Hz |

| Power Consumption | 2–5KW |

| Machine Dimensions | Approx. 2000mm × 1500mm × 2500mm (varies by model) |

| Control System | PLC + touch screen (HMI), supports multi-language operation |

What is Automatic Rice Packing Machine Principle?

Automatic Rice Packing Machine mainly realizes the packaging of rice by integrating multiple automation modules such as weighing, filling, bag making, sealing and conveying. Its core principle is to use an electronic weighing system to accurately control the weight of each bag of rice, and then drive the servo motor to fill the quantitative rice into the automatically formed packaging bag, and then output the finished product after sealing. Some high-end equipment is also equipped with a vacuum system, an inflation system (such as nitrogen preservation) and a metal foreign body detector to ensure food quality and preservation effect.

Automatic Rice Packing Machine Price

The price of Automatic Rice Packing Machine mainly depends on the configuration, production capacity and degree of automation. Different types of equipment are suitable for enterprises of different sizes. The higher the functional integration, the more expensive the price.

Small semi-automatic packaging machines cost about $3,000 to $6,000, suitable for home workshops or small batch OEM, with a daily production capacity of about 2 to 5 tons, with basic weighing and sealing functions, and require manual loading.

Medium-sized fully automatic vertical packaging machines cost $10,000 to $20,000, suitable for medium-sized processing plants, with a daily production capacity of 10 to 20 tons, and with multi-functional integrated operations such as automatic weighing, bag making, sealing, and coding.

High-speed multi-head combination weigher packaging machines are suitable for large-scale production lines, with a price of $25,000 to $50,000, a daily production capacity of more than 30 tons, and a multi-head high-precision weighing system to achieve high-speed and continuous automatic packaging.

Automatic Rice Packing Machine Application?

Automatic Rice Packing Machine is widely used in grain processing, food production and logistics warehousing, and is suitable for quantitative packaging of various granular materials such as rice, grains, and miscellaneous grains. In large rice mills, it can realize integrated operations from weighing, filling to sealing, significantly improving production efficiency; in small and medium-sized processing enterprises, semi-automatic models can flexibly adapt to the packaging needs of multiple specifications and reduce labor costs. In addition, the equipment can also be used in supermarket supply chains and e-commerce logistics to ensure that products are neatly packaged and well sealed, extending the shelf life. Some high-end models support functions such as vacuuming and nitrogen filling to meet the packaging requirements of high-end rice or organic products.

How to choose a suitable Automatic Rice Packing Machine?

The selection of Automatic Rice Packing Machine requires comprehensive consideration of multiple key factors to ensure that the equipment can meet production needs while maximizing investment benefits and ensuring stable operation in the later stage, mainly including the following four aspects:

Capacity requirements: Select matching equipment according to the daily output or order size of the factory. For example, small processing plants can choose vertical models, while large and medium-sized enterprises recommend high-capacity multi-head weigher models.

Packaging specifications: The weight range of daily packaging needs to be clarified to ensure that the equipment operates within the standard range and avoid equipment overload or idling.

Budget and return on investment: The price of equipment is proportional to its function. When the budget is limited, you can consider a semi-automatic model with high cost performance; if the core goal is to improve efficiency, you should give priority to purchasing a fully automatic combination weigher packaging machine.

Site and supporting conditions: The equipment size and gas source power supply requirements must match the existing factory conditions to avoid affecting the production progress due to insufficient supporting facilities.

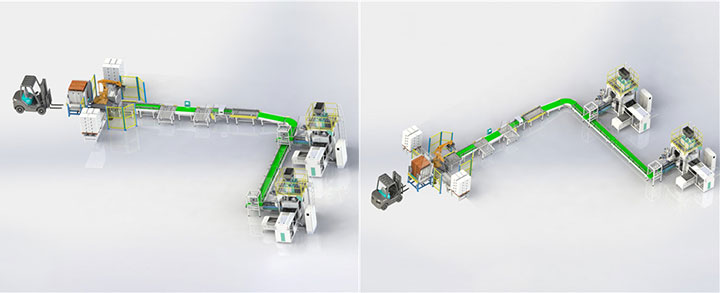

Automatic Rice Packing Machine Solution

After a rice processing plant introduced the Automatic Rice Packing Machine, it achieved efficient packaging of 4-6 bags per minute with an accuracy of ±0.5%. The equipment adopts a dual-speed spiral feeding system, which can automatically adapt to the fluidity differences of different varieties such as pearl rice and silk rice, supports 5kg to 25kg multi-specification packaging, and can complete specification switching in 3 minutes. The matching negative pressure dust removal system reduces the dust concentration in the workshop by 60%, and recycles rice grains for reuse, becoming a case of grain packaging.

Comparison of different types of Automatic Rice Packing Machine

Automatic rice packing machines are typically vertical models, and the model can be selected based on the packaging volume. Small automatic rice packing machines typically have a packaging capacity of less than 5kg and a packaging speed of 660-720 bags/hour. They occupy a small footprint and are suitable for small-scale workshops. Medium-sized machines typically have a packaging capacity of 5-25kg and a maximum packaging capacity of 4-6 bags/minute, making them suitable for medium-sized processing plants. Large-sized machines have a packaging capacity exceeding 25kg and can efficiently handle large batches of rice, making them commonly used by large rice mills.