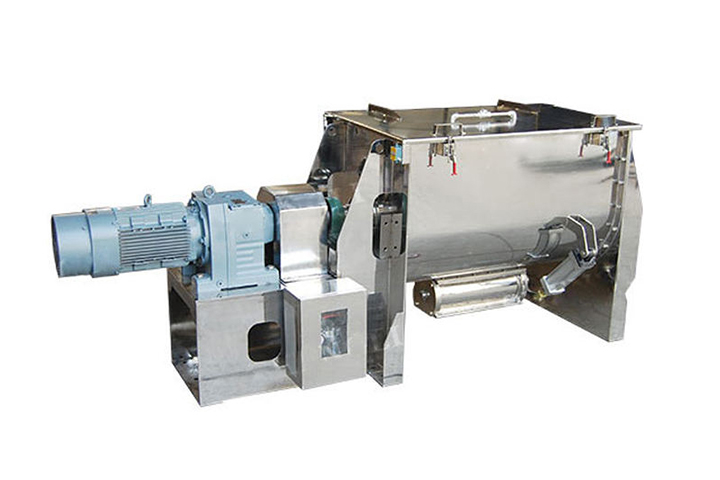

Lab-Scale Powder Ribbon Mixer Cosmetic Ingredients Blending

The lab-scale powder ribbon mixer cosmetic ingredients blending, as a laboratory reagent mixing device, not only meets the high mixing precision requirements of cosmetic raw materials, but also offers a compact design suitable for laboratory environments. This reduces R&D costs, accelerates formulation iteration, and provides reliable support for the transition from R&D to mass production. Material: 304/316 stainless steel Power: 1.1-15kW Mixing Time: 5-60 minutes Volume: Formula R&D typically requires 5-50L, while small- to medium-scale production requires 100-2000L.

What is a lab-scale powder ribbon mixer cosmetic ingredients blending?

A lab-scale powder ribbon mixer cosmetic ingredients blending is a miniaturized ribbon mixer designed specifically for laboratory or small-batch production environments. It is used to uniformly mix and disperse powdered raw materials in the cosmetics industry. This mixer is compact and flexible, simulating the mixing effects of industrial production, providing a precise mixing solution for cosmetic formula R&D and small-batch trial production.

How does a lab-scale powder ribbon mixer cosmetic ingredients blending work?

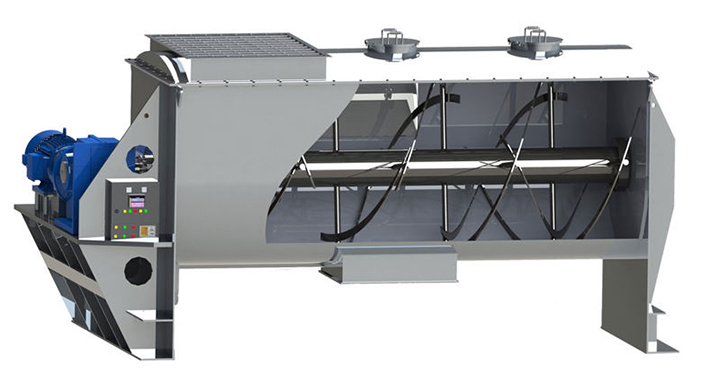

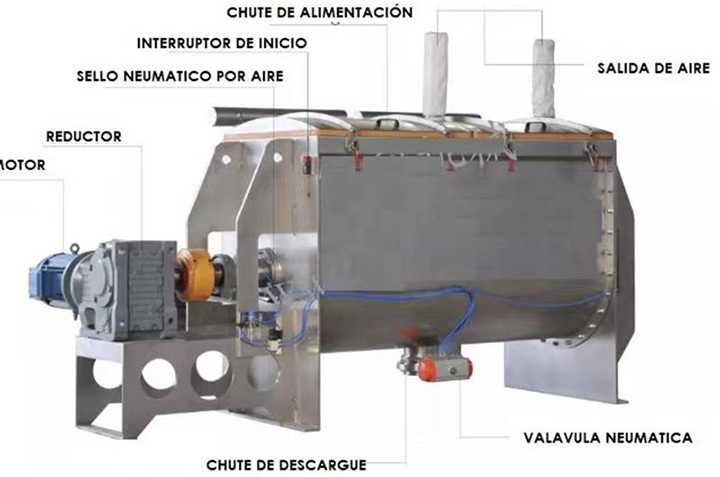

The lab-scale powder ribbon mixer cosmetic ingredients blending uses a motor and a reduction gear to drive the mixing shaft. The inner and outer double ribbons fixed to the shaft rotate synchronously in opposite directions, causing the material to circulate within the shaft. Simultaneously, the material experiences shear as it passes between the ribbons and between the ribbons and the chamber wall, achieving dispersion. As mixing progresses, the different cosmetic ingredients come into contact with each other, achieving uniform mixing.

What is the structure of the lab-scale powder ribbon mixer cosmetic ingredients blending?

Container: Made of food-grade 304 or 316 stainless steel, typically horizontal cylindrical or U-shaped.

Mixing System: Consists of the mixing shaft and inner and outer double ribbons.

Power System: The motor provides adjustable power and speed. The reduction gear reduces motor speed and increases torque.

Frame: Typically constructed of carbon steel or stainless steel, it supports the equipment.

What are the advantages of the lab-scale powder ribbon mixer cosmetic ingredients blending?

High mixing uniformity: The counter-rotating spiral design of the inner and outer double ribbons effectively eliminates powder stratification issues caused by density differences and agglomeration.

Compact Structure: The equipment typically ranges from 10-500L, with a small footprint, making it suitable for limited laboratory space.

Controllable Parameters: Equipped with a variable frequency motor and a simple control system, the speed and mixing time can be precisely adjusted.Comparative experiments optimize the mixing process, providing reliable parameter references for industrial production.

Applications of lab-scale powder ribbon mixer cosmetic ingredients blending?

Laboratory-scale powder ribbon mixers for mixing cosmetic ingredients: With precise, flexible, and safe mixing capabilities, these mixers are a key step in the transition from "lab formula" to "market product." They meet the rigorous testing needs of the R&D stage while also accommodating the practicality of small-batch production, providing reliable support for innovation and quality assurance in the cosmetics industry.

Small-batch Production: Meets market trials or customized supply needs, avoiding the costly waste of large-scale production.

Verifying Batch Stability: Multiple mixing tests verify mixing consistency before full-scale production, ensuring consistent product quality and reducing the risk of mass production.

Highly adaptable to: makeup (foundation, eye shadow, etc.), skincare (mask powder, moisturizing powder, etc.), and special functional powders (sunscreen powder, oil-control powder, etc.).

Related news

- Tablet and powder packaging machine

- Fully Automatic Small Bag Powder Packaging Machine

- Silica powder packaging machine

- Automatic Chemical Powder Filling Packing Machine

- Twin Shaft Paddle Mixer For Feed Mills

- 100kg Spice Horizontal Mixer

- Food Grade Spice Mixer

- Crushing and Mixing Machine Fertilizer Production