Smaller ribbon mixer

Suitable for small-scale pilot production, laboratory R&D, and specialized material production, this mixer mixes powders, granules, liquids, and viscous materials. Price ranges from $200 to $1000.

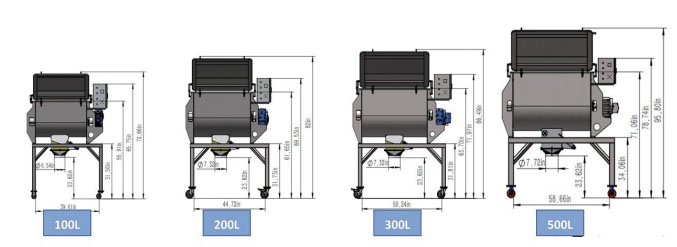

Capacities: 5L, 10L, 25L, 50L, 100L, 200L, 300L, 500L, etc.

Mixing Capacity: 5-500kg/batch

Discharge Method: Manual, pneumatic, or electric

What is a smaller ribbon mixer?

A smaller ribbon mixer is a mixer used for mixing small batches of materials, small-scale trial production, and laboratory research. Its rotating ribbon propels materials through mixing, rapidly blending them evenly within 5-10 minutes. It can be used to mix powders, powders with liquids, granular materials, and viscous materials. Capacities range from 5L to 500L. For example, a 50L mixer typically mixes 30-40L and is often used for small-volume experiments or sample preparation. A 200L mixer can mix 150-180L, making it suitable for small-scale production.

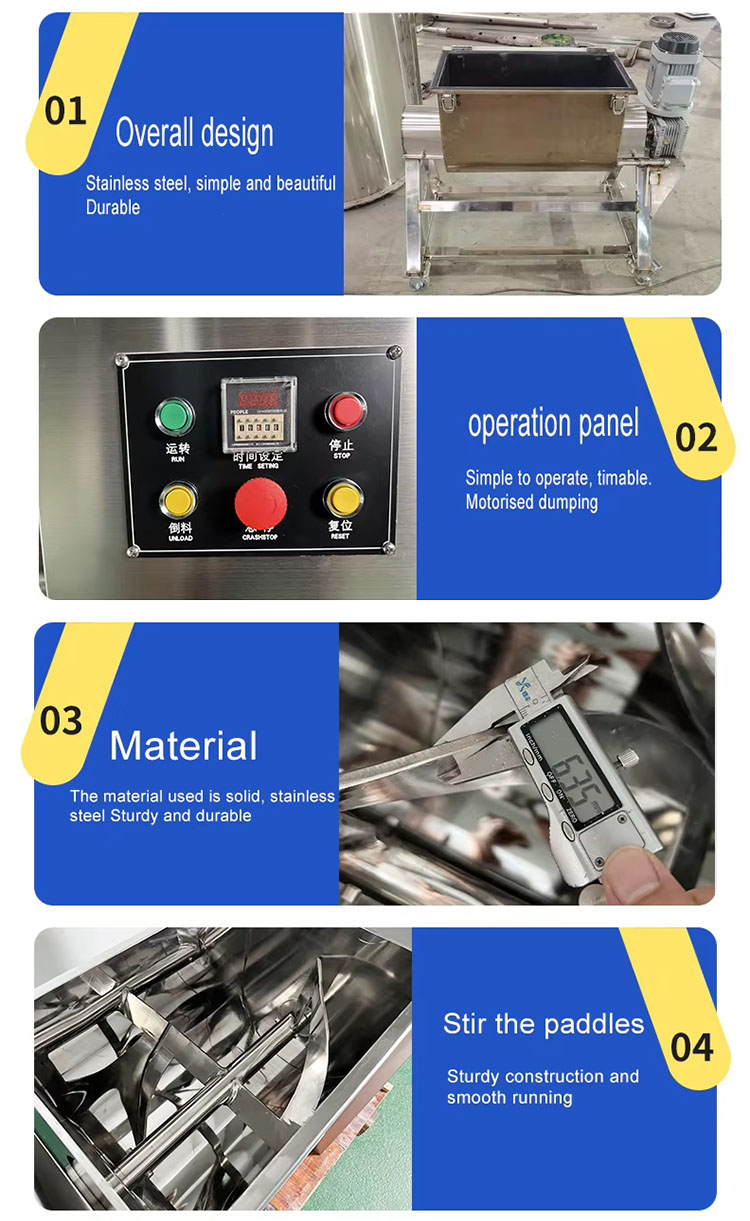

Compared to traditional mixing equipment, a smaller ribbon mixer occupies less space and is more economical. While still providing the same mixing quality, it can also handle some difficult materials that larger mixers struggle to handle. Available in carbon steel and stainless steel (depending on the material being mixed), the mixer can be customized to suit different material properties, including heating, spraying, and cooling options.

