Automatic Spice Powder Packing Machine

Automatic Spice Powder Packing Machine is a device that can automatically complete the measurement, filling and sealing process of spices. This device is suitable for packaging various spice products with a weight range of 5g-1kg, and the price ranges from US$2,500 to US$15,000.

Packaging speed: about 15 to 90 bags/minute

Packing range: 10g to 1kg/1kg to 2kg/5kg to 10kg

Packaging material: any heat-sealable composite film

Dimensions: 2100*700*1690mm

Weight: 700kg

Packaging size: (length) 100 to 300mm. (Film width) 220 to 500mm

Sealing type: center constant temperature seal

What is Automatic Spice Powder Packing Machine?

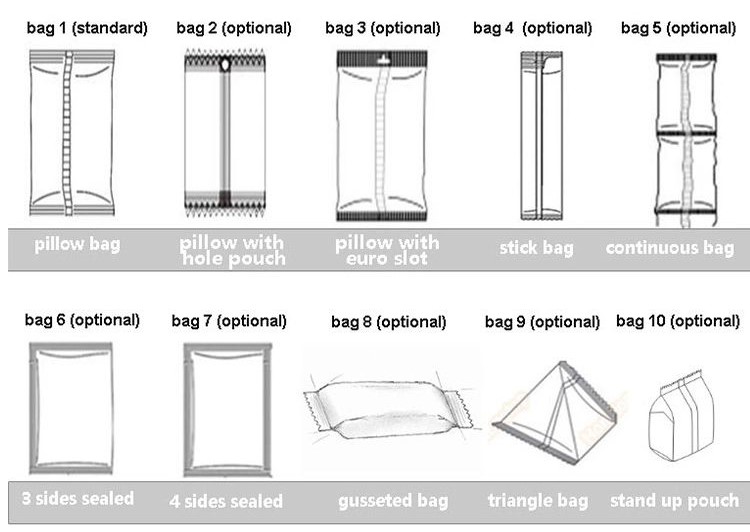

Automatic Spice Powder Packing Machine is a device that can automatically complete the processes of spice metering, filling, and sealing. According to the spice form and production requirements, the current mainstream Automatic Spice Powder Packing Machine can be divided into two categories: powder packaging type and granule packaging type. In terms of specifications, the equipment is suitable for various spice products with a packaging weight range of 5g-1kg, and the common packaging output is 30-60 bags/minute (depending on the material and bag type). The equipment supports back sealing, three-side sealing, four-side sealing and gusseted bags to meet various sealing and packaging needs.

What are the types of Automatic Spice Powder Packing Machine?

Automatic Spice Powder Packing Machine can be divided into five types according to function, packaging form and applicable scenarios:

Vertical packaging machine: It adopts roll film automatic bag making, suitable for 5g-1kg small-size packaging, such as pepper powder, curry powder, etc. It is characterized by compact structure, convenient material change, and suitable for high-precision filling (error ±0.1g).

Pillow packaging machine: It is suitable for 1kg-10kg medium and large packaging through heat sealing, with strong sealing, and can add nitrogen filling or desiccant function, which is used for batch production of chili powder, cumin powder, etc.

Premade bag packaging machine: manual or mechanical glove bag, using premade aluminum foil bag or composite film bag, with exquisite appearance, suitable for high-end condiments or gift packaging, but slow speed (20-40 bags/minute).

Semi-automatic model: requires manual intervention for loading or placing bags, the price is about $1,400-7,000, suitable for start-ups.

Fully automatic model: equipped with servo motor and PLC control, automatically completes metering, filling, sealing, and coding, with an efficiency of up to 60120 bags/minute, but the cost is higher (about $7,000-42,000).

Automatic Spice Powder Packing Machine Price Range

Common Automatic Spice Powder Packing Machines vary greatly in model, output and function. The following is a specific quotation reference:

DXDF-60C: Suitable for 1-50g small bag packaging, output of about 30-60 bags/minute, price of about US$2500-4000;

DXDF-100B: Suitable for 50-100g packaging, using screw metering system, output of 40-70 bags/minute, price of about US$5000-8000;

DXDF-500E: Suitable for 100-500g packaging, with PLC touch control, output of 30-50 bags/minute, price of US$8000-12000;

DXDF-1000L: Fully automatic high-speed type, suitable for 500g-1kg packaging, output of up to 20-40 bags/minute, suitable for industrial production lines, price of US$12000-25000.

Automatic Spice Powder Packing Machine Details

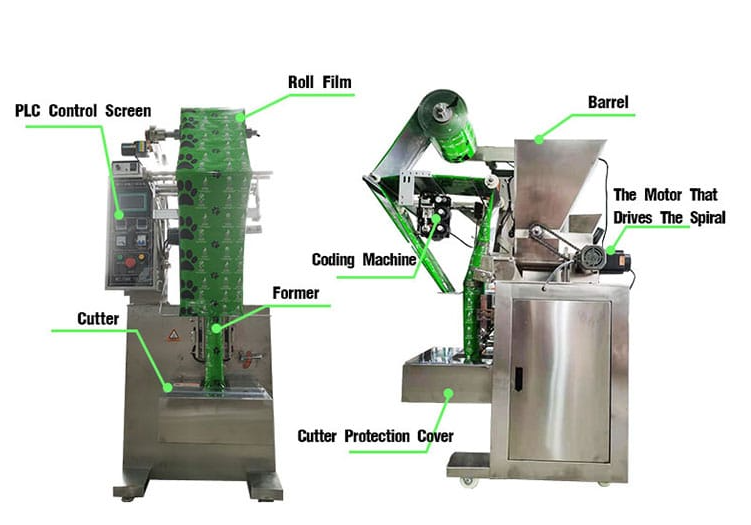

Automatic Spice Powder Packing Machine mainly consists of two parts: PLC control panel and encoder. The PLC control panel contains four core components: the cutting device is responsible for precise cutting of film materials; the rotating protective cover provides safety for the operation of the equipment; the guide roller is used for the smooth transmission of the film; and the spiral drive motor provides the power source for the entire system. The encoder part is equipped with a forming device for the shaping of the film, and is also equipped with a spiral drive motor to ensure the synchronous operation of the transmission system.

