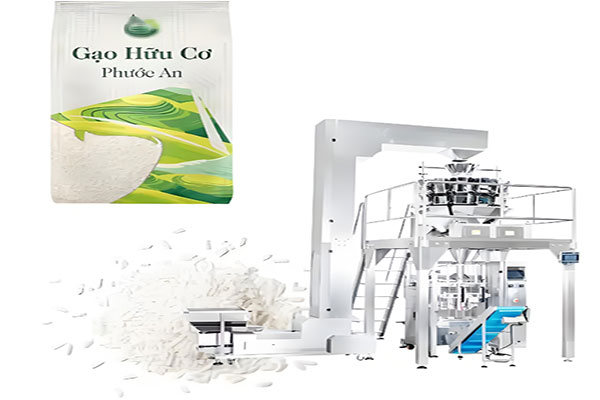

Fully Automatic Multihead Packaging Machine

Fully Automatic Multihead Packaging Machine suitable for packaging granular, flaky, or fragile materials such as puffed foods, candies, nuts, frozen foods, and pet food. Output generally reaches 30-60 bags per minute, depending on the number of heads and material type. Equipment prices range from approximately M$9,000 to $30,000. Packaging Speed: 30-60 bags/minute Bag Dimensions: 80-320mm in Width, 100-400mm in Length Power Supply: 220V/380V, 3-6kW Weighing Method: Electronic Scale/Screw/Combination Weigher Packaging Accuracy: ≤±0.1-1% Packaging Materials: Composite Film, Aluminum Foil Bags Sealing Method: Heat Seal/Cold Seal Machine Weight: 350-1200kg

What is a Fully Automatic Multihead Packaging Machine?

Fully Automatic Multihead Packaging Machine is used to accurately weigh and automatically package granular, flaky, or irregularly shaped materials. The machine is typically equipped with multiple weighing units (usually 10, 14, 20, or more). Using a combination algorithm, it quickly calculates the material combination closest to the target weight, achieving high-speed and accurate weighing. The machine primarily consists of a loading system, a combination weigher, a bag-making and sealing machine, a control system, and a finished product delivery system. Its functions cover the entire process of automatic weighing, bagging, filling, sealing, bag cutting, and printing. It is suitable for packaging granular, flaky, or fragile materials such as puffed foods, candies, nuts, frozen foods, and pet food. Output generally reaches 30-60 bags per minute, depending on the number of heads and material type. Equipment prices range from approximately $9,000 to $30,000, depending on the configuration.

Features of the Fully Automatic Multihead Packaging Machine

Fully Automatic Multihead Packaging Machine features high weighing accuracy, high production capacity, a wide range of compatible materials, and a rational structure:

Fully Automatic Operation: Integrates automatic loading, weighing, unloading, bagging, filling, sealing, and coding, enabling unmanned operation, reducing manual intervention and improving production efficiency. High Automation: Supports automatic alarms, low-material detection, and abnormal sealing notifications.

Multi-Head Combination Weighing System: Equipped with 10 or 14 high-precision weighing devices, it automatically combines the weighing units based on material weight, ensuring consistent weight for each bag, with an error within ±0.1g.

High Production Capacity: Operating speeds can reach 30 to 80 bags per minute, making it suitable for large-scale continuous production and widely used in industries such as food, nuts, frozen foods, and snacks.

Intelligent Control System: Utilizing PLC control and a touchscreen human-machine interface, it offers simple operation, flexible parameter settings, and supports quick switching between multiple packaging formats.

Strong Adaptability: Compatible with various packaging formats, including pillow bags, stand-up bags, and gusseted bags, it meets diverse material and packaging needs.

Rational Structural Design: The entire machine is constructed of stainless steel, meeting food safety standards, allowing for easy cleaning and maintenance, stable operation, and a low failure rate.

Fully Automatic Multihead Packaging Machine Parameters

| Model | LD-420 | LD-520 | LD-720 | LD-900 | LD-1050 | LD-1200 |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 100-800mm | 100-1000mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-505mm | 290-580mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | 400mm | 400mm | 400mm |

| Pakaging Rate | 5-60bag/min | 5-60bag/min | 5-55bag/min | 5-20bag/min | 5-20bag/min | 5-20bag/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.720mm | Max.900mm | Max.900mm | Max.1200mm |

| Measurement Range | 150-1500ml | 5-2000ml | 4000ml | 1-25L | 1-25L | 1.5L-45L |

Fully Automatic Multihead Packaging Machine Price

Fully Automatic Multihead Packaging Machines meet different functional requirements depending on the components they are equipped with. Some machines can weigh and seal granular materials, while others are suitable for weighing complex mixed materials. Common functional configurations and prices are as follows:

Basic models generally feature a 10- or 14-head combination weigher. They are suitable for automatically weighing, bagging, and sealing granular materials such as candy, melon seeds, and rice. Prices range from approximately US$8,000 to US$12,000, making them suitable for small and medium-sized businesses seeking initial automation.

