Gravityless Twin Shaft Paddle Mixer

It can mix powders, granules, and viscous materials in a zero-gravity environment, ensuring uniform and consistent mixing. Price ranges from $400.00 to $5,500.

Mixing capacity: 200-3000 kg/batch

Paddle speed: 18-30 r/min

Motor power: 5.5-55 kW

Material: Carbon steel, 304/316L stainless steel

What is a Gravityless Twin Shaft Paddle Mixer?

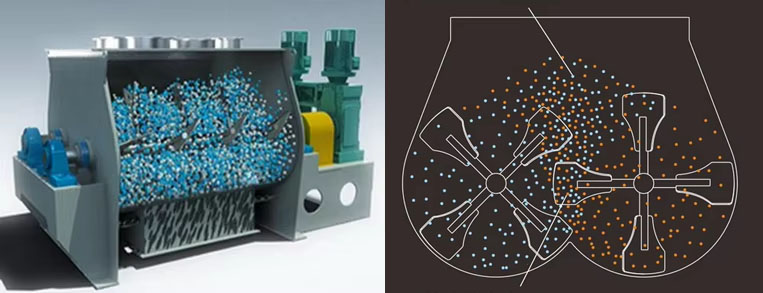

A Gravityless Twin Shaft Paddle Mixer is used for mixing powders, granules, granules, or powders, even with a small amount of liquid. Its dual counter-rotating paddles create a momentary state of weightlessness. These paddles propel the materials, creating a staggered, shearing, and convection effect, quickly breaking up material agglomerates and achieving highly uniform mixing (typically ≥95%) with zero dead zones. It can mix materials such as dry mortar, paint powders, feed additives, and chemical raw materials. The mixing capacity typically ranges from 1 to 50 m³/batch, and can be customized to meet production needs. The paddles are available in standard paddle styles (suitable for general powders and faster mixing) and propeller styles (for sticky/agglomerated materials, enhancing dispersion).

What types of Gravityless Twin Shaft Paddle Mixers are available?

Gravityless Twin Shaft Paddle Mixer can be divided into four types according to the properties of the materials being mixed: standard type, wear-resistant type, corrosion-resistant type and high-temperature resistant type. You can choose according to the materials you need to mix.

| Model Type | Core Compatible Materials | Applicable Scenarios | Hourly Processing Capacity |

| Standard General Purpose | Ordinary Dry Powder (e.g., Cement, Flour), Granular Materials (e.g., Plastic Granules) | Building Materials, Primary Food Processing, Feed Production | 0.5-20 Tons |

| Wear-Resistant Type | High-hardness materials (e.g., ore powder, metal chips, corundum) | Metallurgy, abrasive processing, ore pretreatment | 1-30 tons |

| Corrosion-Resistant Type | Acidic/Alkaline materials (e.g., pigments, chemical additives, battery materials) | Chemical, electroplating raw materials, new energy material production | 0.8-25 tons |

| High-Temperature Tolerant Type | High-temperature materials (e.g., hot-melt resin, calcined lime, high-temperature ore powder) | High-temperature building materials, post-chemical reaction mixing | 1-35 Ton |

What are the advantages of the Gravityless Twin Shaft Paddle Mixer?

The Gravityless Twin Shaft Paddle Mixer uses gravity-free mixing, allowing materials to "suspend and collide," reducing mixing time by 40% compared to traditional equipment. For example, 10 tons of dry mortar can be mixed in 30 minutes, with uniformity far exceeding industry standards (≤0.5% deviation). It can even mix materials with large differences in specific gravity, mix ratio, and particle size, effectively mixing materials with mix ratios ranging from 1:1000 to 10,000, or even higher, without segregation. The paddles feature a bionic design, with a clearance of ≤1mm from the drum wall, eliminating any residual material. The wear-resistant/corrosion-resistant model's core components have a lifespan 2-3 times longer than conventional mixers. Its simple structure means routine maintenance requires only cleaning the paddles and checking the bearings, eliminating the need for specialized personnel.

How does the Gravityless Twin Shaft Paddle Mixer work?

When the Gravityless Twin Shaft Paddle Mixer is in operation, its two shafts rotate at high speeds in opposite directions. The paddles use the rotational force to propel the material in the chamber in a complex lateral and longitudinal motion. On the one hand, the paddles toss the material upward from the bottom of the chamber. When the material reaches a certain height, its gravity and the paddle's lifting force briefly balance, resulting in a "gravityless suspension state," completely breaking up material agglomerates. On the other hand, the counter-rotating shafts drive the material through interlaced convection and mutual shear between the two shafts, further breaking down density and particle size differences and preventing stratification. Finally, after a short period (typically 30-120 seconds) of cyclical ejection, shearing, and convection, the material achieves a highly uniform mix (generally ≥95%). Once mixed, the material is quickly discharged through the bottom discharge valve.

