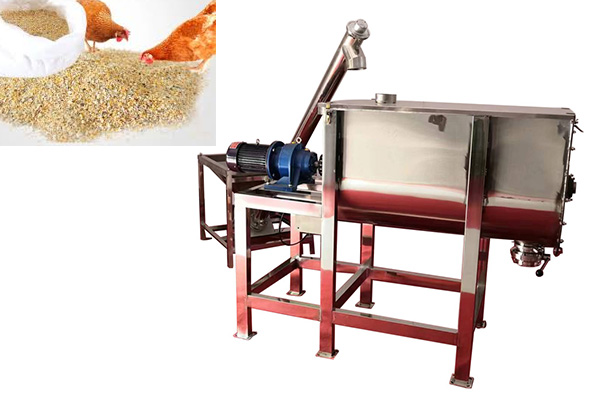

Double Shaft Paddle Mixers powder mixing

The effect of uniform mixing is achieved by reverse rotation of the two-axis blade, and dry powder, micro powder and mixed powder containing a small amount of additives can be processed, at a price of $800-$9,800.

Single batch stirring volume: 50-5000L

Stirring duration: 5-30 minutes

Blade selection: full blade, propeller blade

Material: Carbon steel, stainless steel

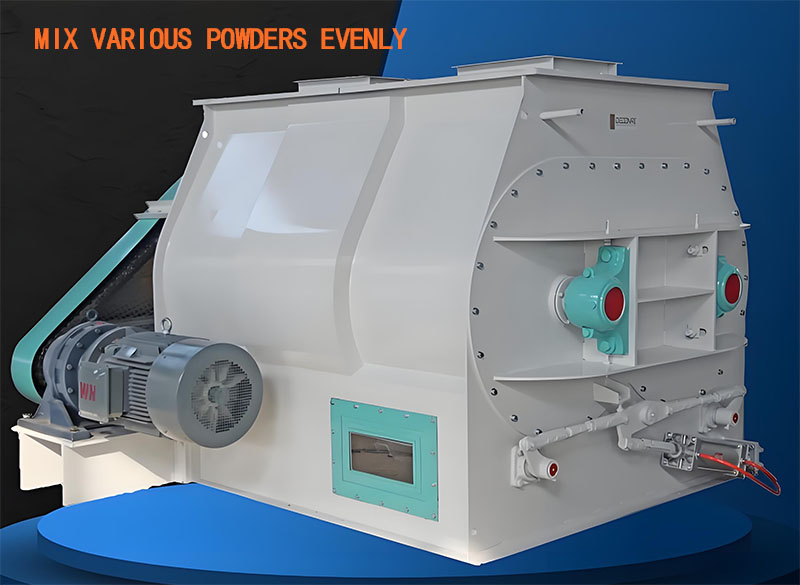

What is Double Shaft Paddle Mixers powder mixing?

Double Shaft Paddle Mixers powder mixing is a mixer for even mixing various powder materials. It drives the powder materials to turn and shear through two reverse-rotating paddles, so that the materials can reach a highly uniform mixing state in a short time. It can be used to stir dry powder, semi-dry powder, and powder mixtures with a small amount of liquid, and even treat materials with large specific gravity differences or uneven particle size distribution, such as cement powder, flour, talc powder, putty powder, feed powder, etc.; the single stirring volume can reach 5000L, and the stirring time is 5-30 minutes, depending on the stirring material.

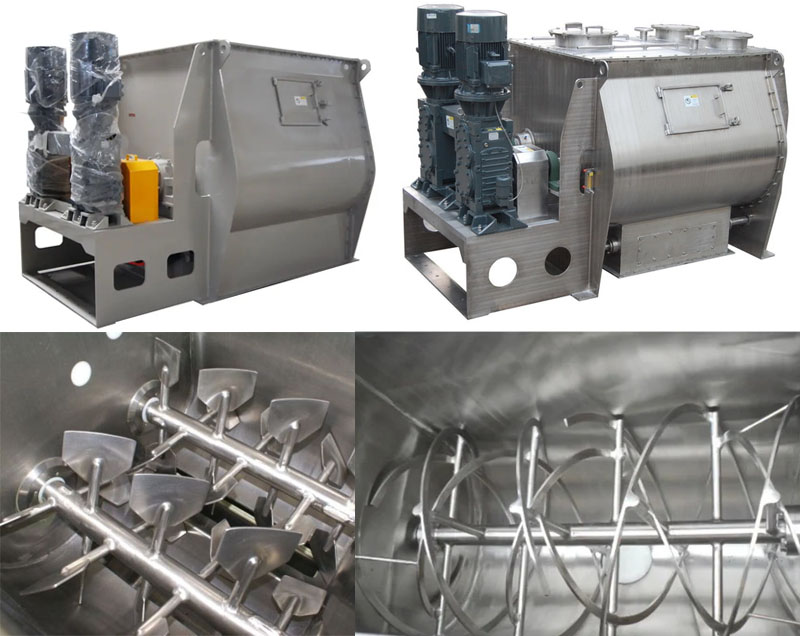

Double Shaft Paddle Mixers powder mixing materials are available in carbon steel and stainless steel. Depending on the mixing material, the equipment's blades are all blades (suitable for coarse powder) and propeller blades (suitable for fine powder), and customized solutions are also provided according to user needs.

What are the types of Double Shaft Paddle Mixers powder mixing?

