Automatic Packaging Machine With Weighing

The automatic weighing and packaging machine is an intelligent device that integrates metering, filling and sealing, and is suitable for quantitative packaging of granules, powders, flakes and other materials. The weighing range is 0.2kg to 50kg, the accuracy is ±0.2% to ±0.5%, and the maximum speed can reach 40 bags/minute. Weighing range: 0.1-50kg Accuracy: ±0.2% Packaging speed: 10-60 bags/minute Applicable bag types: Back-seal/Three-side seal

What is an Automatic Packaging Machine with Weighing?

Automatic Packaging Machine With Weighing accurately weighs materials and automatically completes packaging. It uses a high-precision sensor to measure material weight in real time. Combined with PLC or microprocessor control, it automates filling, sealing, and coding operations. It is suitable for packaging a variety of product forms, including granules, powders, and liquids.

The weighing range of an Automatic Packaging Machine with Weighing is typically 5g-5kg or 10g-50kg, with an accuracy of ±0.1%-±1%, ensuring consistent weight for each bag. It supports a variety of packaging materials, including composite film, PE, and aluminum foil, and is suitable for bag types such as stand-up pouches, back-seal bags, and three-side-seal bags. The packaging speed can be adjusted based on material characteristics and bag type. Standard models offer a speed of 20 to 120 bags per minute, while high-speed models can reach over 200 bags per minute. The packaging process automatically completes feeding, weighing, bag clamping, and sealing, offering high efficiency, precise accuracy, ease of operation, and stable operation, significantly improving production efficiency.

Automatic Packaging Machine with Weighing Parameters

| Model | ZV-420 | ZV-520 | ZV-720 |

| Film Width | Max.420mm | Max.520mm | Max.720mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm |

| Roll Diameter | Max.320mm | Max.320mm | Max.320mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

|

Packing Speed (Each packing machine) |

5-60bag/min | 5-60bag/min | 5-55bag/min |

| Power | 220V 50/60Hz 2KW | 220V 50/60Hz 3KW | 220V 50/60Hz 3KW |

| Machine Size(L*W*H) | 1217*1015*1343mm | 1488*1080*1490mm | 1780*1350*2050mm |

| Machine Weight | About 650kg | About 680kg | About 750kg |

| Option Device |

Two synchronous belt device, air filling device, angle fold device, automatic rectifying device, hole-punching device, link bag device. |

||

What are the types of automatic packaging machine with weighing?

Automatic packaging machine with weighing can be categorized into two main types based on their structural design: vertical and horizontal. Vertical models save space and are suitable for small packages, high-speed processing, and materials with good flowability. Horizontal machines can handle complex shapes (such as bottles and large bags) and are suitable for integration into back-end production lines.

Vertical Automatic Packaging Machines with Weighing can be categorized into several types based on material characteristics. Vertical spiral weighing packaging machines are primarily used for powdered or fine-grained materials, such as coffee powder. They achieve high-precision quantitative filling through the rotation of a screw and are suitable for applications prone to dust generation. Vertical gravimetric weighing packaging machines rely on the material's own weight to complete metering, featuring a simple structure and high speed. They are suitable for granular or flake materials with good fluidity, such as rice, seeds, and potato chips. Vertical liquid weighing packaging machines are designed for liquids or pastes, such as sauces, oils, and detergents. They utilize flow valves or pump control systems with anti-drip devices to ensure cleanliness and accuracy. Vertical multi-head weighing packaging machines are primarily used for irregular granular materials, such as frozen foods. They utilize multiple weighing heads for combined metering, achieving higher precision and packaging efficiency.

Horizontal automatic packaging machines with weighing are often used for products that require horizontal filling, such as bulk, bagged, or bottled. Their long conveyor belts facilitate the transport and positioning of various bag types and containers. Horizontal weighing and filling machines utilize a "weigh before filling" process and are compatible with pillow bags and four-side seal bags, making them suitable for bulk or pre-packaged foods such as bread, meat, and puffed foods. Horizontal liquid filling and weighing machines use flow meters or load cells to accurately measure liquids such as bottled beverages and barreled cooking oil, and can be seamlessly integrated with processes such as capping and labeling to improve production line efficiency. Horizontal combination weighing and packaging lines integrate weighing, sorting, and packaging, making them particularly suitable for products requiring multiple processing steps, such as vegetables and seafood, to achieve efficient and accurate automated production. For boxed or palletized goods, horizontal stretch film weighing and packaging machines can be used. They automatically apply film after weighing, facilitating logistics and warehousing while protecting the goods, meeting the comprehensive packaging needs of different products and processes.

