Multihead Packaging Machine

Multihead Packaging Machine weighing range 10-1000 grams, accuracy ±0.5-1.5 grams, compatible bag width 50-200mm, etc. entry-level equipment is about $8,000-$12,000, and mid-to-high-end models can cost up to $15,000-$30,000, depending on the configuration.

Packaging speed: 30-60 bags/minute

Measuring accuracy: ±0.3-1.5 grams

Bag size: 50-200mm wide

Power supply voltage: AC220V/50Hz

Power consumption: about 2.5 kilowatts

What is Multihead Packaging Machine?

Multihead Packaging Machine is a high-precision, high-speed automated weighing and packaging equipment. Its principle is that multiple weighing heads (usually 10, 14 or 20 heads) operate simultaneously to quickly combine materials close to the target weight, and then the equipment below automatically packages and seals them. Its advantages include high speed, high precision, low loss, and can greatly improve production line efficiency. Typical output can reach 30-80 bags/minute, depending on material characteristics and bag structure. The main technical parameters include weighing range 10-1000 grams, accuracy ±0.5-1.5 grams, compatible bag width 50-200mm, etc. In terms of price, entry-level equipment is about $8,000-$12,000, and mid-to-high-end models can cost up to $15,000-$30,000, depending on the configuration.

What are the types of Multihead Packaging Machines?

Multihead Packaging Machine can be divided into many types according to the material conveying method, among which Z-belt, Z-lift and spiral conveyor are three typical structures.

Z-type belt conveyor: The material is transported from low to high through a Z-shaped belt, and high-speed and accurate measurement is achieved through multiple sets of weighing heads. It is suitable for vertical lifting of light, bulk materials, such as potato chips, freeze-dried foods, etc. Its advantage is that the conveying is stable and can reduce material damage.

Z-type lifting model: It adopts a chain plate or tray structure, and realizes material lifting through a Z-shaped track. It is suitable for continuous conveying of granular or block materials, and has the characteristics of strong carrying capacity and high efficiency.

Screw conveyor type: The spiral blades are used to rotate and push the material forward. It is suitable for the conveying of powdered or small granular materials (. The material flow rate can be accurately controlled by adjusting the spiral speed, and the area occupied is small.

What are the advantages of Multihead Packaging Machine?

Multihead Packaging Machine mainly has the advantages of fast and accurate, labor-saving, traceable, and easy maintenance, as follows:

High precision and high efficiency: The multi-head weighing system quickly matches the target weight through parallel calculation, avoiding the repeated trial and error of traditional single-head scales, and improving efficiency by 3-5 times. For example, the packaging speed of coffee beans can reach 80 bags/minute, and the error rate is less than 0.5%.

Reduced labor costs: The automated process reduces manual intervention, and only 1-2 operators are required per shift, saving 50% of manpower compared to traditional packaging lines.

Data traceability: The built-in production record system can export data such as weight and speed of each batch, which meets the HACCP standards of the food industry.

Easy maintenance design: The modular structure supports the rapid replacement of weighing units or hoppers, and the maintenance time is shortened to 1/3 of traditional equipment.

Common parameters of Multihead Packaging Machine

| Type | TH420 | TH520 | TH720 |

| Bag length | 80-300mm | 80-400mm | 100-400mm |

| Bag width | 50-200mm | 80-250mm | 180-350mm |

| Max width of roll film | 420mm | 520mm | 720mm |

| Packing speed | 5-30bags/min | 5-50bags/min | 5-50bags/min |

| Air consumption | 0.65mpa | 0.65mpa | 0.65mpa |

| Gas consumption | 0.3m³/min | 0.4m³/min | 0.4m³/min |

| Power voltage | 220V | 220VAC/50HZ | 220VAC/50HZ |

| Dimension | (L)1320*(W)950*(H)1360 | (L)1150×(W)1795×(H)1650mm | (L)1780×(W)1350×(H)1950mm |

What is the Multihead Packaging Working principle of the machine?

The core of the Multihead Packaging Machine is to improve packaging efficiency through the synchronous operation of multiple weighing units. The advantage lies in parallel processing, and the speed of a single machine can reach 100-200 bags/minute, which is far superior to single-head equipment. Its workflow is divided into three steps:

Feeding stage: The material is conveyed to the weighing bucket through a vibrating feeder, belt or screw, and the system distributes the material according to the preset weight.

Weighing and metering: Each weighing head independently detects the weight of the material, and the microprocessor quickly adjusts the filling amount through the sensor feedback data to ensure accuracy (usually the error is ±0.1%-1%).

Filling and sealing: After metering, the material falls into the packaging bag or container, and then heat-sealed or sewn to complete the automated packaging.