Double Shaft Paddle Mixers powder mixing can be divided into four types: standard type, anti-caking type, explosion-proof type and food/pharmaceutical type. You can choose the appropriate model based on the powder properties of the stirring. If you are not sure how to choose, you can also contact online customer service to recommend the model for you.

| Model Classification | Adapted powder type | Core Advantages | Typical Application Scenarios |

|

Standard Double Shaft Paddle Mixers powder mixing |

Powders without special requirements (such as feed powder, putty powder) | Mix uniformity≥95%, cost-effective | Feed factory, building materials factory |

|

Anti-caking Double Shaft Paddle Mixers powder mixing |

Easy to absorb moisture and agglomerate powder (such as milk powder, gypsum powder, flour) | With built-in breaking teeth, the efficiency of breaking agglomeration is improved by 30% | Food factories, building materials factories |

|

Explosion-proof Double Shaft Paddle Mixers powder mixing |

Flame-inflammable and explosive powder (such as aluminum powder, dye powder, lithium battery powder) | Motor/electrical explosion-proof design, comply with GB3836 standard | Chemical Park, New Energy Factory |

| Food / Pharmaceutical Double Shaft Paddle Mixers powder mixing | Powders that require hygienic grade (such as milk powder, protein powder, Chinese medicine powder) | 304 Stainless steel cavity + detachable washable blades, no blind spots | Food factories, pharmaceutical factories |

What are the advantages of Double Shaft Paddle Mixers powder mixing?

Double Shaft Paddle Mixers powder mixing uses dual-shaft paddle stirring, which improves the mixing efficiency by 40%. It takes 5-20 minutes for ordinary mixers. The dual-shaft model can achieve uniformity of CV≤5% in just 3-10 minutes. The fiber materials can also be dispersed within 15 minutes. It is also highly adaptable. It can handle all kinds of powders from ultra-fine powder (particle size ≤5μm) to small particles (≤2mm), including materials with large specific gravity differences, which reduces energy consumption by 26% compared to traditional equipment. It adopts a chain transmission system and starts at full load without pressure; the bottom door is designed to open quickly and leave materials without residues, reducing mixing blind spots.

How does Double Shaft Paddle Mixers powder mixing work?

When Double Shaft Paddle Mixers powder mixing is working, the powder will be mixed evenly through three stages:

Throw up and mix: The double-axis blade throws the bottom powder upward to the top of the cavity, allowing the fine powder (such as Chinese medicine powder) to fully contact with the coarse powder (such as medicinal residue powder);

Shear mixing: The shear force at the edge of the blade is directly broken against the agglomerated powder (such as moisture flour) to avoid "the clumped powder is not mixed";

Circulation mixing: The powder forms a "left and left cycle + up and down cycle" in the cavity to ensure that each powder can pass through at least 10 mixing cycles, with the final uniformity stable.

Double Shaft Paddle Mixers powder mixing specifications

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight(kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

What are the applications of Double Shaft Paddle Mixers powder mixing?

Double Shaft Paddle Mixers powder mixing can be used to process various dry powders and ultrafine powders (such as flour, medicinal powder, ceramic powder), and can perfectly mix materials with large differences in specific gravity and particle size (such as additives and main materials), as well as uniformly disperse wet powders with a small amount of liquid (such as flavors and binders). Through strong shear, convection and diffusion, the equipment can quickly solve the problems of agglomeration and segregation that traditional mixers are difficult to deal with, achieving high-precision, uniform mixing without dead corners, and ensuring the final quality of the product.

Below is a display of specific powder materials that can be stirred from different industries. If your powder is not on the list? Contact us to test your powder mixing effect for free.

| Industry | Special powder that can be stirred | Customer Feedback (Excerpt) |

| Metal Industry | Iron powder, aluminum powder, stainless steel powder, copper powder, graphite powder | “Explosion-proof type for stirring aluminum powder, mix evenly in 3 minutes, free of dust” (a hardware factory) |

| Food Industry | Flour, milk powder, protein powder, meal replacement powder, chocolate powder | “Replace powder quickly and meets food grade, and mixes milk powder without odor" (a dairy industry) |

| Chemical Industry | Calcium carbonate powder, talc powder, dye powder, pigment powder, additive powder | “Dye powder mixing has no color difference, and the explosion-proof design is very reliable” (a chemical park) |

| Pharmaceutical Industry | Traditional medicine powder, Western medicine auxiliary material powder, health product powder (such as probiotic powder) | “304 stainless steel + detachable and washable, passed GMP certification” (a pharmaceutical factory) |

| New Energy Industry | Lithium battery positive electrode material powder (ternary material), negative electrode material powder | “The ultra-fine powder has no leakage, and the mixing uniformity reaches 99%” (a battery factory) |

| Building Materials Industry | Cement powder, gypsum powder, putty powder, tile glue powder | “Anti-clamp-type stir-frying gypsum powder without manual disassembling”(a building materials factory) |

Double Shaft Paddle Mixers powder mixing case

| Case Name | A metal powder factory | A food factory | A chemical pigment factory |

| Mixed Materials | Iron Powder + Graphite Powder | Protein Powder + Cereal Powder (Meal Replacement Powder) | Red Dye Powder |

| Customer needs | 1.2 tons of mixed per batch, uniformity≥98%, explosion-proof requirements | 800kg per batch, food-grade hygiene, avoid cross-contamination, and quickly clean | A 2 tons of stir per batch, anti-corrosion and explosion-proof, uniform color without clumping |

| Customized selection scheme | 2000L explosion-proof type | 1000L Food Grade (304 Stainless Steel + Removable Washable Paddle) | 3000L explosion-proof type (316L stainless steel) |

| Effects achieved | Stir for 6 minutes/batch, 20 batches per day, content error of 1%, no leakage | Stir for 4 minutes/batch, it only takes 15 minutes to clean and change materials, and it complies with SC certification | Stir for 7 minutes/batch, the color difference rate of the finished product decreases by 80%, and there is no agglomeration |