Fully Automatic Vertical Molding Granule Packaging Machine

Wednesday December-17 2025 17:54:28

Fully Automatic Vertical Molding Granule Packaging Machine automates the packaging of granular materials using a molding device. Packaging speed varies depending on the configuration, with mid-range models ranging from 40 to 80 packs per minute, while high-speed models can reach 120 packs per minute. It can accommodate various bag sizes from 30mm long and 20mm wide to 300mm long and 200mm wide. Packaging capacity ranges from 50g to 5kg granules, depending on the size. The machine supports various packaging materials such as PE, PP, composite film, and aluminum foil. Prices range from $5,000 to $15,000.

Fully Automatic Vertical Molding Granule Packaging Machine Operation Process

The Fully Automatic Vertical Molding Granule Packaging Machine automatically completes the entire process of bag making, filling, sealing, and cutting from a roll of packaging film. It is not a machine for sealing existing bags or horizontal pillow packaging. The working process is as follows: the film roll is pulled out by a traction device and formed into a hollow cylindrical shape by a forming device. Granular material is filled into the film cylinder through a metering device from the upper hopper. Next, longitudinal and transverse sealing devices heat-seal the film, forming individual bags and then cutting them. This completes the automated packaging of the granules.

Types of Fully Automatic Vertical Molding Granule Packaging Machines

Fully Automatic Vertical Molding Granule Packaging Machines are classified according to their metering method. Two common types are volumetric cup quantitative packaging machines and multi-head combination scale quantitative packaging machines.

Volume Cup Quantitative Packaging Machines: These use pre-calibrated metering cups for metering. Packaging speed is 60-100 bags per minute. They are used for conventional granule packaging where metering accuracy requirements are not extremely high and the material has good flowability. They can produce common bag types such as back-seal bags, three-side seal bags, and four-side seal bags. Basic functions include date printing, nitrogen filling, and easy-tear opening. The price is approximately US$20,000-35,000 for the economical model.

Multi-head combination weigher quantitative packaging machine: This machine integrates a multi-head computer-controlled combination weigher as its core measurement component. Through digital weighing and computer-optimized combinations of multiple weighing hoppers, it instantly selects the combination closest to the target weight from multiple weight combinations for feeding. Packaging speed is over 80-120 bags per minute. It features high-speed weighing, automatic dispensing, forming, filling, and sealing, and supports various bag types, such as upright bags, three-side seal bags, and zipper bags. Price: Approximately $15,000–$20,000 USD.

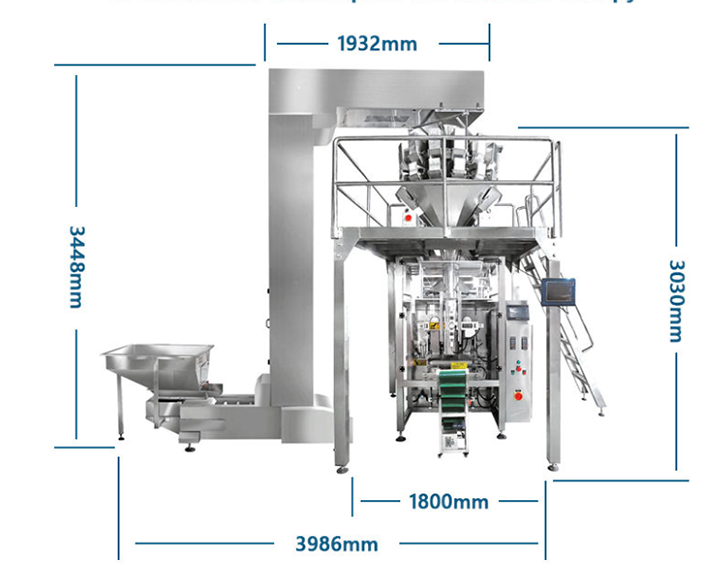

Difference between the two types: Combination weighers use dynamic gravity weighing, and their accuracy is not affected by changes in material density; while volumetric weighers use static volume measurement, and their accuracy is affected by density. Combination weigher systems are more complex and more expensive. Volumetric cup quantitative packaging machines are smaller, vertical machines compared to combination weighers, which are larger due to their multi-head weighing and Z-type conveyor systems.

