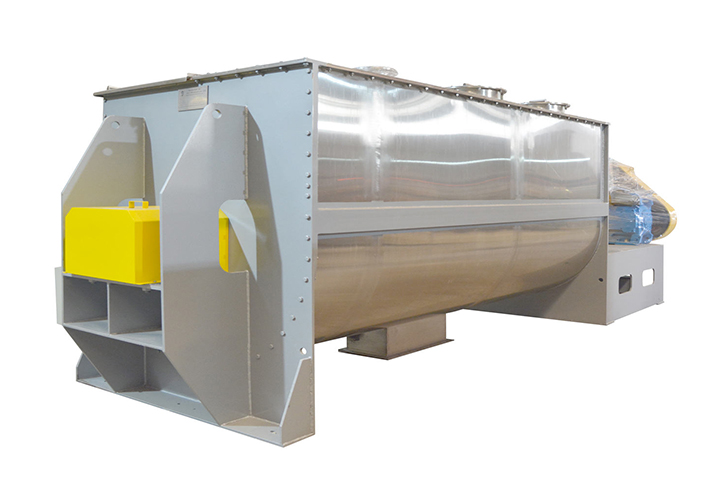

Twin Shaft Paddle Mixer For Feed Mills

The mixing results of a twin shaft paddle mixer for feed mills directly impact the nutritional value and overall performance of feed products. It is a core piece of equipment for feed processing and an indispensable link in industrialized feed production. Mixing Time:30 seconds to two minutes Power:5.5kW-55kW Spindle Speed:29-53 rpm Loading Factor:0.3-0.8

What is a twin shaft paddle mixer for feed mills?

A twin shaft paddle mixer for feed mills is specialized equipment that uses staggered blades on two parallel rotating shafts to achieve uniform mixing of materials. It is suitable for large batches, complex ingredients, and high uniformity requirements in feed production, ensuring uniform nutritional content in each batch and stable composition during subsequent production.

Working principle of the twin shaft paddle mixer for feed mills?

A twin shaft paddle mixer for feed mills uses two counter-rotating paddles to forcefully mix feed ingredients. The equipment's two parallel agitator shafts, rotating at differential or synchronous counter-rotations (typically 200-300 rpm), propel the material. The material is thrown upward, where it interpenetrates and diffuses as it descends, ultimately evenly distributing the feed ingredients and additives. This meets the demands of efficient feed production while ensuring uniform nutritional content.

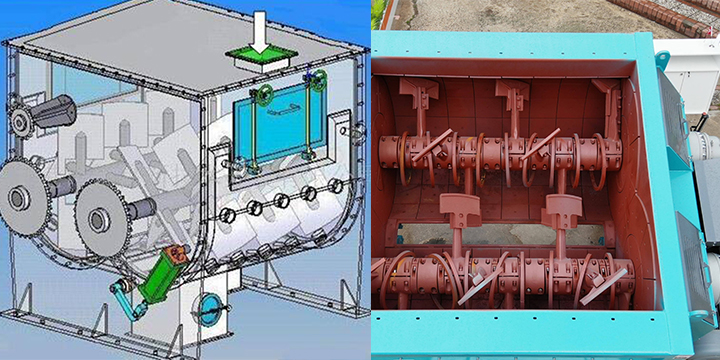

What is the structure of the twin shaft paddle mixer for feed mills?

Container:Constructed of wear-resistant steel plates in a "∞"-shaped, double-grooved welded structure.

Agitator:Twin agitator shafts are fixed to either side of the chamber, with staggered, angled paddles (at an angle of 45°-60°) mounted on them. This is the core component of the mixer.

Power Unit:Consists of dual motors, a reducer, and a coupling.

Inlet and Discharge:The inlet is located at the top of the chamber and can be connected to a screw conveyor or batching scale for quantitative feeding. The discharge is located at the center of the chamber bottom.

Control System:A PLC control cabinet and integrated sensors allow preset parameters such as mixing time, mixing speed, and discharge delay. Automatic start/stop and fault alarms are supported, enabling intelligent control.

What are the advantages of twin shaft paddle mixer for feed mills?

Designed to meet the requirements of "high efficiency, uniformity, and stability" in feed production, twin shaft paddle mixer for feed mills are core equipment for achieving "efficient production, nutritional balance, stability, and reliability" in feed mills. They impact feed quality and animal husbandry performance, making them crucial equipment for large-scale feed production.

High Efficiency:The counter-rotating paddles on the twin shafts create intense convection mixing, resulting in a mixing cycle significantly shorter than single-shaft mixers, meeting the rapid production schedules of feed mills.

High Mixing Uniformity:Mixing uniformity (CV) ≤5%, material residue ≤0.5%.

Wide Application:Efficiently mixes both dry powders and materials containing liquid additives. The machine is wear-resistant and anti-caking, withstanding the long-term wear of hard particles in feed. The shear force of the paddles breaks up raw material agglomerates, ensuring a finely mixed material.

Convenient Operation:Equipped with a PLC touch control system, it supports automatic start/stop and fault alarms, reducing manual intervention.

Application of twin shaft paddle mixer for feed mills?

Due to their efficient mixing, high uniformity, and adaptability to a wide range of materials, twin-shaft paddle mixers for feed mills are widely used in the mixing of various feeds. They adapt to large-scale production, ensure feed quality, and meet diverse farming needs. They are key equipment for achieving nutritional standardization and efficient production in industrial feed production.

They can also be used in the grain and food processing, chemical, building materials and mining, pharmaceutical, and metallurgical industries.

Related news

- What is the purpose of Twin Screw Feeder?

- What is a double-shaft screw conveyor?

- Twin Screw Conveyor Manufacturers

- Types of Twin Screw Conveyor

- 100kg Spice Horizontal Mixer

- Food Grade Spice Mixer

- Crushing and Mixing Machine Fertilizer Production

- Heavy-Duty Ribbon Blender Ceramic Powder And Glaze Mixing