Convenient processing of low-grade copper oxide ores

Focus on providing convenient and efficient low-grade copper oxide ore processing solutions to improve resource utilization and reduce production costs.

Price: $500-$30,000

Applicable ore grade: 0.5% - 2% Cu

Processing capacity: 100 - 1000 tons/day

Recovery rate: up to 85%

What is convenient processing of low-grade copper oxide ores?

Convenient Processing of Low-Grade Copper Oxide Ores offers a cost-effective and environmentally sustainable solution for extracting copper from low-grade deposits (typically 0.2%-1.5% Cu). Our integrated flotation-leaching-bioleaching technology ensures high recovery rates (50%-98.5%), reduced acid consumption, and minimal environmental impact.

What are the advantages of convenient processing of low-grade copper oxide ores?

Higher recovery: Up to 80.98% copper recovery through optimized flotation leaching process1

Lower operating costs: Lower acid and energy consumption compared to traditional methods

Environmentally friendly: Closed-loop water recycling to minimize carbon footprint

Flexible process: Applicable to heap leaching, agitated leaching and bioleaching

What types of convenient processing of low-grade copper oxide ores are there?

We provide four main convenient processing of low-grade copper oxide ores, including acid leaching, ammonia leaching, flotation, and bioleaching.

Acid leaching: Applicable to copper oxide ores with high mud content. Copper elements are leached out through dilute sulfuric acid. The process is simple and the cost is low.

Ammonia leaching: Applicable to ores containing alkaline gangue. Ammonia solution is used to selectively leach copper, reduce impurity interference, and improve purity.

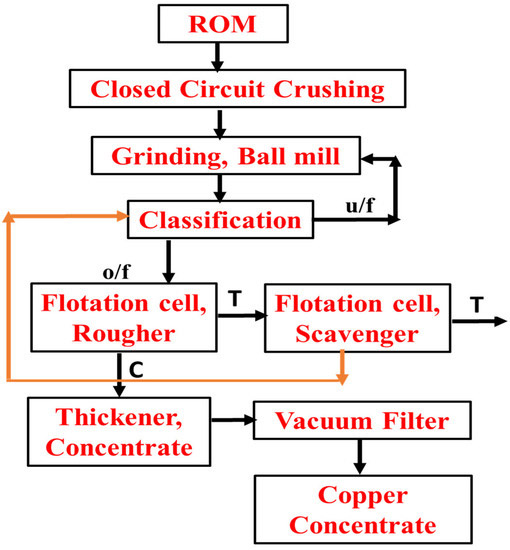

Flotation: Including sulfide-xanthate flotation, fatty acid flotation, etc., suitable for different types of copper oxide ores to improve recovery rate.

Bioleaching: Use microorganisms to promote the dissolution of copper, environmentally friendly and energy-saving, suitable for processing difficult-to-select ores.

How is low-grade copper oxide ores processed in a convenient processing?

Convenient processing of low-grade copper oxide ores is to select appropriate leaching agents or flotation agents to destroy the combination of copper and other elements in the ore and promote the dissolution or flotation separation of copper. For example, the acid leaching method uses dilute sulfuric acid to react with copper oxide to generate soluble copper salts; the ammonia leaching method increases the solubility of copper by forming a copper-ammonia complex; the flotation method adjusts the chemical environment of the slurry to combine copper minerals with foam to achieve separation.

What are the applications of convenient processing of low-grade copper oxide ores?

Convenient processing of low-grade copper oxide ores is widely used in copper mining and smelting enterprises, especially for processing low-grade and difficult-to-select copper oxide ores. It also has significant advantages in comprehensive resource utilization and tailings treatment.

Mining companies: Maximize profits from low-grade (less than 1% copper) deposits

Heap leaching operators: Improve copper recovery and reduce acid costs

Environmentally friendly mining companies: Lower carbon footprint compared to smelting

Projects in Africa and South America: Adapt to tropical and arid climates

Convenient processing of low-grade copper oxide ores Customer Cases

A mining company: Using this product to process 1.2% grade copper oxide ore, the copper recovery rate increased to 80%, and the annual revenue increased by 5 million yuan.

A smelter: Introducing ammonia leaching to treat ore containing alkaline gangue, the impurity content was reduced by 30%, and the product quality was significantly improved.

An environmental protection project: Using bioleaching to treat tailings, successfully recovering remaining copper resources and reducing environmental pollution.