Automatic Chemical Powder Filling Packing Machine

Tuesday November-25 2025 17:36:56

Automatic Chemical Powder Filling Packing Machine offer automated filling, metering, sealing, coding, and packaging of chemical powders. For flammable, volatile, and some corrosive chemical powders, the equipment utilizes a closed conveyor system, electrostatic protection, and corrosion-resistant materials to ensure operational safety. It can also be equipped with nitrogen protection, dust removal, and explosion-proof devices.

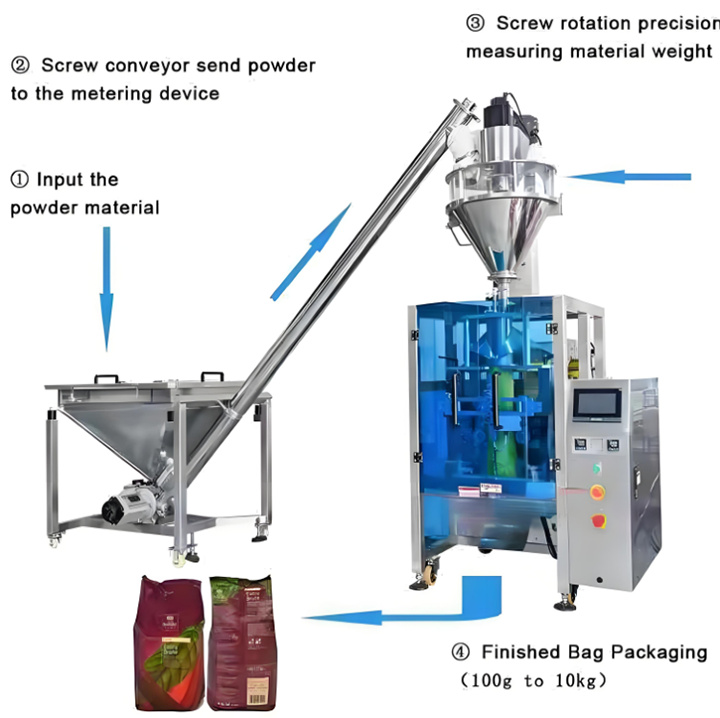

Common technologies include screw conveyors, gravity feeding, vibratory feeding, and electronic weighing. Metering accuracy is typically within ±0.5%, and processing capacity ranges from 200 to 1200 pieces per hour. Supported packaging formats include paper bags, plastic bags, aluminum foil bags, and composite material bags, with sizes customizable to customer requirements.

How does an Automatic Chemical Powder Filling Packing Machine work?

The operation of an Automatic Chemical Powder Filling Packing Machine involves conveying chemical powder through a hopper or screw feeder to the weighing system and metering chamber. Sensors trigger the filling mechanism based on a preset weight, causing the auger to rotate and push the powder into the container, while the weighing unit continuously calibrates. After filling, the equipment automatically performs heat sealing, cold sealing, or compression sealing to ensure packaging airtightness. Production date, batch number, barcode, or QR code printing can be performed simultaneously as needed. Finished products are automatically transported to the stacking area or the next process via conveyor belt. The entire process is automated, with the system monitoring weighing, filling volume, and issuing fault alarms in real time.

Features of Automatic Chemical Powder Filling Packing Machines

Automatic Chemical Powder Filling Packing Machines employ multiple filling methods, including spiral, vibratory, and gravity feeding, allowing for the selection of the optimal method for different chemical powder characteristics such as stickiness, clumping, and deliquescence. The system integrates a PLC and human-machine interface, enabling one-button start/stop, fault self-diagnosis, and remote monitoring from feeding, weighing, filling to packaging, and supports linkage with other equipment on the production line. The system uses high-precision electronic scales or sensors for rapid and accurate metering, combined with multi-stage feeding modes, controlling the error within ±0.5%. An internal pulse dust collector or vacuum adsorption device collects escaping chemical powder through negative pressure, ensuring a clean working environment and preventing powder waste. Optional features include nitrogen filling, explosion-proof protection, inkjet coding system, barcode scanning, conveyor belt linkage, and remote monitoring systems to enhance equipment adaptability.

Types of Automatic Chemical Powder Filling Packing Machines

Depending on different production needs, Automatic Chemical Powder Filling Packing Machines can be divided into spiral powder filling machines and explosion-proof and corrosion-resistant powder packaging machines.

Spiral powder filling machines are driven by servo motors, achieving packaging speeds of 200-600 bags per hour. They are suitable for three-side seal, four-side seal, back seal bags, and stand-up zipper bags. Their key feature is the use of a precisely controlled spiral drill bit for filling, achieving high-precision metering with an error within ±1%. The equipment also operates smoothly and maintains stable production capacity.

Explosion-proof and corrosion-resistant powder packaging machines utilize high-quality corrosion-resistant materials such as 316L stainless steel and PTFE for both material contact parts and the overall structure. The machine body often uses 304 stainless steel or a higher standard anti-corrosion coating. Packaging speeds range from 100-400 bags per hour. These machines are designed for packaging flammable, volatile, or highly corrosive hazardous chemical powders, maximizing production safety through explosion-proof and fully sealed structures.

Automatic Chemical Powder Filling Packing Machine Industry Application Cases

Automatic Chemical Powder Filling Packing Machines enable high-speed automatic metering and packaging of free-flowing, uniformly sized chemical powders, such as sodium sulfate and sodium carbonate. For hygroscopic and highly hygroscopic powders, such as calcium chloride and ammonium chloride, moisture-proof and airtight packaging devices are required to ensure product quality. For sticky or easily airborne powders, such as activated carbon and talc, vacuum adsorption or closed conveying is typically used to reduce dust pollution and improve safety. For chemically highly reactive powders, such as sodium persulfate and potassium dichromate, explosion-proof and anti-static designs are incorporated to ensure production safety.

Automatic Chemical Powder Filling Packing Machines use servo screw conveyors for powder metering and filling. For packaging fine chemical powders, screw-type packaging machines can be selected; for corrosive chemical powders, corrosion-resistant machine materials can be chosen. Machrise, the manufacturer, holds CE and ISO9001 certifications and can provide non-standard customization; its equipment is exported to various countries.