Powder Ribbon Mixer

The rotating ribbon blades enable rapid and uniform mixing of various powder materials, ensuring thorough integration of the various powder ingredients. Prices range from $800.00 to $6,500.00.

Mixing capacity: 100-6000 kg/time (larger sizes available on request)

Mixing time: 5-15 minutes

Blade options: Single/double ribbon, reverse ribbon

What is a Powder Ribbon Mixer?

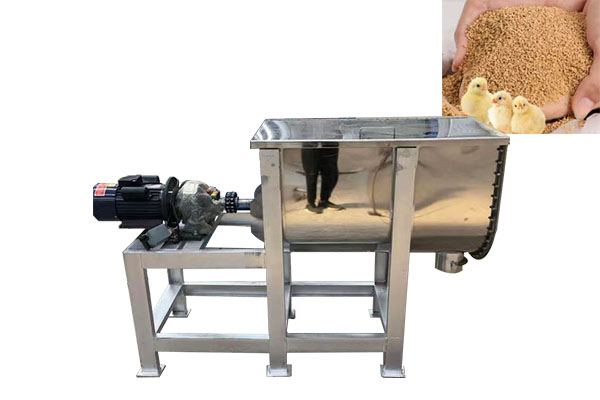

A Powder Ribbon Mixer is a mixer used to mix various powder materials. Its rotating spiral blades propel the powder back and forth, evenly mixing it. This helps break up lumps and achieve a uniform blend of different powder components. It can be used to mix a variety of non-viscous or low-viscous powders, such as flour, milk powder, soy flour, feed premix, chemical pigment powder, pharmaceutical raw powder, and cement additive powder. The mixing capacity ranges from 100 to 6,000 kg per operation, with larger sizes available upon request. The mixing time typically lasts 5 to 15 minutes.

The blades of the Powder Ribbon Mixer can be selected based on the powder material being mixed. Standard ribbons are used for general powders, ribbons with breaking teeth are used for materials prone to agglomeration, and double ribbon blades are used for powders with poor flowability. Materials available include 304 stainless steel (meets food and medical hygiene requirements) or carbon steel (suitable for general chemical and building materials applications). We also offer customized solutions for materials, products, and applications.

What types of powder ribbon mixers are there?

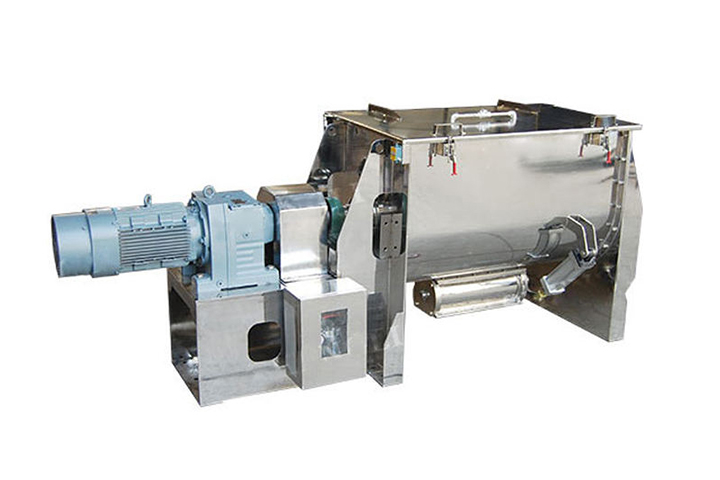

Powder ribbon mixers are primarily categorized as single-shaft and dual-shaft. Users can select the appropriate model based on the properties of the materials being mixed. If you have any questions, please contact our online customer service.

Single-shaft Powder Ribbon Mixers: Relying on a single rotating spiral ribbon to drive the material in a complex circular and axial motion, the mixing process is gentle and suitable for mixing non-sticky, fluid powders such as flour, milk powder, and base feed powder. The mixing volume typically ranges from several hundred liters to 3 cubic meters, with a mixing time typically of 5-15 minutes.

Dual-shaft Powder Ribbon Mixers: Using two counter-rotating spiral ribbons to enhance material convection and shear, the mixer achieves higher mixing efficiency and can break up slightly agglomerated materials. It is suitable for mixing chemical pigment powders, pharmaceutical premixes, and other materials. The mixing volume can reach 2-15 cubic meters, with a mixing time of 3-10 minutes, making it more suitable for medium- to large-scale production needs.

What are the advantages of a powder ribbon mixer?

The Powder Ribbon Mixer achieves high mixing uniformity and can be used to evenly mix powder materials with a ratio of 1:10,000, especially for materials with large specific gravity differences. It also boasts fast mixing speed and high efficiency, with each batch of powder materials mixing within 15 minutes, 6-10 times or more more efficient than other mixers. It has no dead spots and no residual material. Its horizontal design allows for low installation height, making it suitable for factories with height restrictions. It can also be customized to suit specific locations, such as adding a bottom wheel or extending the discharge port.