What are the advantages of a smaller ribbon mixer?

Small ribbon mixers are compact and require minimal floor space, making them ideal for small and medium-sized businesses, laboratories, and small-batch production, addressing the space constraints of larger equipment. They are also user-friendly, requiring no extensive training. A single person can easily complete the loading, mixing, and discharging processes, reducing labor costs. Compared to larger equipment, they consume significantly less power during operation, resulting in significant energy savings over the long term. Despite their small size, they deliver excellent mixing performance, achieving precise and uniform mixing, meeting the high-quality mixing requirements of small-batch production.

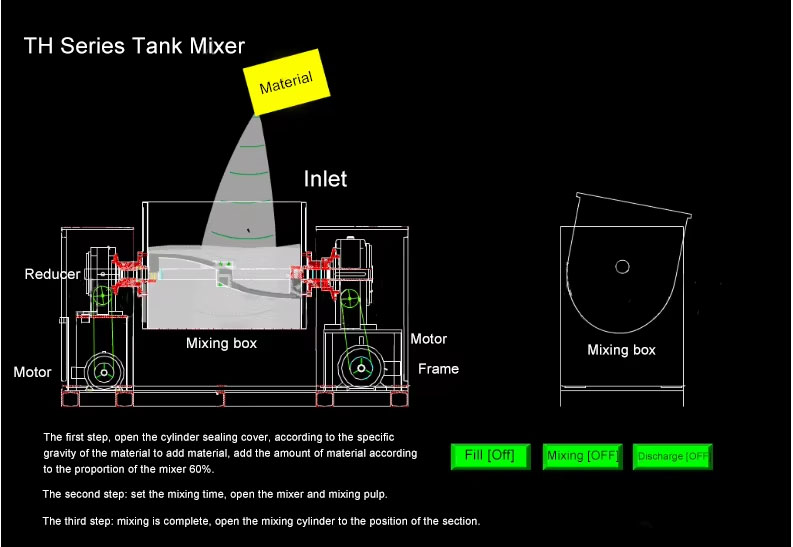

How does a small ribbon mixer work?

When a small ribbon mixer is operating, material enters the device. The outer spirals gather the material from the sides toward the center, while the inner spirals convey the material from the center to the sides. This bidirectional motion creates more eddy currents in the material flow, promoting convection circulation and shear mixing, resulting in rapid and uniform mixing in a shorter time.

Smaller ribbon mixer specifications

What are the applications of small ribbon mixers?

Smaller ribbon mixers can be used for a variety of small and medium-sized batch mixing needs. In powdered materials, it can be used to mix food ingredients such as flour, milk powder, and food additives, ensuring a uniform blend and enhancing food taste. It can also mix construction powders such as cement and lime, meeting the proportioning needs of small-scale construction projects or laboratories. It is also used in the pharmaceutical industry to mix traditional Chinese medicine powders and Western medicine excipients, ensuring precise composition. For granular materials, it can mix plastic granules and feed pellets, facilitating small-scale plastics processing or feed production. It can also handle some solid-liquid mixtures, such as small-batch preparation of coatings and adhesives, as well as sauces and pastes in the food industry. Its gentle mixing process minimizes the inherent properties of the materials, providing reliable support for small-scale production or experimental research in industries such as food, building materials, pharmaceuticals, and plastics.

Smaller ribbon mixer customer case

A food additive company needed to mix multiple nutritional supplements with widely varying ratios (up to 1:5000), and each batch produced only 200-300 kg. The previous traditional mixer suffered from uneven mixing, large residues, and difficult cleaning. After switching to the WLDH-0.5 Smaller ribbon mixer:

Mixing time was reduced from 40 minutes to 12 minutes.

Mix uniformity was significantly improved, significantly enhancing product quality and consistency.

Residue was reduced to less than 0.5%, reducing cross-contamination and material waste.

Cleaning time was reduced by 70%, improving production efficiency.