Cone Crusher Price

Wednesday October-15 2025 17:09:43

Cone Crusher price is usually between $800 and $210,000. Its price is not fixed and mainly depends on the model of the equipment, crushing capacity, configuration and customization. For example, the price of a small single-cylinder hydraulic press with a processing capacity of 30 tons is significantly lower than that of a large single-cylinder hydraulic press with a processing capacity of 300 tons. This is because large equipment requires a more solid raw material structure, a more powerful drive motor, and higher labor costs to meet large-scale mining operations.

Cone crusher prices range widely. Conventional single-cylinder small-sized machines (30-100 tons/hour) cost approximately $800-$15,000, while multi-cylinder hydraulic large-sized machines (500-1000 tons/hour) cost approximately $5,000-$65,000. When selecting a cone crusher, you need to consider a variety of factors based on your crushing needs. First, clarify your crushing requirements, including the hardness, moisture content, mud content, and abrasiveness of the material you need to process. For example, for medium-hard or weathered ores, a single-cylinder hydraulic crusher is recommended; for high-hardness ores, a multi-cylinder hydraulic cone crusher is recommended, while for medium-hard materials with abrasive properties, a compound cone crusher is required. Because material properties directly determine the equipment type and output particle size, hourly processing capacity is key to selecting equipment size and power.

Cone Crusher Price Table (for reference only)

|

Item Model |

Feeding capacity (t/h) | Maximum number of particles allowed for an object (mm) | Power (w) | Voltage (v) | Current (a) | Double amplitude (mm) | Gap (mm) | Total weight (kg) | Price |

| GZ1 | 5 | 50 | 60 | 220 | 1≤ | 1.75 | 1.9-2.2 | 75 | $800-$40000 |

| GZ2 | 10 | 60 | 150 | 220 | 2.3≤ | 1.75 | 1.9-2.2 | 155 | $8500-$65000 |

| GZ3 | 25 | 70 | 200 | 220 | 3.8≤ | 1.75 | 1.9-2.2 | 225 | $14000-$98000 |

| GZ4 | 50 | 100 | 450 | 220 | 7≤ | 1.75 | 1.9-2.2 | 460 | $22000-$170000 |

| GZ5 | 100 | 150 | 650 | 220 | 10.6≤ | 1.75 | 1.9-2.2 | 656 | $35000-$210000 |

How does the model affect the Cone Crusher price?

Cone Crusher price will vary according to different models. Different models have different crushing materials and manufacturing processes. Cone Crusher mainly has three types: single-cylinder hydraulic, multi-cylinder hydraulic and compound. Among them, the single-cylinder hydraulic cone crusher has the simplest structure and the cheapest price, about US$800-60,000. Its discharge particle size can be controlled at 6-25mm, and it is commonly used for crushing medium-hard materials such as limestone, dolomite, and sandstone; the multi-cylinder hydraulic cone crusher costs between US$5,000 and US$20,000, with a maximum output of up to 1,200 tons. The feed particle size is 53-375mm (suitable for coarse crushing) and the discharge particle size is controlled at 10-38mm. It is commonly used for crushing high-hardness iron ore, quartzite, basalt, and medium-hard river pebbles, coal gangue, etc. The compound cone crusher has the highest price, about US$30,000-210,000. It uses a combination of spring and hydraulics, and the cavity type can be adjusted to coarse/medium/fine/ultrafine according to the material, with a processing capacity of 37-570 tons/ It is often used for crushing limestone, coal, gypsum and abrasive construction waste with compressive strength ≤ 250MPa.

| Model | Type | Power (kW) | Processing capacity (t/h) | Price range (US dollars) | Applicable materials |

| HPS200 | Multi-cylinder hydraulic | 132-200 | 90-250 | 15,000-25,000 | Granite, basalt |

| HPT300 | Multi-cylinder hydraulic | 250 | 110-380 | 55,000-75,000 | Hard rock, ore |

| PYF1300 | Composite | 160 | 109-358 | 80,000-120,000 | Medium hardness ore |

| DG100 | Single cylinder hydraulic | 90 | 27-170 | 8,000-15,000 | Limestone, construction waste |

| PYF-1600 | Composite | 250 | 90-635 | 150,000-210,000 | Various hard ores |

How does crushing volume affect cone crusher price?

