Fully Automatic Small Bag Powder Packaging Machine

Friday December-12 2025 18:03:39

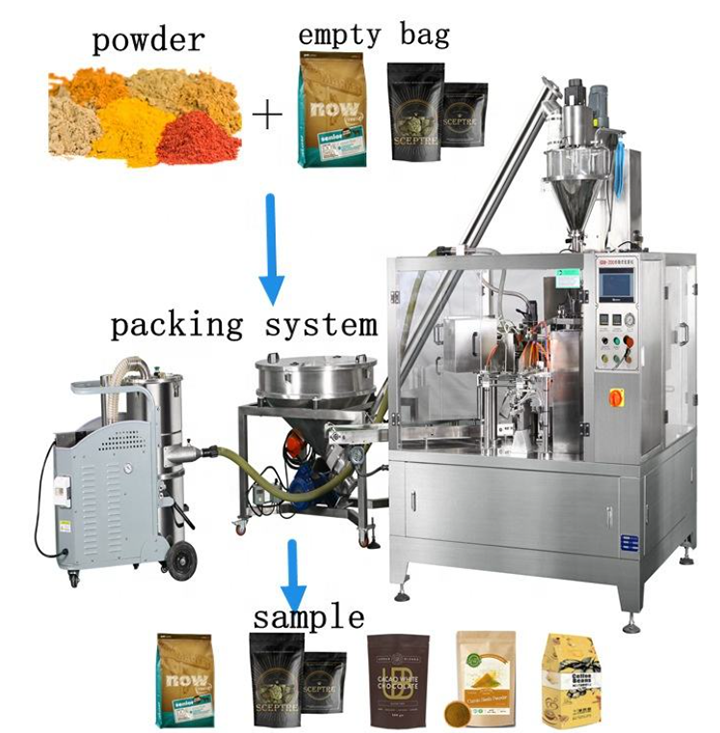

Fully Automatic Small Bag Powder Packaging Machine is capable of fully automating the metering, filling, and sealing of powders ranging from 1 gram to 200 grams. In terms of packaging speed, the machine can pack approximately 30 to 120 bags per minute, with high-speed models reaching 150 bags per minute. Equipped with a PLC control system, a touchscreen interface, and functions such as automatic deviation correction, automatic metering, and fault alarms, it boasts a high degree of automation. It supports various bag types, such as three-side seal bags, four-side seal bags, stand-up pouches, and zipper bags, greatly meeting the needs of different products and markets.

How does the Fully Automatic Small Bag Powder Packaging Machine package powder?

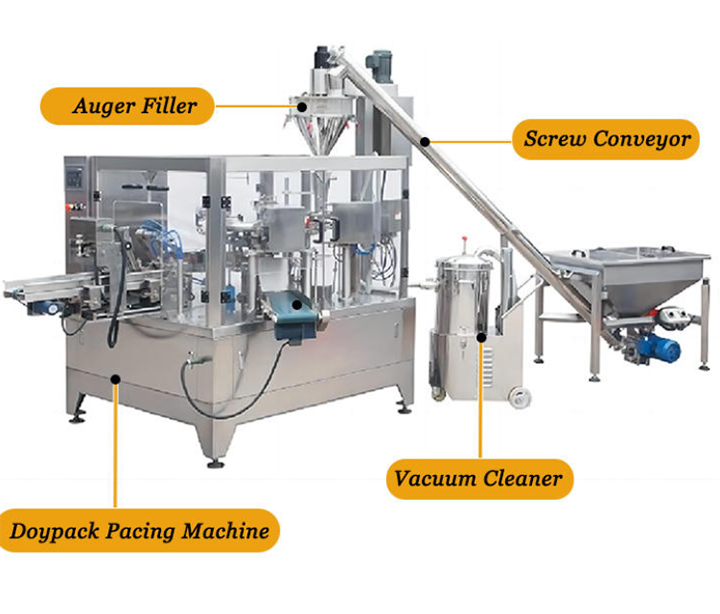

The Fully Automatic Small Bag Powder Packaging Machine consists of an automatic film feeding mechanism, a metering screw filler, a bag forming unit, longitudinal and transverse sealing mechanisms, and a slitting device. The roll of film is automatically drawn into the bag forming unit and folded into a cylindrical shape. The longitudinal sealing mechanism seals the back seam. The powder material is quantitatively filled into the film cylinder through a high-precision metering screw. Subsequently, the transverse heat-sealing mechanism simultaneously seals the top and bottom of the small bag below the filling section, forming an independent packaging unit and cutting it off for output. The entire process is continuously cyclical under PLC control, achieving fully automated operation from powder metering to sealing into bags.

What are the benefits of a Fully Automatic Small Bag Powder Packaging Machine?

A Fully Automatic Small Bag Powder Packaging Machine can achieve 24-hour continuous automated production, saving significant labor costs and reducing errors and contamination risks that may result from manual operation. Small bag packaging meets the consumer market's demand for small quantities, single use, portability, and accurate metering, and facilitates product distribution and storage, enhancing user experience and product image. For powders that are prone to dust generation, moisture absorption, electrostatic adsorption, and significant variations in flowability, vacuum or vibration-assisted feeding devices and electrostatic eliminators are designed. A special spiral design can address bridging and flow interruption issues, ensuring smooth filling and accurate metering.

Fully Automatic Small Bag Powder Packaging Machine Price

The price of a basic Fully Automatic Small Bag Powder Packaging Machine typically ranges from $5,000 to $9,000. Its packaging speed is approximately 40-80 bags per minute, automating bag making, screw metering and filling, sealing, and coding. This model is suitable for conventional powder products such as seasoning powders and instant powders where speed is not critical.

The price range for a rotary packaging line with an integrated multi-head computerized weighing system is approximately $10,000 to $20,000. Its packaging speed can reach 80-150 bags per minute, with extremely high metering accuracy. It features simultaneous multi-hopper weighing optimization, touchscreen control, and integration with front-end and back-end equipment, making it suitable for packaging high-value-added products such as nutritional powders, milk powder, and coffee.

Case Study: Fully Automatic Small Bag Powder Packaging Machine

A local specialty snack brand uses a Fully Automatic Small Bag Powder Packaging Machine to pre-package its secret-recipe chili powder, spice powder, and other ingredients into 5-20 gram packets, which are then included as complimentary seasoning packets or sold as individual items. The fully automated production line achieves high-precision filling and sealing, ensuring authentic flavor and hygiene, improving production capacity and packaging consistency, and meeting the needs of bulk supply.

A traditional Chinese medicine cooperative uses a Fully Automatic Small Bag Powder Packaging Machine to package its processed Poria cocos powder, yam powder, and other health-promoting ingredients into convenient 10-50 gram packets. The equipment overcomes the slight moisture absorption and scattering characteristics of the materials, completing a series of processes including metering, bag making, filling, sealing, and coding. This achieves product standardization and makes it convenient for consumers to take the correct amount.

The Fully Automatic Small Bag Powder Packaging Machine can be used for packaging materials such as milk powder, coffee powder, seasonings, protein powder, pharmaceutical powder, pastes, fertilizers, chemical auxiliaries, pigments, seed powders, and pesticide powders. Machrise, the manufacturer, offers standardized models and non-standard customized options to meet the packaging needs of powdered materials requiring full automation and small packaging sizes.