What are the sealing types of Automatic Spice Powder Packing Machine?

In order to meet the different market requirements for packaging aesthetics and sealing, Automatic Spice Powder Packing Machine supports a variety of sealing types, including:

Back seal (middle seal): simple structure, high heat sealing efficiency, suitable for small bag packaging of 10g-500g specifications, the average packaging speed can reach 30-60 bags/minute, which is one of the most common forms on the market. The equipment price is relatively low, suitable for small and medium-sized enterprises or mass production factories.

Three-side seal: Three-side seal, excellent sealing, suitable for fine powder spices, high-end seasoning packaging, can effectively prevent moisture and odor, and improve the packaging grade. Although the equipment structure is slightly complex, the packaging precision is high, suitable for brands pursuing quality. The corresponding model price is between $4,000–$7,000.

Four-side seal: The edges are sealed all around, the bag shape is symmetrical and flat, the appearance is professional, and it is widely used for export products or supermarket shelf display. Suitable for medium to large specifications (50g–1000g) packaging, the output can reach 35–65 bags/minute.

Angle bag (angle bag): The three-dimensional space is formed by the folding of the two sides, and the capacity is expanded without increasing the bag width. Suitable for large-dose granular spices packaging (such as 500g-1kg), improve stacking stability and visual volume, the equipment supports high-capacity continuous operation, and is suitable for high-speed packaging lines.

Self-supporting bag: The bottom of the bag is equipped with a support angle, which can stand independently on the shelf, especially suitable for medium and high-end compound seasonings or premixed products. This sealing form enhances the brand display power and consumer purchasing desire. It is often used in combination with zipper seals. The price is relatively high and it is suitable for supermarket channels that focus on packaging display effects.

Zipper seal: The bag mouth can be opened and closed repeatedly, which is convenient for multiple family uses and is suitable for retail spice products within 200g. The equipment generally needs to be equipped with a zipper device. Although it increases the cost, it significantly improves the user experience and is suitable for high-repurchase scenarios such as e-commerce and convenience stores.

Technical parameters of Automatic Spice Powder Packing Machine

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Working steps of Automatic Spice Powder Packing Machine

The operating process of Automatic Spice Powder Packing Machine is: automatic unloading-bag making-filling spices-heat sealing-coding printing-bag cutting and finished product output.

Automatic feeding: spices are accurately quantified through a screw feeder (powder type) or a measuring cup/vibrator (granular type);

Bag making and forming: the equipment automatically heat-seals the film material into a preset bag shape;

Filling spices: spices are accurately placed in the formed bag;

Heat sealing: heat-pressing and sealing according to the selected sealing type;

Coding and printing: an optional inkjet printer can be used to print the production date or batch number;

Bag cutting and finished product output: the formed bag is cut and discharged from the finished product delivery port, completing a complete set of packaging processes.

What are the advantages of Automatic Spice Powder Packing Machine?

Automatic Spice Powder Packing Machine not only achieves breakthroughs in operating efficiency, but also has the following advantages:

High-precision metering: using a servo-driven metering system, the error range is controlled within ±0.5 grams, ensuring that the weight of each bag of spices is highly consistent, significantly reducing the waste of raw materials.

Save labor costs: fully automatic filling-sealing integrated design, a single machine only requires one person to operate, the efficiency is 60 bags/minute, which is 3 times higher than traditional manual packaging, and the labor cost is reduced by 70%.

Beautiful and tight sealing: equipped with double-channel heat sealing mechanism and temperature PID control, the sealing strength is ≥35N/15mm, effectively blocking oxygen and moisture, and extending the shelf life of the product by more than 30%.

Strong compatibility: suitable for a variety of materials such as powders and granules, supporting back-sealing, three-side sealing and other bag types, and switching packaging specifications (50-1000g) within 5 minutes through quick-change molds.

Easy operation: 10-inch touch screen with graphical interface, supporting Chinese and English bilingual switching, reducing the risk of misoperation.

Modular design: The core components adopt plug-in structure (such as metering head, transmission module), maintenance time is shortened by 50%, and new functions can be expanded in the future through software upgrades.

Automatic Spice Powder Packing Machine Application Field

Automatic Spice Powder Packing Machine is widely used in food, medicine and chemical industries, significantly improving packaging efficiency and accuracy. Specific applications include:

Food industry

Seasoning production: packaging chili powder, curry powder, five-spice powder, etc., to meet the needs of bagging or canning of different specifications (such as 5g-1kg).

Instant drinks: quantitative packaging of milk tea powder and coffee powder to ensure sealing and moisture-proof.

Healthy food: automated packaging of protein powder and meal replacement powder to reduce the risk of artificial contamination.

Medicine and health products

Chinese medicine powder: accurate measurement of Panax notoginseng powder and Ganoderma lucidum powder (error ±0.1g), in line with GMP standards.

Powdered medicines: moisture-proof aluminum foil packaging of Isatis Root Granules to extend shelf life.

Chemicals and daily chemicals

Flavors and spices: dust-free packaging of industrial flavor powder to avoid cross contamination.

Detergent powder: automatic filling of washing powder and disinfectant powder, supporting large-capacity (10–50kg) packaging.

Other fields

Pet food: hygienic packaging of nutritional supplement powder.

Agriculture: packaging of seed coating agents and trace fertilizers.