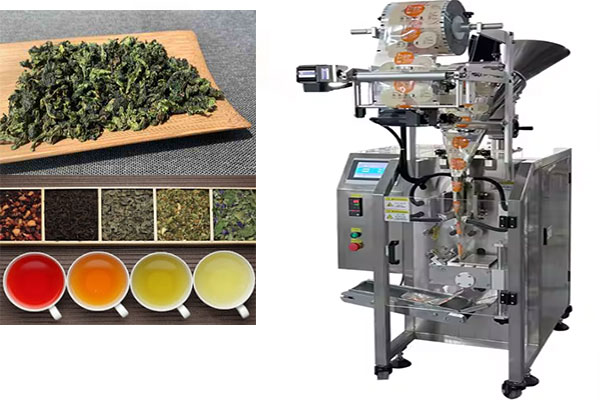

Fully Automatic Vertical Molding Soft Candy Packaging Machine

Thursday December-18 2025 17:58:08

The Fully Automatic Vertical Molding Soft Candy Packaging Machine fully automates the molding, metering, cutting, and packaging of soft candies. The machine's production speed ranges from 60 to 120 packs per minute, depending on the packaging size and configuration. Packaging dimensions are typically between 50 mm and 200 mm in length and 30 mm and 120 mm in width, catering to needs ranging from mini soft candies to standard bags. The control system uses a PLC and a human-machine interface touchscreen for parameter setting and operational status monitoring. The automatic metering unit usually employs a servo-driven combination scale or volumetric measuring cup to ensure consistent weight across each bag. Sealing methods typically include heat sealing or cold sealing, with the appropriate sealing process selected based on the packaging material.

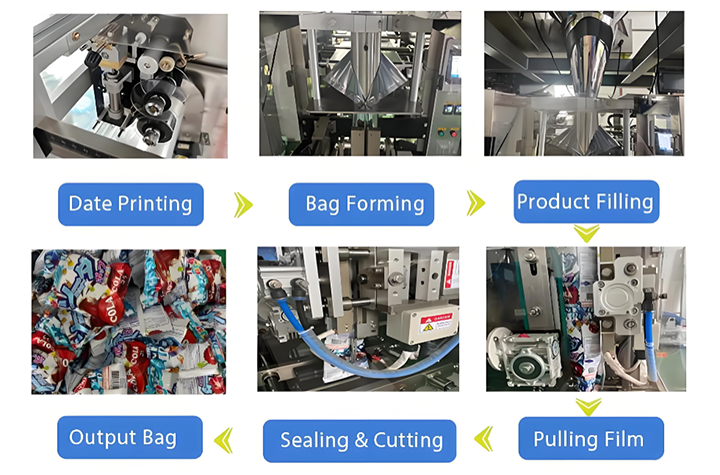

How does the Fully Automatic Vertical Molding Soft Candy Packaging Machine work?

The soft candies enter the hopper of the Fully Automatic Vertical Molding Soft Candy Packaging Machine, where the automatic metering device dispenses them into packaging bags according to a predetermined weight or quantity. The packaging bags are made from roll film or sheet material, stretched and shaped by the machine to wrap the gummy candy product. After entering the cutting stage, the equipment cuts the product to the set length or quantity, and simultaneously seals it using heat-sealing or cold-sealing technology, forming individual complete packaging units.

Functions of the Fully Automatic Vertical Molding Soft Candy Packaging Machine

The Fully Automatic Vertical Molding Soft Candy Packaging Machine employs a specially designed anti-jamming metering system to ensure packaging accuracy, addressing the potential for slight adhesion and irregular shapes of the gummy candies. The material conveying and discharge channels are smoothed to reduce wear on the gummy candy surface and maintain product appearance. It can produce various bag types, including back-seal bags, three-side seal bags, and four-side seal bags, and easily integrates additional functions such as perforation and easy-tear opening. It supports heat sealing or cold sealing and is suitable for various packaging materials. The system can monitor sealing temperature, pressure, film tension, and fault points in real time, and has automatic correction and alarm shutdown capabilities, ensuring production stability and packaging sealing.

Advantages of the Fully Automatic Vertical Molding Soft Candy Packaging Machine

The Fully Automatic Vertical Molding Soft Candy Packaging Machine achieves fully automated continuous production from raw material feeding, molding, cutting, to packaging, improving production efficiency. Its vertical design saves space compared to horizontal machines. Through a servo control system, the machine can adapt to various shapes and sizes of soft candies and can stably handle soft, easily sticky candies. It also supports integrated molding, metering, cutting, and sealing operations. Small fully automatic vertical machines and fully automatic multi-head models are available to meet the packaging volume needs of different manufacturers.

Applications of the Fully Automatic Vertical Molding Soft Candy Packaging Machine

The Fully Automatic Vertical Molding Soft Candy Packaging Machine is used for packaging gelatin soft candies, fruit juice soft candies, gummy bears, chewy gummies, milk-flavored soft candies, compound flavored soft candies, baking decoration soft candies, and certain types of candied fruit or preserves. It is widely used by confectionery manufacturers, small processing enterprises, and export companies. Whether for promotional products requiring individual packaging or regular multi-packs, this machine can adapt to various needs through quick molder changes and parameter adjustments.

Fully Automatic Vertical Molding Soft Candy Packaging Machine Suppliers

Several suppliers worldwide offer Fully Automatic Vertical Molding Soft Candy Packaging Machines. European and Japanese manufacturers possess mature technology in automation and control systems, while Chinese manufacturers have advantages in price and service. For example, the Chinese manufacturer Machrise provides customized equipment, installation, commissioning, and after-sales service at competitive prices.

The price of a Fully Automatic Vertical Molding Soft Candy Packaging Machine varies depending on factors such as configuration, level of automation, and speed, typically ranging from $5,000 to $15,000. Commonly used packaging materials include OPP, CPP, PET, and composite films, with the most suitable material selected based on the type of candy. This equipment replaces semi-automatic or manual packaging, improving candy packaging efficiency. The machine can be combined with labeling machines, case packing machines, and other systems to form an assembly line, from packaging film rolls to formed packaging bags and then to the completion of the entire core process of packaging a single product.