Vertical Powder Packaging Machine

Vertical Powder Packaging Machine can pack at a speed of 30 to 60 bags per minute, with a metering accuracy of up to ±1%, and is suitable for a bag width range of 60 to 200 mm. The price varies depending on the configuration and function, usually between $3,000 and $15,000. Packaging speed: 30-60 bags/minute Measuring accuracy: ±1% Bag width range: 60-200 mm Power supply specification: 220V/380V Material: Stainless steel 304

What is Vertical Powder Packaging Machine?

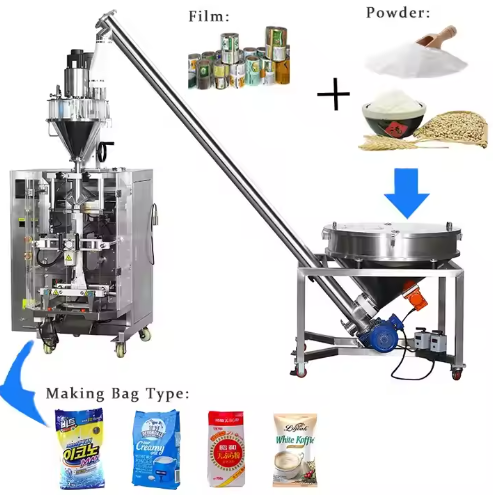

Vertical Powder Packaging Machineintegrates bag making, filling, and sealing, enabling it to quickly and accurately package powders, snacks, and small granular products into flexible pouches or containers. It can be combined with input and output equipment such as screw conveyors and belt conveyors to create a complete integrated packaging system.

The Vertical Powder Packaging Machine boasts a packaging speed of 30 to 60 bags per minute, a metering accuracy of up to ±1%, and is suitable for bag widths ranging from 60 to 200 mm. Constructed of high-quality stainless steel, the machine is durable and easy to clean. It supports 220V or 380V power supplies, ensuring stable and reliable operation. Pricing varies depending on configuration and features, typically ranging from US$3,000 to US$15,000, to meet diverse automated packaging requirements.

How do vertical machines work?

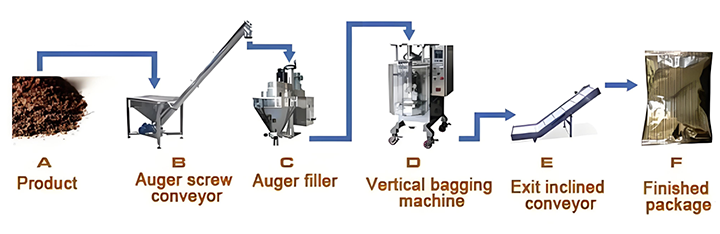

The vertical powder packaging machine's workflow is as follows: film unwinding → passing through a former to form a cylinder → longitudinal back seal → transverse bottom seal → filling → transverse top seal and cutting → finished product output.

After unwinding, the packaging film is guided through a special conical former and rolled into a cylinder. The longitudinal seam of the cylinder is then continuously heat-sealed by a longitudinal heat-sealing device. A pair of transverse sealing jaws then heat-seal the top of the cylinder to form the bottom of the next bag. They also heat-seal the top of the bag below the filled material and separate the finished bags. Simultaneously, powder, precisely metered by a screw, volumetric cup, or weighing device, falls through a discharge tube into the bottom-sealed film cylinder. Finally, the sealed finished bags are discharged and collected, completing the automated cycle.

What are the Features of Vertical Powder Packaging Machine?

Vertical Powder Packaging Machine adopts a vertical design, with a compact structure and small footprint, high integration and stable operation. Its main components include feeding system, metering device, bag making mechanism and sealing and cutting components, etc. The specific features are as follows:

The structural design adopts a modular design, which is convenient and quick to adjust. Users can flexibly adjust parameters according to the powder characteristics (such as fluidity, density, etc.) to ensure a stable and reliable packaging process. A screw conveyor is also optional, which is suitable for powders that are prone to dust or have poor fluidity, effectively improving packaging efficiency and reducing material waste. In terms of functions and performance, it supports automated operation and is equipped with touch screen control, automatic deviation correction and temperature adjustment functions, which are easy to operate. Some models adopt a modular design, which is easy to maintain and easy to clean. In terms of materials and compliance, the main material is stainless steel, which meets the hygiene standards of the food and pharmaceutical industries to ensure safety and durability.

What are the types of Vertical Powder Packaging Machine?

Vertical Powder Packaging Machine is divided into standard vertical type, spiral metering type, multi-functional combination type and vacuum powder suction type according to function, degree of automation and applicable materials:

Standard vertical powder packaging machine: compact structure, easy operation, suitable for small and medium production capacity requirements (such as 5-30 bags/minute), often used for quantitative packaging of single-specification powders, such as milk powder, seasoning powder, chemical powder and other materials with medium fluidity.

Screw metering type: through the screw conveying quantitative method, it can accurately package high-fluidity (such as starch, glucose) or low-fluidity (such as protein powder, metal powder) materials, the metering accuracy can reach ±1%, suitable for industries with strict metering requirements such as medicine and food additives, and the output is about 10-50 bags/minute.

Multifunctional combination type: integrated with automatic weighing, printing, nitrogen filling, sealing and other functions, supports customized design, suitable for production line automation, with a production capacity of 20-60 bags/minute, widely used in food, medicine, chemical and other industries, such as coffee powder, nutritional supplements and other powders that are easy to oxidize or need to be preserved.

Vacuum powder suction type: vacuuming during the packaging process, effectively preventing moisture and oxidation, suitable for high-demand materials such as pharmaceutical powders and food additives, with a production capacity of about 8-40 bags/minute, especially suitable for powder packaging that is sensitive to shelf life.