How much does Automatic Packaging Machine with Weighing cost?

The following approximate price range for Automatic Packaging Machine with Weighing is for reference: Basic semi-automatic machines range from $2,000 to $7,000, suitable for small and medium-sized production operations. They require manual loading and typically have a weighing accuracy of ±1-5g. Fully automatic mid-range models range from $7,000 to $10,000, offering automatic weighing accuracy of ±0.1-1g and a relatively fast packaging speed of 20-60 packages/minute. They are suitable for industries such as food and chemicals. High-end intelligent production lines range from $10,000 to $15,000, featuring high accuracy of ±0.01g and a speed of 100+ packages/minute. They also feature integrated PLC control and data traceability, making them suitable for large-scale production.

What are the advantages of an Automatic Packaging Machine with Weighing?

Combining intelligence, high precision, and multifunctionality, the Automatic Packaging Machine with Weighing provides a powerful guarantee for efficient, stable, and cost-effective packaging production. It utilizes imported sensors and intelligent algorithm control, delivering high accuracy and stability, minimizing weighing errors and maintaining stable performance. Its user-friendly touchscreen interface with visual parameter settings makes it easy to learn and use, reducing labor training costs. Its high compatibility accommodates a variety of bag types and materials, and supports customized designs to meet diverse process requirements. Its high degree of automation allows it to automatically perform bagging, weighing, filling, and sealing, effectively improving production efficiency.

Automatic Packaging Machine with Weighing Packaging Sample Display

What are the applications of Automatic Packaging Machine with Weighing?

Automatic Packaging Machine with Weighing plays a key role in various industries. In the food industry, it's used for rapid packaging of products such as rice, sugar, nuts, dried fruit, and biscuits. In the chemical industry, it's suitable for accurately measuring materials such as additives, granular fertilizers, calcium carbonate, and resin powder. In the feed and agricultural product processing sector, it can efficiently weigh and package feed pellets, livestock premixes, grains, and seeds. In the pharmaceutical industry, some models can also be used to automatically seal small packages of materials such as herbal granules and solid beverages.

How does Automatic Packaging Machine With Weighing work?

The Automatic Packaging Machine with Weighing operates as follows: After products enter the machine via a conveyor belt or hopper, a high-precision load cell monitors their weight in real time. The system then controls dual-speed feeding based on preset values: a fast coarse feed and a slow fine feed to ensure accuracy. When the weight reaches the target, the material door automatically closes, completing dynamic weighing. The product is then filled into pre-positioned bags, and sealing and coding processes are completed simultaneously. The entire process is coordinated by a PLC control system.

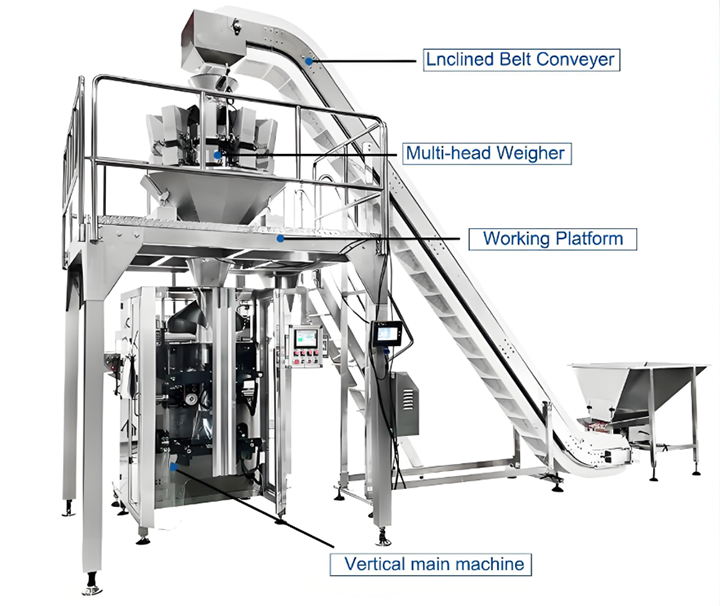

What are the structural components of Automatic Packaging Machine with Weighing?