Mid-range packaging machines incorporate a vibrating loader, a Z-shaped conveyor, and a finished product delivery conveyor, enabling complete operation from loading to finished product delivery. These machines are suitable for medium-volume production and are priced between approximately $15,000 and $20,000. This type of equipment effectively reduces manual intervention and improves production efficiency, making it ideal for businesses with high capacity and automation requirements.

High-end intelligent models feature high-speed 14- or 16-head combination weighers with multi-material mixed weighing, touchscreen PLC control, and memory weighing. They are suitable for products with complex packaging requirements, such as mixed nuts and frozen foods. These machines typically cost between $25,000 and $35,000 and are ideal for factories requiring high packaging precision and variety.

Fully automated packaging lines can also be equipped with metal detectors, weight feedback systems, and automatic rejection mechanisms. These provide full-process automated monitoring, quality control, and rejection of abnormal products. They are suitable for large-scale, continuous production with stringent product quality control requirements, and typically cost between $40,000 and $55,000.

Fully Automatic Multihead Packaging Machine Optional Devices

To accommodate diverse production needs, the Fully Automatic Multihead Packaging Machine can be equipped with the following optional devices. These auxiliary equipment greatly enhances the flexibility and scalability of the packaging system:

Z-type conveyor: Responsible for vertical material conveyance, with a conveying capacity of 3-6 cubic meters per hour. It is suitable for conveying fragmented, granular, or fluid materials.

Output conveyor: Transports sealed finished products to the next process. The conveyor speed can be adjusted according to the production cycle, facilitating subsequent packaging or boxing.

Vibrating hopper: Vibrates to ensure uniform material flow, preventing blockages and uneven material discharge, thereby ensuring continuous and stable operation.

Printer module: Prints information such as the production date, batch number, and QR code on the packaging bags in real time for easy product traceability.

Metal detector: Detects foreign metal contaminants in finished or semi-finished products, enhancing product safety and quality assurance and preventing quality incidents caused by foreign matter.

Punching and die-cutting devices: These devices support various packaging designs, including hanging holes, easy-tear notches, and handles, meeting customer demands for diverse packaging functionality and convenience.

How does the Fully Automatic Multihead Packaging Machine work?

Fully Automatic Multihead Packaging Machine operates as follows: loading → weighing → bagging → filling → sealing → cutting → output. Materials are fed into the hopper of a multihead combination weigher via an elevator. Each weighing head in the multihead weigher weighs the materials simultaneously and automatically combines the materials to the target weight. The materials then fall into the former, where the packaging film is fed by a film roll and formed into bags. Next, the materials are automatically filled into the bags, and the sealing device heat-seals the bag openings before the finished bags are cut. The packaged products are then transported via an output conveyor, ready for boxing or further processing.

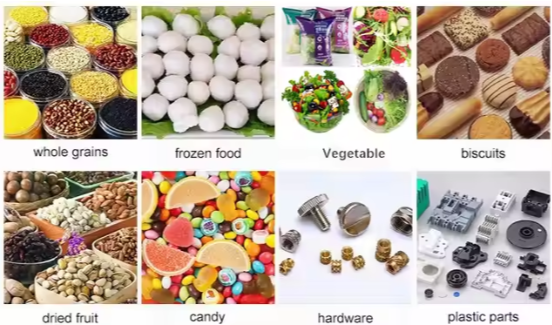

Fully Automatic Multihead Packaging Machine Applications

The Fully Automatic Multihead Packaging Machine excels in the following scenarios: In the food industry, it is suitable for quantitative packaging of puffed foods, candies, nuts, dried fruits, biscuits, and frozen foods. In the condiment industry, it can be used to package powdered or granular condiments such as chicken essence, dry seasonings, and soup sachets. In the daily chemical industry, it is commonly used to package non-food items such as laundry detergent, bath salts, and granular detergents. In the hardware industry, it can precisely package small hardware accessories such as screws, nuts, and washers. In the pharmaceutical industry, it is suitable for weighing and packaging products such as tablets, capsules, and Chinese herbal medicine slices. By performing various functions, the machine meets the quantitative packaging needs of various granular, flaky, and irregularly shaped materials.