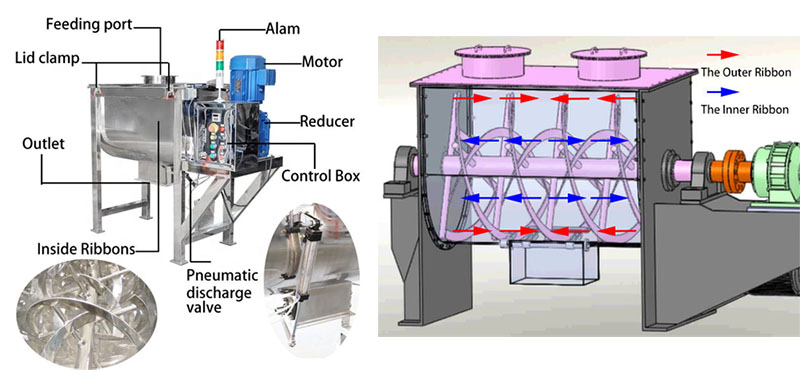

How does the Powder Ribbon Mixer work?

When the Powder Ribbon Mixer is operating, the outer spiral ribbon gathers the powder material from the sides toward the center, while the inner spiral ribbon conveys the powder material from the center to the sides, creating a strong convection motion. This creates a velocity gradient within the powder material, generating shear between the layers, causing the materials to interpenetrate, shear, and mix. Local powder particles collide and diffuse during this motion, achieving uniform distribution.

Powder Ribbon Mixer Specifications

| Model | Cylinder Volume (L) | Filling Volume (L) | Mixing Time (min) | Stirring Motor (kW) | Equipment Weight (kg) |

| WLDH-100 | 100 | 30-60 | 8-20 | 1.5-4 | 320 |

| WLDH-300 | 300 | 100-180 | 8-20 | 3-5.5 | 510 |

| WLDH-500 | 500 | 200-300 | 8-20 | 4-11 | 920 |

| WLDH-1000 | 1000 | 400-600 | 8-20 | 7.5-15 | 1450 |

| WLDH-1500 | 1500 | 600-900 | 8-20 | 11-18.5 | 1950 |

| WLDH-2000 | 2000 | 800-1200 | 8-20 | 18.5-30 | 3160 |

| WLDH-3000 | 3000 | 1200-1800 | 8-20 | 18.5-30 | 3300 |

| WLDH-4000 | 4000 | 1600-2400 | 8-20 | 22-37 | 3620 |

| WLDH-6000 | 6000 | 2400-3600 | 8-20 | 37-55 | 5400 |

| WLDH-8000 | 8000 | 3200-4800 | 8-20 | 37-55 | 6880 |

| WLDH-10000 | 10000 | 4000-6000 | 8-20 | 45-75 | 7900 |

What powder materials can be mixed with a Powder Ribbon Mixer?

The Powder Ribbon Mixer can be used to mix general, free-flowing powders, as well as powders with large specific gravities, trace components, sticky materials, and poor flowability.

| Powder Type | Typical Representative | Mixing Characteristics | Applicable Industries |

| Light Fine Powder | Flour, Milk Powder, Pharmaceutical Powder | Easy to fly, requires closed mixing | Food, pharmaceutical |

| Heavy powder | Metal powder, mineral | Need to overcome specific gravity differences | Powder metallurgy, chemical |

| Sticky powder | Putty powder, pregelatinized starch | Requires strong shear dispersion | Building materials, food |

| Heat-sensitive powder | Pharmaceutical raw materials, certain chemicals | Requires gentle mixing, controlled temperature rise | Pharmaceutical, fine chemicals |

| Trace ingredient powders | Active pharmaceutical ingredients and additives | Requires highly uniform distribution | Pharmaceutical and food additives |

Powder Ribbon Mixer Case Studies

| Application Scenarios | Mixing Materials | Mixing Volume (per Batch) | Mixing Time | Equipment Dimensions (Length × Width × Height) |

| Chemical Powder Mixing | Chemical Powder | 600-900L (Working Volume) | 5-15 minutes | 2000×1450×1550 mm |

| Food Additive Production | Star Anise Powder | 600-900L (Working Volume) | 5-15 minutes | 2000×1450×1550 mm |

| Dry Mortar Production | Dry Mortar, Putty Powder, etc. | 1500 kg | 3-6 minutes | 320 × 170 × 140 cm |

| Pharmaceutical industry mixing | Pharmaceutical raw materials, fine chemical powders | 1000-1500 L (feed rate) | 6-15 minutes | 3250 × 1060 × 2000 mm |