Cone crusher price is also affected by the volume of crushing. This is because different crushing volumes require different motor power and equipment models. For example, small equipment with a processing capacity of less than 100 tons/h and equipped with a 75kW motor costs between US$800 and US$30,000. Equipment with a processing capacity of 100-300 tons/h and equipped with a 90kW-200kW motor costs between US$5,000 and US$80,000. Large equipment with a processing capacity of 300 tons/h or more and equipped with an 18kW-400kW motor costs even more, ranging from US$10,000 to US$210,000.

What influence do materials and manufacturing processes have on cone crusher price?

Cone crusher price can vary depending on materials and manufacturing processes. High-quality materials can extend equipment life, but also increase costs. Using wear-resistant steel can increase liner life by 30-50%, but also increases price by 15-25%. High-manganese steel (ZGMn13) is generally used for the crushing chamber. It is relatively inexpensive and cost-effective, suitable for crushing non-abrasive materials. For highly abrasive materials such as granite and basalt, wear-resistant alloys are required. These materials have a hardness of HRC60 or higher and a lifespan 3-5 times that of manganese steel, though they cost 30-50% more. Precision casting processes can also reduce failure rates, but also increase costs by 10-20%. Furthermore, high-end hydraulic systems are 2-3 times more expensive than standard systems.

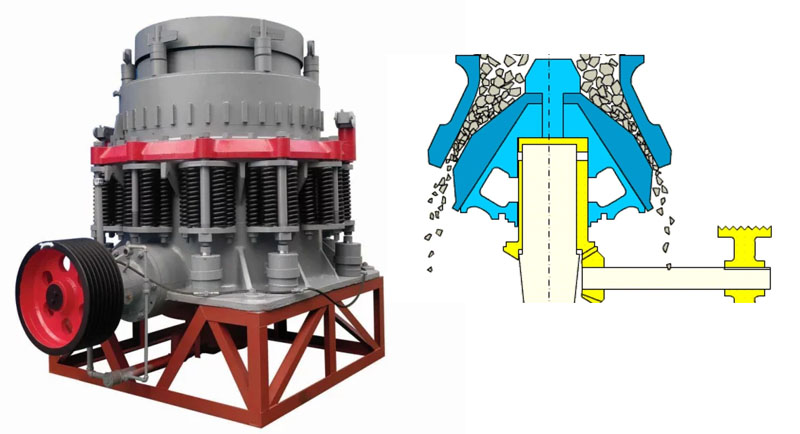

How does the working principle affect the Cone Crusher Price?

Cone Crusher uses different large and small models, and the accessories inside may be different. Its working principle is also different, and the price is naturally different. Among them, the hydraulic cone crusher uses an electric motor to drive a hydraulic motor through a hydraulic pump to drive the movable cone to rotate and swing. The hydraulic cylinder automatically adjusts the position of the fixed cone to control the discharge particle size. If it encounters foreign objects such as iron blocks, the hydraulic cylinder will automatically lift the fixed cone to discharge the material without stopping. Due to its degree of automation, its price is relatively expensive, generally between $50,000 and $200,000. When the ordinary cone crusher without a hydraulic cylinder is working, the motor drives the eccentric shaft sleeve through a pulley and gear to make the movable cone rotate and swing to crush. If it encounters foreign objects, it needs to stop, but its price is relatively cheap, generally between $5,000 and $80,000.

How does the manufacturer affect cone crusher prices?

