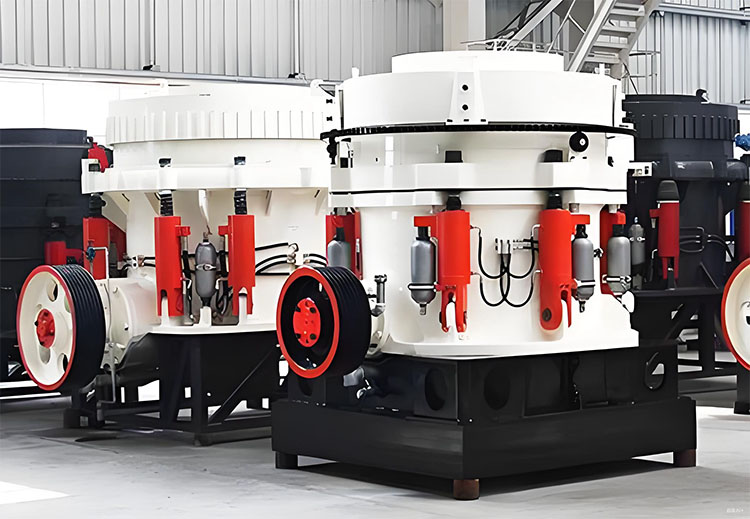

Super Fine Crushing Cone Crusher

Saturday November-08 2025 17:03:41

Super Fine Crushing Cone Crusher uses the principle of lamination crushing to further refine medium and coarse materials into ultrafine particles, suitable for high-precision production needs. It can perform ultrafine crushing, grading crushing, and stable output, with high efficiency and uniform particle shape. It can crush medium and high hardness materials such as granite, basalt, limestone, and quartz, and is also suitable for brittle materials such as ores, rocks, and metallurgical slag. The feed particle size is usually 30-80mm, and the output particle size can be precisely controlled within 0.075-5mm, with a crushing capacity of 10-200t/h.

What are the classifications of Super Fine Crushing Cone Crusher?

Super Fine Crushing Cone Crushers are mainly divided into two categories: single-cylinder hydraulic and multi-cylinder hydraulic. Single-cylinder hydraulic models are compact and easy to maintain, adjusting the discharge port through a single-cylinder hydraulic system, making them suitable for small to medium-scale production. Multi-cylinder hydraulic models employ multi-cylinder coordinated control, resulting in more uniform crushing force, more precise particle shape control, and stronger stability, making them suitable for large-scale, high-hardness material crushing scenarios. The core differences between the two lie in structural complexity, adjustment precision, and applicable production capacity. Single-cylinder models are mostly suitable for 10-80t/h capacity requirements, while multi-cylinder models are geared towards large-scale production of 80-200t/h.

What are the advantages of the Super Fine Crushing Cone Crusher?

The Super Fine Crushing Cone Crusher precisely crushes materials to a fineness of 0.075mm. Utilizing a layered crushing principle, its crushing chamber is designed to meet ultrafine grinding requirements. Materials undergo multiple compressions and grinding processes within the chamber, resulting in highly uniform, well-graded finished particles free of excessively large impurities. While ensuring ultrafine grinding performance, it significantly reduces energy consumption compared to traditional fine crushing equipment. Furthermore, its wear-resistant parts are made of high-strength materials, resulting in low wear, long service life, and reduced maintenance costs. In addition, it is highly adaptable, capable of handling materials of varying hardness such as granite, limestone, and quartz sand. It is easily adjustable and can flexibly adapt to different ultrafine grinding conditions.

How does the Super Fine Crushing Cone Crusher work?

