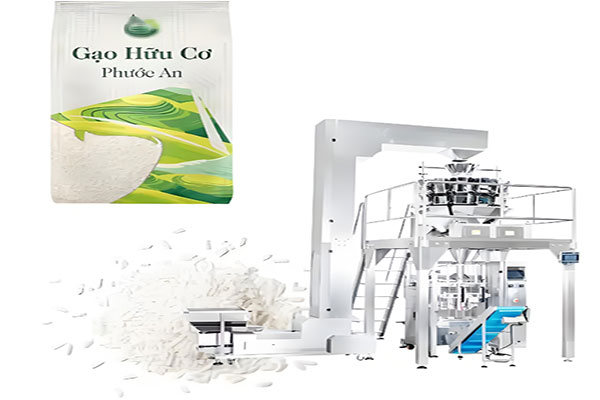

Automatic Rice Pouch Packing Machine

Automatic Rice Pouch Packing Machine are categorized by structure and degree of automation, including horizontal and feeder-type models, to suit different production scenarios. Typical equipment has a packaging capacity of 300 to 1200 bags per hour,Prices range from $2,800 to $35,000. Production Capacity: 600-1200 bags/hour

Weighing Range: 1-10 kg/bag

Accuracy: ±5 grams

Material: 304 stainless steel

Sealing Method: Heat seal or seam available

Applicable Bag Types: Back seal or three-side seal

What is an Automatic Rice Pouch Packing Machine?

Automatic Rice Pouch Packing Machine are categorized by structure and degree of automation, including horizontal and feeder-type models, to suit different production scenarios. Typical equipment has a packaging capacity of 300 to 1200 bags per hour, covering a wide range of production needs, from small processing sites to large grain distribution centers. The entire machine typically consists of an elevator, weighing system, bag-making unit, bag-sealing and bag-cutting unit, and a finished product conveyor. These components work together to automate the entire process, from material transport, automatic weighing, packaging, and finished product delivery. They offer ease of operation, high efficiency, and robust stability.

Rice primarily includes indica, japonica, and glutinous rice, and different varieties vary in grain shape, length, and moisture content. Indica rice grains are long and dry, while japonica rice grains are short and plump. Glutinous rice is high in amylopectin and has strong viscosity. Material characteristics include granularity, brittleness, and good flowability, but it is prone to clumping due to humidity. It needs to be moisture- and insect-proof, and weighing accuracy and drop height must be controlled during packaging to minimize breakage.

What are the advantages of the Automatic Rice Pouch Packing Machine?

The Automatic Rice Pouch Packing Machine offers many advantages, including efficient and fast packaging, precise metering to reduce losses, flexible adaptation to diverse needs, improved product appearance and competitiveness, reduced labor costs and workload, easy operation and maintenance, energy conservation, environmental sustainability, and adaptability and multifunctional expansion.

Efficient Production and Fast Packaging: The machine automates the metering, bag making, filling, sealing, and cutting processes, achieving a packaging speed of 30-60 bags per minute. It supports continuous operation, shortens production cycles, and meets large-scale production needs.

Precise Measuring and Reduced Loss: A high-precision electronic scale or linear weighing system controls weight errors within ±0.2%-1%, avoiding material waste and customer complaints. Automated operation reduces human contact, lowers contamination risks, and ensures hygiene and safety.

Flexible Adaptability to Diverse Needs: Supports a variety of bag types, including pillow bags, stand-up pouches, and zipper bags. Compatible with materials such as plastic composite film, paper bags, and non-woven fabrics. Customizable sizes from 1 to 50 kg are available. Some models feature secondary packaging, expanding application scenarios.

Enhanced Product Appearance and Competitiveness: The packaging is neatly presented and tightly sealed, and can be printed with the production date, batch number, and QR code, enhancing traceability and brand identity, boosting consumer trust.

Reduced Labor Costs and Intensity: One machine can replace 3-5 workers, requiring only a small number of personnel for operation monitoring, significantly reducing labor reliance and significantly reducing labor costs over the long term.

Easy Operation and Convenient Maintenance: The PLC control system and color touchscreen make parameter settings intuitive and easy to understand, and fault alarms quickly identify problems. The modular design facilitates cleaning and component replacement, resulting in low maintenance costs and a long lifespan.

Adaptable and Versatile: Compatible with granular materials such as beans, seeds, sugar, and salt, enabling a single machine for multiple uses. Optional components such as vacuum packaging and nitrogen filling devices can be added to meet special requirements such as moisture protection and freshness preservation, thereby improving equipment utilization.