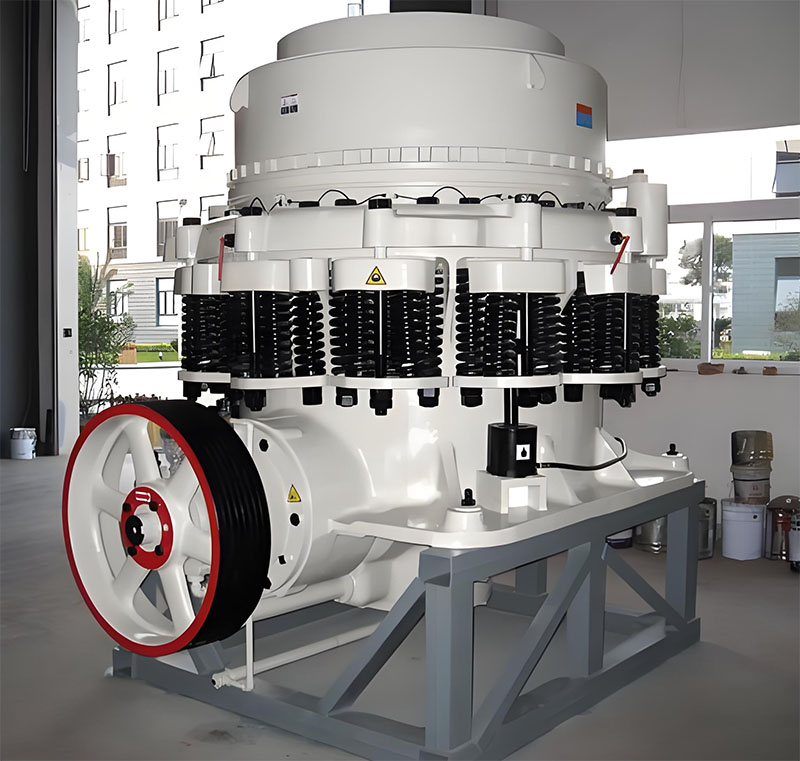

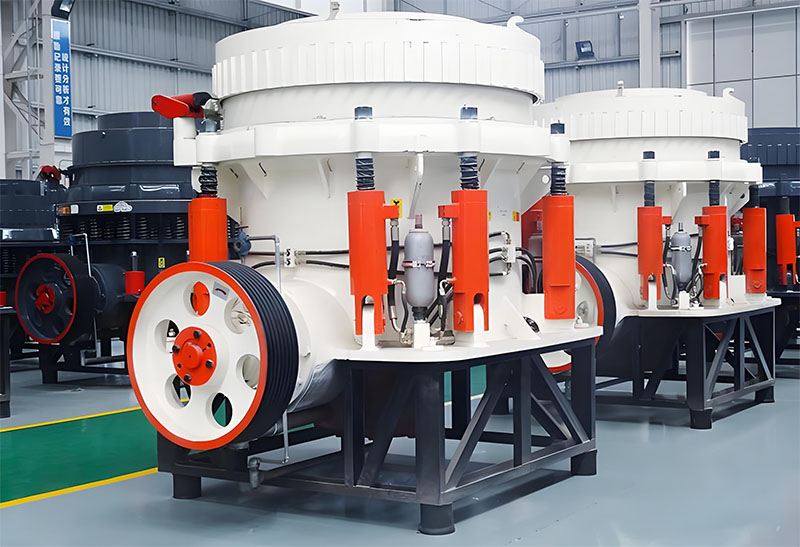

Cone crusher prices vary by manufacturer. Cone crusher models, materials, and production processes vary, leading to slight price differences. At Machrise, we offer a variety of equipment, including single-cylinder hydraulic cone crushers, multi-cylinder hydraulic cone crushers, automatic cone crushers, spring cone crushers, Depan cone crushers, demountable cone crushers, and standard cone crushers. We sell directly from the manufacturer, with prices starting as low as $800. We can also customize our products to meet your crushing needs or add various features.

Cone Crusher price will vary according to the equipment model, material, and processing capacity. When choosing, please consider the hardness, abrasiveness, corrosiveness, etc. of the material, the particle size of the discharge port, the required output, the product material, and whether customization is required. Only in this way can you choose the most cost-effective equipment. Cone Crusher processing capacity is 30-1500t/h, the feed particle size is 50-460mm, and the discharge particle size is 8-65mm. It can also be customized to meet more crushing requirements.

Minerals Coarse Crusher

Minerals Coarse Crusher