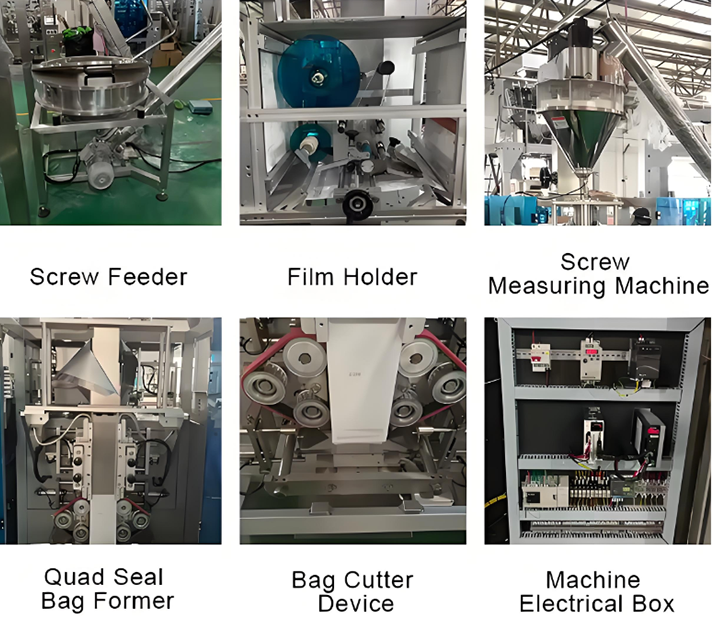

Automatic packaging machines with weighing consist of several key components: a feeding system equipped with a hopper, vibrating feeder, or screw feeder, which evenly conveys materials to a weighing unit; a weighing system employing electronic load cells and a control module for high-precision weighing; a packaging system using a bag-making machine or pre-made bag clamping mechanism to pack the weighed materials into bags; a sealing device using heat or cold seals to ensure a tight seal; a conveyor system using conveyor belts or turntables to transport bags between process steps; a control system using a PLC and touch screen for automated control, parameter setting, and data logging; and a frame and protective devices to support various components and ensure safe operation.

Automatic Packaging Machine with Weighing Industrial Process

The industrial process of an automatic packaging machine with weighing can generally be divided into the following main stages. Each stage may vary slightly depending on the industry, such as food, chemical, or hardware, and the specific model, but the core steps are similar:

Material Supply: Materials are transported from upstream equipment (such as mixers and grinders) to the packaging machine's storage silo via a vibrating feeder, screw conveyor, belt conveyor, or gravity feed system. The silo is equipped with a level sensor to ensure a continuous supply of material and prevent material shortages or overflows.

Weighing and Metering: The core equipment is a high-precision load cell (such as a strain gauge or electromagnetic force compensation type), operating in two modes: net and gross. Net weighing involves weighing the material directly in the weighing hopper, stopping feeding when the target value is reached; gross weighing involves weighing both the material and the packaging container (such as a bag or can). Accuracy typically reaches ±0.1% to ±0.5%. High-speed machines utilize multi-head combination weighers (such as 14-head computer combination weighers) to improve efficiency.

Packaging (flexible packaging only): Bag-making machines utilize roll film (such as PE/PP composite film) folded into bags by a former and heat-sealed at the bottom. Pre-made bagging machines use a robotic arm to grasp and open pre-made bags (such as paper or aluminum foil bags).

Filling: Various filling methods are available, including gravity feeding for granules and powders (such as rice and milk powder); spiral filling for viscous materials (such as sauces and oils); and vibration-assisted filling for easily agglomerated materials (such as sugar and additives). They also feature dust-proof designs and are equipped with vacuum ports or nitrogen flushing systems (e.g., in the pharmaceutical and lithium battery material sectors).

Sealing: Heat-sealing technology is suitable for plastic films, with temperature control to prevent burn-through. Woven bags (e.g., fertilizer) are sewn using industrial sewing machines. Metal cans (e.g., paint) require crimping and are sealed using crimping technology. Additional features such as nitrogen filling for freshness preservation and vacuum sealing are also available (e.g., for coffee and meat packaging).

Labeling and Coding: Information such as the production date, batch number, and barcode are added using an inkjet printer or labeler, with vision systems verifying label placement and content accuracy.

Product Output: Packages are transported to the next station (e.g., case packer or palletizer) via a conveyor belt, roller line, or robotic arm. A rejection system is also included to automatically reject packages that fail weight requirements or have incorrect labels.