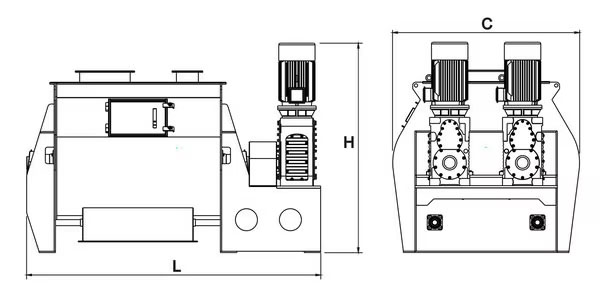

Gravityless Twin Shaft Paddle Mixer Specifications

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight(kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

What are the applications of the Gravityless Twin Shaft Paddle Mixer?

The Gravityless Twin Shaft Paddle Mixer can handle a variety of materials, including powder-to-powder mixing, powder-to-granular mixing, granular-to-granular mixing, solid-liquid mixing with the addition of a small amount of liquid, and mixing materials with large specific gravities and fibrous materials.

Building Materials Industry: Suitable for mixing dry mortar, cement putty, tile adhesive, insulation mortar, gypsum powder, and other materials. Standard general-purpose (normal dry powder) and wear-resistant reinforced (mortar containing quartz sand) models are recommended.

Chemical Industry: Suitable for mixing pigments, dyes, chemical additives, battery positive and negative electrode materials, rubber particles, and other materials. Corrosion-resistant (acidic and alkaline) Gravityless Twin Shaft Paddle Mixers are recommended.

Food/Pharmaceutical Industry: Suitable for mixing flour, food additives, traditional Chinese medicine powder, health supplement ingredients, and milk powder. 304 stainless steel anti-corrosion models (meeting food/pharmaceutical grade standards) are generally preferred to prevent cross-contamination. Metallurgy/Abrasive Industry: Suitable for mixing materials: metal powders (iron powder, aluminum powder), ore powder, corundum, and abrasive particles. The wear-resistant and reinforced Gravityless Twin Shaft Paddle Mixer is recommended.

Reference: A metallurgical plant used a 15-ton/hour wear-resistant model to mix iron powder and alloy particles. The paddles showed no noticeable wear after one year of use, and the mixing efficiency was 50% higher than the old equipment.

Other Industries: Suitable for mixing feed additives, organic fertilizer granules, plastic masterbatch, and paint pastes. The machine model can be matched to the material characteristics (e.g., for paint pastes, a general-purpose model with scraping blades is recommended).

Optional Configurations for the Gravityless Twin Shaft Paddle Mixer

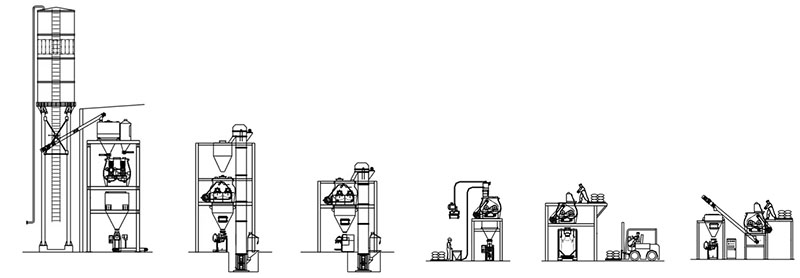

Placed within the production line and integrated with the raw material silo, dosing system, conveying system, production silo, and packer, the Gravityless Twin Shaft Paddle Mixer enables large-scale production. All equipment in the production line should be strategically positioned and coordinated to achieve maximum efficiency.

Configuration 1: Vacuum feeder, storage silo under the mixer, and packer under the silo.

Configuration 2: Manual feed with a manual lift, bulk bag packer under the mixer.

Configuration 3: Manual feed, discharge to silo, and packaging.

Gravityless Twin Shaft Paddle Mixer Cases

| Customer Industry | Application Scenarios | Equipment Model | Mixed Materials | Mixing Results / Customer Feedback |

| Chemical Industry | Pigment and Additive Mixing Production | WZ-2000 | Organic Pigments, Calcium Carbonate Fillers, Dispersing Agents | Mixing Uniformity > 98%, 2-3 Minutes / Batch mixing eliminates stratification issues caused by differences in specific gravity, increasing production capacity by 30%. |

| Building Materials Industry | Specialty Dry-Mix Mortar Production | Integrated Zero-Gravity Mixer | Cement, Quartz Sand, Rubber Powder, Anti-Crack Fiber | Combined with a fully automated control system, this machine achieves an annual production capacity of 400,000 tons, with a mixing error of ±0.5%. The equipment's wear-resistant lining extends its service life by 30%. |

| Feed Industry | Organic Poultry Feed Processing | Dinnissen Twin-Shaft Mixer | Grain Flour, Vitamin Premix, Vegetable Oils and Fats | Mixing a 4-ton batch in just 4 minutes, with >95% particle integrity retention, a 20% increase in production capacity, and 100% equipment reliability for continuous operation. |

| Food Additive Industry | Baking Ameliorator Mixing | WZ-1000 | Flour, Emulsifiers, Enzymes, Nutritional Enhancers | The stainless steel chamber meets food hygiene standards, achieving 97% mixing uniformity and <0.1% residue, increasing single-shift production to 15 tons. |