Automatic Rice Pouch Packing Machine Parameters

| Model | Weighing Extent(KG) | Packaging Error(F. S) | Packaging Speed(Bags/h) | Dimension(mm) |

| DCS5 | 1-5 | 0.1% | 320 | 2345*620*710 |

| DCS50 | 15-50 | 0.1% | 320 | 710*620*2358 |

| DCS50H | 5-50 | 0.1% | 600 | 710*620*2358 |

| DCS100 | 100 | 0.1% | 240 | 990*830*2250 |

Automatic Rice Pouch Packing Machine Price

Automatic Rice Pouch Packing Machine prices range from approximately US$2,800 to US$35,000, depending on factors such as machine features, configuration, production capacity, and brand. The following are examples of prices for different machine types and configurations:

Basic Models: These machines typically provide basic automatic weighing, filling, and sealing functions and are suitable for small-scale production or businesses with limited budgets. For example, some linear weighing and packaging machines with two or four weighing systems cost approximately US$2,800 to US$5,500.

Mid-Range Models: These machines add more automation and intelligence to basic functions, such as a standalone color touchscreen, high-precision weighing system, and support for multiple bag formats. These machines are suitable for medium-sized production needs and offer higher production efficiency and packaging quality. For example, some fully automatic 1kg to 5kg rice packaging machines feature automated bag making, weighing, filling, sealing, and printing functions, with prices ranging from approximately $8,000 to $18,000.

High-end models are typically highly automated and intelligent, supporting a variety of packaging materials and bag types, and capable of meeting large-scale, high-efficiency production needs. They may also feature more advanced control systems, more accurate weighing systems, faster packaging speeds, and enhanced after-sales service. For example, some multifunctional automatic solid/granular packaging machines support a variety of bag types and packaging materials and cost approximately $18,000 to $35,000.

Parameter Comparison of Different Types of Automatic Rice Pouch Packing Machines

Common types of automatic rice pouch packing machines include horizontal automatic packaging machines and pouch-feeding automatic packaging machines. Below is a comparison of their specific parameters. Horizontal automatic packaging machines are more suitable for small bags, with a packaging range of 0.1-5 kg and a production capacity of 600-1200 bags/hour. Air consumption is approximately 0.3 m³/min, power is 3-4.5 kW, dimensions are L2000 × W1000 × H1500 mm, and prices range from approximately US$3000-7000. They are suitable for small bags of granules/powders, such as condiments and snacks. They use roll film as packaging material, can be customized with patterns, and are cost-effective.

Pouch-feeding automatic packaging machines are suitable for medium to large bags, with a packaging range of 1-10 kg and a production capacity of 400-800 bags/hour. Air consumption is approximately 0.5 m³/min, power is 4-5.5 kW, dimensions are L1800 × W1300 × H2200 mm, and prices range from approximately US$8000-13000. They are suitable for medium to large bags, such as rice and grains, and use pre-made bags for a neat appearance.

What are the applications of the Automatic Rice Pouch Packing Machine?

Household Rice: Suitable for the retail market with small packages (1kg, 5kg, 10kg, etc.), meeting the needs of supermarkets, convenience stores, and other channels.

Commercial/Catering Rice: Provides large-capacity packaging of 20kg-50kg for medium- to large-scale restaurants, canteens, and food processing plants.

High-end rice products: Such as organic rice, fragrant rice, and germinated rice require precise metering and attractive packaging to enhance product value.

Other Granular Grains: Suitable for packaging grains (such as red beans and mung beans), cereals, animal feed, and similar materials.

Working Principle of the Automatic Rice Pouch Packing Machine

The Automatic Rice Pouch Packing Machine feeds rice via a conveyor belt into a metering device, where a load cell precisely controls the weight of each bag. After metering, the rice falls into a forming machine, where the film material is heated and sealed at the bottom to form the bag. The measured rice is then automatically poured into the bag, and the top is sealed with a heat or cold seal to ensure a tight seal. The entire machine is controlled by a PLC and uses photoelectric sensors to detect position and bag shape, ensuring speed and accuracy. It's suitable for continuous rice packaging lines, reducing manual labor and improving production efficiency.

How to Choose the Right Automatic Rice Pouch Packing Machine?

Selecting an Automatic Rice Pouch Packing Machine requires comprehensive consideration of several key factors to ensure the equipment meets production needs, maximizes investment returns, and ensures stable operation. These factors primarily include the following:

Production Capacity Requirement: Choose equipment that matches your factory's daily output or order size. For example, small processing plants can choose vertical machines, while large and medium-sized enterprises recommend high-capacity multi-head weighers.

Packing Specifications: The weight range required for daily packaging must be clearly defined to ensure the equipment operates within the standard range and avoid overloading or idling.

Budget and Return on Investment: The price of the equipment is proportional to its functionality. If your budget is limited, consider a cost-effective semi-automatic model. If efficiency is your primary goal, a fully automatic combination weighing machine should be preferred.

Site and Supporting Conditions: Equipment size, gas and power supply requirements must be compatible with existing factory conditions to avoid production delays due to insufficient supporting facilities.

In addition, selecting a manufacturer with excellent after-sales service, technical support, and guaranteed parts supply is also crucial to ensuring long-term stable operation of the equipment.