Technical parameters of Vertical Powder Packaging Machine

| VFFS -320 | VFFS-420 | VFFS-520 | VFFS-720 | |

|---|---|---|---|---|

| Packing Speed | 5-70bags/min | 5-60bags/min | 5-50bags/min | 5-40bags/min |

| Bag Length | 50-200mm | 80-300mm | 100-400mm | 100-450mm |

| Bag Width | 50-150mm | 50-200mm | 100-250mm | 100-350mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | Max.320mm |

| Filling Range | 50-800ml | 150-1200ml | 200-2000ml | 250-4000ml |

| Film Width | Max. 320mm | Max. 420mm | Max. 520mm | Max. 720mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Air Consumption | 0.3m3/min 0.65MPa | 0.3m3/min 0.65MPa | 0.4m3/min 0.65MPa | 0.4m3/min 0.65MPa |

| Voltage | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz |

| Power | 2.0kw | 2.2kw | 4kw | 4.5kw |

| Machine Dimensions | 117*82*129cm | 132*95*136cm | 149*108*149cm | 172*126*182cm |

| Machine Weight | 350kg | 550kg | 750kg | 850kg |

What is the price range of Vertical Powder Packaging Machine?

The price of Vertical Powder Packaging Machine varies depending on the configuration, brand, production capacity, and degree of automation. The price range is around US$2,500 to US$20,000. The following is a reference market price range for the machine models:

Basic standard type: about $2,500–$6,500, this model is designed for start-ups or small-volume scenarios, and is mainly economical and practical. The core functions include basic metering and filling (suitable for loose materials such as granules and powders), simple sealing (supporting common bag types such as back sealing and three-side sealing), and manual adjustment of packaging parameters (such as length and speed). Although the degree of automation is low, the compact structure and simple maintenance are suitable for customers with limited budgets or single products, such as small food factories and agricultural and sideline product processing.

Mid-to-high-end screw metering type: about $6,500–$13,000. This model is designed for high-precision metering needs and comes standard with a servo-driven screw filling system. The error can be controlled within ±0.5%, which is suitable for high-value powders such as condiments and milk powder. The functions integrate touch screen control (preset multiple formulas) and automatic deviation correction (to ensure film alignment). Some models support multi-stage nitrogen filling (extend food shelf life). Vibration leveling or vacuum modules can also be selected to further improve packaging consistency. Suitable for medium-sized production lines, such as health products, chemical raw materials, etc., balancing efficiency and cost.

Multifunctional combination/high-speed type: about $13,000–$20,000+. The high-end model is based on modular design and can flexibly integrate automatic weighing and checking (dynamic rejection of unqualified products), dust removal and static electricity removal (clean packaging environment), QR code printing (traceability system) and other functions. The high-speed model adopts multi-channel synchronous filling, with a production capacity of more than 200 packs/minute, which is suitable for large factories. Typical applications include industries with strict requirements on hygiene and efficiency such as medical devices and high-end snacks, and the price fluctuates significantly with the configuration.

How to choose a suitable Vertical Powder Packaging Machine?

When choosing a suitable Vertical Powder Packaging Machine, you need to consider a number of key factors to ensure that the equipment can meet production needs.

First of all, material properties are the core factor in selection. The fluidity, particle size, density and viscosity of different powders vary greatly, which directly affects the choice of metering method. For example, powders with good fluidity are suitable for screw metering, while powders with poor fluidity or easy agglomeration may require an electronic weighing system to ensure accuracy. For materials that are easy to absorb moisture or oxidize, the airtightness and dustproof design of the equipment must also be considered.

Secondly, production needs determine the performance configuration of the equipment. The packaging speed (such as 10-60 bags/minute) and production capacity must match the rhythm of the production line. For large-scale production, high-speed and high-stability models need to be selected, and supporting functions such as automatic bagging, lining or boxing should be considered; small-batch and multi-variety production focuses more on the ability to switch flexibly.

Third, the packaging bag type and size need to be clear. The equipment should support the target bag type (such as back-sealed bags, four-side sealed bags, self-supporting bags, etc.) and size range (such as length 50-300mm, width 30-200mm). If the specifications need to be changed frequently, modular designs that can be adjusted quickly are preferred.

Fourth, automation and operability affect long-term use efficiency. Highly automated equipment (such as automatic feeding, batch number printing, and foreign body detection) can reduce manual intervention, but it is necessary to evaluate whether the operating interface is friendly and whether maintenance is convenient. For example, touch screen control and fault self-diagnosis functions can significantly reduce downtime.

Finally, the supplier service and budget need to be balanced. Give priority to brands with mature technology and fast after-sales response to ensure spare parts supply and technical support. At the same time, compare the cost-effectiveness of different solutions to avoid sacrificing key performance or durability due to low prices.

Vertical Powder Packaging Machine Application

Vertical Powder Packaging Machine is suitable for packaging various dry powders and granular materials, such as flour, milk powder, coffee powder, laundry detergent, seasonings, grains, sugar, salt and pharmaceutical granules, etc.

What are the Vertical Powder Packaging Machine solutions?

For vertical packaging of powder materials, the Vertical Powder Packaging Machine is a core solution, integrating automated bag making, metering, filling, and sealing and cutting functions. The servo screw metering unit provides stable, controllable volumetric metering for fine powders with good flowability, offering a cost-effective solution. For products requiring extremely high precision, a multi-head computerized combination weigher is used, achieving an accuracy of ±0.1g. To further enhance efficiency and quality control, an integrated production line solution can be implemented, combining an elevator, metal detector, weight checker, and robotic palletizer to create a complete automated production line.