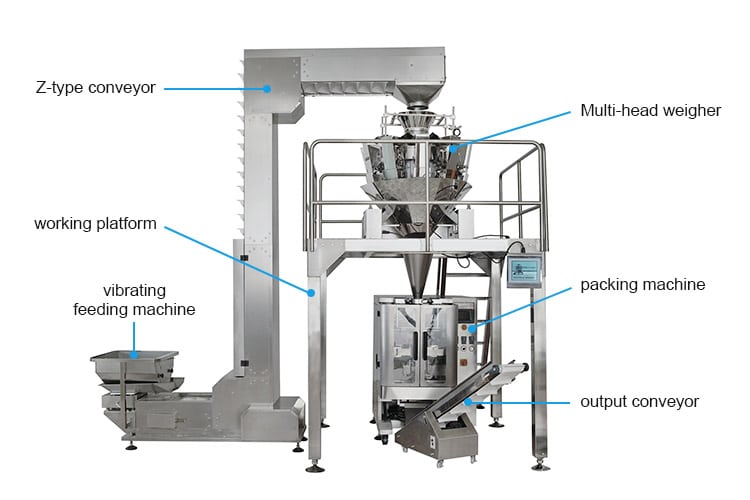

Multihead Packaging Machine Structure

The Multihead Packaging Machine consists of six main structures: the Z-type conveyor is used to convey the material, the vibrating feeder realizes uniform feeding, the multi-head scale performs accurate weighing, the packaging machine completes the packaging, the output conveyor outputs the finished product, and the working platform is convenient for operation and maintenance.

Application scenarios of Multihead Packaging Machine

Multihead Packaging Machine's highly flexible structure and combination logic make it an indispensable packaging tool on modern production lines. It achieves fast and accurate packaging through multi-column synchronous operation in multiple fields. Its core functions and application scenarios are as follows:

Food industry: used for small bag packaging of granular or powdered materials such as coffee, solid beverages, condiments, and candies. Through the synchronous unloading of multi-column metering devices and the four-side sealing technology, multiple bags can be packaged at one time, greatly improving production capacity.

Pharmaceutical industry: For small-dose drugs such as pills and capsules, a high-precision servo motor is used to drive the metering cup to ensure that the filling error of each bag is less than ±0.5%, and supports customization of special-shaped bags (such as self-supporting bags) to meet special needs such as moisture-proof and light-proof for drugs.

Daily chemical industry: Suitable for fluid or paste materials such as facial masks and shampoos, and composite films such as PET/AL/PE are processed through roller heat sealing technology to achieve sealed packaging. Modular design supports 4-12 channel expansion and flexibly responds to product switching of different specifications.

Agricultural products industry: Used for moisture-proof and sealed packaging of small particle materials such as seeds and fertilizers. The horizontal unloading structure reduces material residue, and the vibration device enhances the filling stability of materials with poor fluidity to ensure the consistency of weight of each bag.

Price of Multihead Packaging Machine

The price of a Multihead Packaging Machine is affected by many factors, including the equipment configuration, the number of weighing heads, the degree of automation and intelligent integration, production speed and accuracy requirements, applicable material characteristics, and brand awareness.

Economical 10-head equipment: The price is about $8,000-$12,000. This model is designed for small factories and is equipped with 10 weighing heads. It uses basic high-precision sensors to ensure that the weighing error is controlled within ±1g. It is equipped with a simple touch screen operation interface, supports recipe storage and fast switching, and is suitable for common materials such as granules and powders. The body adopts a carbon steel structure and comes standard with a stainless steel weighing pan. The working speed is 30-50 bags/minute, which is suitable for daily production. For scenes below 5 tons. Basic vibrating feeder is optional, but manual feeding and packaging are required.

Standard 14-head equipment: The price range is $13,000-$18,000. The equipment is equipped with industrial-grade sensors with an accuracy of ±0.5g, a 7-inch color touch screen, an integrated PLC control system, and supports multi-stage variable speed feeding (coarse/fine feeding). The body adopts a 304 stainless steel frame, which is more corrosion-resistant and can reach a speed of 60 bags/minute, which is suitable for medium production capacity requirements (daily output 8-12 tons). Optional spiral feeder or belt conveyor , compatible with materials with high viscosity.

High-end 20-head equipment: Price range is $20,000-$30,000. Designed for high-production lines, the 20 weighing heads adopt a modular layout and are equipped with ±0.2g ultra-high precision sensors and anti-interference circuits. Core upgrades include IP65 waterproof chassis, quick-release weighing bucket (3 seconds release and cleaning), and dual-channel vibrating feeding system with a speed of up to 80 bags/minute. New fault self-diagnosis function, real-time alarm through the HMI interface. The body is made of all stainless steel, with optional pneumatic sealing device, suitable for wet or High hygienic environment.

Whole-line linkage system: The price range is $35,000-$50,000, integrating automatic feeder (vacuum suction or spiral conveyor), 20-head weighing host, servo-driven vertical packaging machine, online metal detector and laser coder, and realizing unmanned production through central PLC synchronous control. Supports docking with MES system to monitor production, failure rate and other data in real time. The whole line speed can reach 120 packs/minute, and the daily processing capacity exceeds 20 tons, which is suitable for continuous operation of large food and pharmaceutical companies.

Multihead Packaging Machine Supplier

Our factory adopts a customized multi-head combination structure in the manufacture of Multihead Packaging Machine, which is flexibly adapted to different materials such as particles, powders, and liquids, supports multi-scale linkage or independent work, and significantly improves the efficiency of complex packaging scenarios. Providing full-chain support from solution design to after-sales maintenance, it has accumulated a large number of successful cases in the fields of food, medicine, and chemical industry, and helps customers reduce costs and increase benefits with highly adaptable equipment.