Which is better, a cone crusher or a jaw crusher?

Saturday October-18 2025 16:33:10

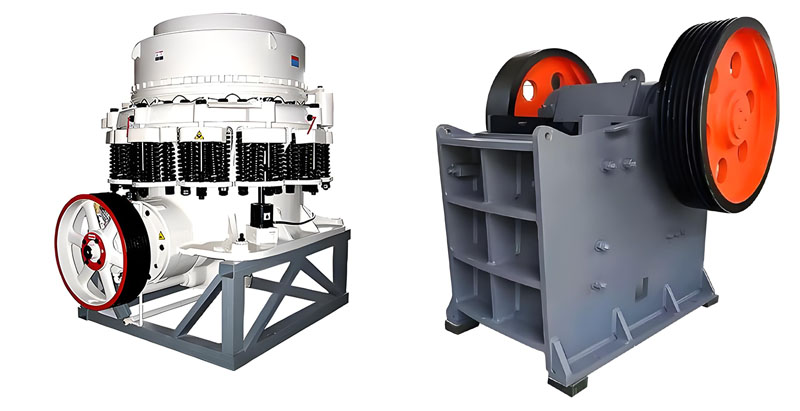

Which is better, a cone crusher or a jaw crusher? Different crushing materials and output requirements require different equipment. Jaw crushers are suitable for coarse crushing, while cone crushers are suitable for medium and fine crushing. However, in terms of crushed material particle shape, cone crushers are superior. Of course, the equipment used also varies depending on the crushing requirements, such as material properties, feed size, discharge size, and crushing capacity. The following will explain in detail the differences between cone crushers and jaw crushers, including their principles, feed/discharge size, characteristics, structure and material, and application materials.

What is the difference between a cone crusher and a jaw crusher?

To understand which is better, a cone crusher or a jaw crusher, we first need to understand their operating principles, advantages and disadvantages, feed and discharge sizes, and differences in application scenarios.

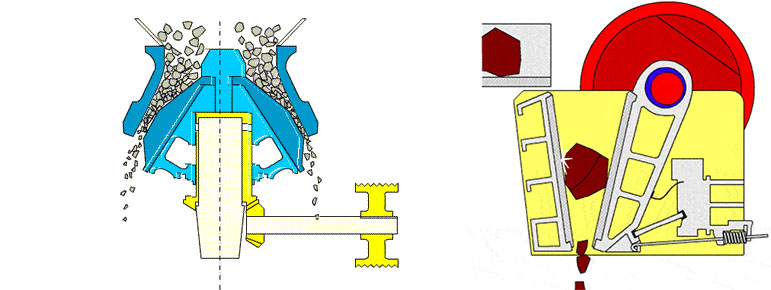

Working Principle Comparison

Cone crushers and jaw crushers differ in their operating principles. Cone crushers use a continuous lamination crushing principle, where materials are crushed by the continuous squeezing and bending action between the moving and fixed cones. Jaw crushers, on the other hand, use an intermittent squeezing crushing principle, where the moving jaw periodically oscillates around a fixed axis, creating a squeezing and shearing action with the fixed jaws to break up bulky materials.

Comparison of Feed and Discharge Particle Sizes

Cone crushers and jaw crushers have different feed and discharge particle sizes. Jaw crushers have a larger feed opening, typically between 100-1500mm, and can handle large materials with a diameter of over 1 meter, making them suitable for coarse crushing. Cone crushers, on the other hand, have a smaller feed opening, typically between 50-300mm. They are typically used for secondary crushing after coarse crushing and are suitable for medium and fine crushing. Jaw crushers have a coarser discharge size, typically between 10-300mm, and the particle size is often irregular and uneven. Cone crushers produce finer particles, ranging from 5-80mm, and the particle shape can be precisely controlled by adjusting the discharge opening, achieving a more uniform particle size.

Application Comparison

The different feed and discharge sizes of cone crushers and jaw crushers also mean that their application scenarios differ. Cone crushers are commonly used for medium to fine crushing of low- to medium-hardness materials, such as limestone, river pebbles, and ore for secondary crushing, and are often used in aggregate processing and concrete production. Jaw crushers, on the other hand, are suitable for coarse crushing of hard, large-block materials, such as granite, basalt, and ore, and are often used in the initial crushing stage of a production line.

Which is better, a cone crusher or a jaw crusher? Comparison chart

| Comparison Dimensions | Jaw Crusher | Cone Crusher |

| Crushing Principle | Uses extrusion crushing, with the movable and fixed jaws simulating a "chewing" action to crush the material | Uses laminated crushing, crushing materials through continuous extrusion and impact between the moving and fixed cones.; |

| Applicable Materials | Various medium-to-high hardness stones, especially suitable for wet and sticky materials | Medium-to-high hardness, highly abrasive stones (such as granite and basalt) |

| Finished Particle Shape | The product is flaky and has a poor cubic feel | The product is cubic, with good particle shape and low needle-like content |

| Inlet/Outlet Particle Size | Large feed particle size (up to 1500mm), suitable for coarse crushing. | The feed size is relatively small (usually ≤480mm), and the discharge size is adjustable over a wide range (3-64mm). |

| Structure and Materials | The structure is simple, with the main components being the frame, jaw plate, and eccentric shaft; the jaw plate is made of wear-resistant materials such as high-manganese steel. | The structure is complex, consisting of the frame, movable cone, fixed cone, and hydraulic system; the liner is made of ultra-high-alloy manganese steel. |

When choosing between a cone crusher and a jaw crusher, a jaw crusher is recommended for coarse crushing of large, blocky materials, or if budget constraints and low particle size requirements are present. A cone crusher is recommended for medium to fine crushing of materials with specific output particle size requirements. Furthermore, in production lines, a cone crusher and jaw crusher are often used together for better crushing results.

Minerals Coarse Crusher

Minerals Coarse Crusher