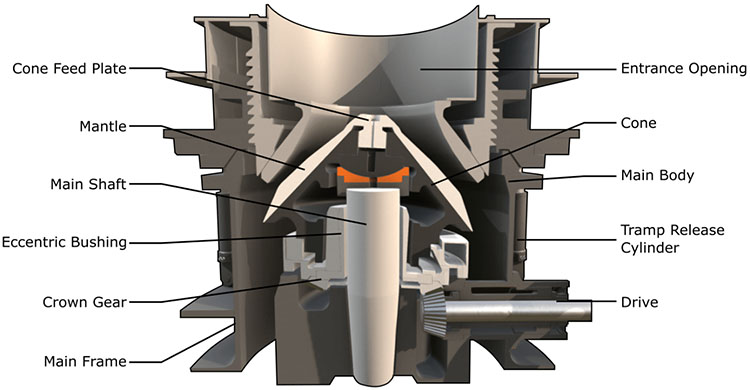

The Super Fine Crushing Cone Crusher is powered by an electric motor, which drives an eccentric sleeve to rotate via a pulley and drive shaft. This eccentric sleeve then drives a moving cone to oscillate around the axis of a fixed cone. A gradually narrowing ultrafine crushing chamber is formed between the moving and fixed cones. After the material enters the chamber from the top feed inlet, it is subjected to a combination of compression, shearing, and grinding as the moving cone periodically approaches and moves away from the fixed cone. As the crushing chamber gradually narrows from top to bottom, the material is repeatedly crushed to the required ultrafine particle size and finally discharged through the bottom discharge outlet. The equipment controls the finished particle size by adjusting the size of the discharge outlet. Its layered crushing principle ensures crushing efficiency while reducing over-crushing of materials, making it suitable for ultrafine crushing operations on various types of hard rock.

Super Fine Crushing Cone Crusher Parameters

|

Item Model |

Feeding capacity (t/h) | Maximum number of particles allowed for an object (mm) | Power (w) | Voltage (v) | Current (a) | Double amplitude (mm) | Gap (mm) | Total weight (kg) |

| GZ1 | 5 | 50 | 60 | 220 | 1≤ | 1.75 | 1.9-2.2 | 75 |

| GZ2 | 10 | 60 | 150 | 220 | 2.3≤ | 1.75 | 1.9-2.2 | 155 |

| GZ3 | 25 | 70 | 200 | 220 | 3.8≤ | 1.75 | 1.9-2.2 | 225 |

| GZ4 | 50 | 100 | 450 | 220 | 7≤ | 1.75 | 1.9-2.2 | 460 |

| GZ5 | 100 | 150 | 650 | 220 | 10.6≤ | 1.75 | 1.9-2.2 | 656 |

What are the structural components of the Super Fine Crushing Cone Crusher?

The Super Fine Crushing Cone Crusher consists of a frame, transmission device, eccentric sleeve, crushing cone, adjustment device, safety device, and lubrication system. The frame is a welded integral structure, providing stable support. The transmission device includes a motor, pulleys, and drive shaft, providing power for crushing. The eccentric sleeve drives the crushing cone to rotate eccentrically, forming a gradually changing crushing chamber with the fixed crushing wall, achieving ultra-fine crushing of materials. The adjustment device can precisely adjust the discharge port size to control the output particle size; the safety device automatically relieves pressure in case of overload, protecting the equipment from damage. The lubrication system uses circulating oil to cool and reduce friction in key parts such as the transmission components and eccentric sleeve.

What are the applications of the Super Fine Crushing Cone Crusher?

The Super Fine Crushing Cone Crusher is widely used in mining, building materials production, metallurgical smelting, chemical raw material processing, and construction waste recycling. It is particularly suitable for scenarios requiring fine and ultrafine crushing of materials, such as manufactured sand production, pretreatment before ore beneficiation, and fine processing of industrial raw materials. It can efficiently crush medium-hard to extra-hard materials with a Mohs hardness of 5-16, including natural ores such as granite, basalt, limestone, quartz, iron ore, marble, diabase, and dolomite. It can also process recycled materials such as concrete aggregate, steel slag, and coal gangue. The crushed product has uniform particle size and a high pass rate.

Coarse crusher

Coarse crusher Minerals Coarse Crusher

Minerals Coarse Crusher  Cone Crusher

Cone Crusher