Advantages of the Fully Automatic Vertical Molding Granule Packaging Machine

The Fully Automatic Vertical Molding Granule Packaging Machine operates entirely unmanned from film roll to finished product, saving manpower, reducing labor costs and errors, and ensuring consistent production of granular materials. Utilizing a vertical bag-making method, its compact structure and high vertical space utilization make it suitable for most factory layouts. Packaging bags are made on-site from flat roll film, eliminating the storage and management costs of pre-made bags. Flexible changeovers allow for rapid response to packaging design changes. Optimized for the physical properties of granular materials, the feeding is smooth and less prone to clogging. The metering method is designed for the flowability and consistency of granules, ensuring a stable and reliable packaging process.

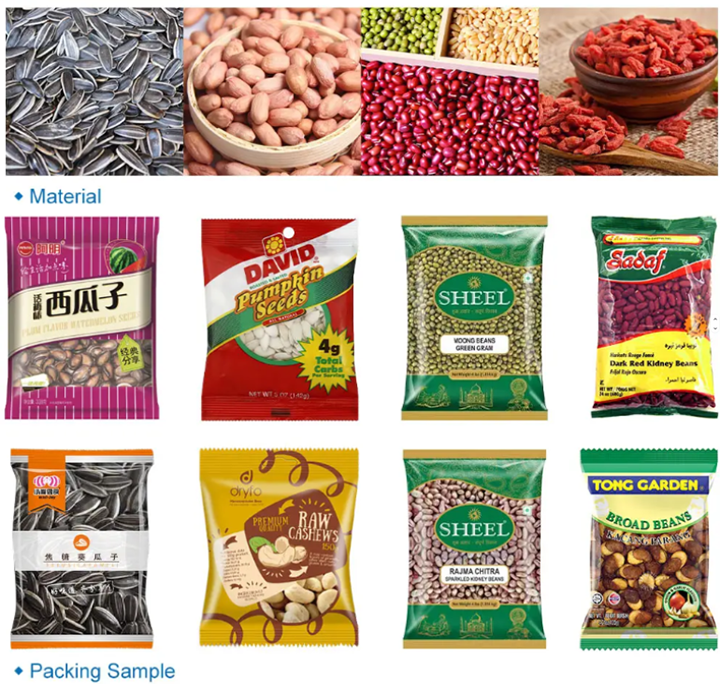

Suitable Materials for the Fully Automatic Vertical Molding Granule Packaging Machine

The Fully Automatic Vertical Molding Granule Packaging Machine is suitable for packaging granular, short strip, and small flake materials, such as nuts, candies, puffed foods, pet food, tea, coffee beans, seasonings, seeds, grains, laundry detergent, bath salts, granular health products, traditional Chinese medicine slices, screws, nuts, nails, bearing balls, plastic granules, and chemical catalysts.

Fully Automatic Vertical Molding Granule Packaging Machine Case Study

A nut processing company selected a multi-head combined weighing fully automatic vertical granule packaging machine for packaging pistachios, almonds, and cashews. The machine is equipped with 10 weighing heads and can complete high-speed packaging of 100 bags (250g each) of nuts per minute. Before using the machine, the company had to manually weigh each bag, which was inefficient and prone to errors. After using the machine, the packaging accuracy improved to ±2g, production efficiency increased by more than 5 times, and significant labor costs were saved.

The Fully Automatic Vertical Molding Granule Packaging Machine simplifies and speeds up the packaging process by integrating bag making, weighing, filling, and sealing into one machine. Whether it's a combined weighing model prioritizing accuracy and speed, or an economical volumetric cup model, it provides reliable and flexible packaging options for granule products.