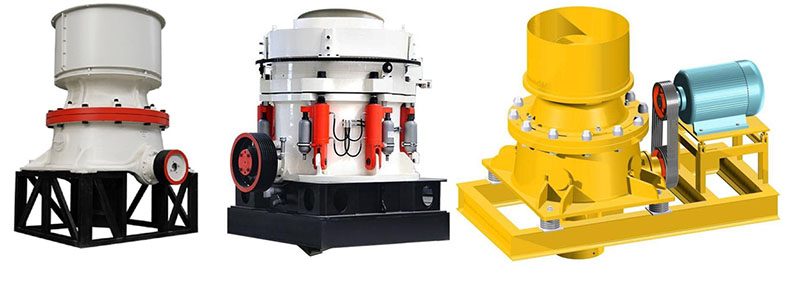

Cone Crusher Manufacturers

Thursday October-30 2025 17:48:32

Different cone crusher manufacturers produce slightly different models and specifications of cone crushers, but their primary function is to crush large pieces of ore or rock into the desired particle size. However, the crushing capacity, feed size, and discharge size vary from manufacturer to manufacturer. Some manufacturers offer crushing capacities of 100, 200, or 500 tons/hour, so it's crucial to choose a manufacturer that can provide customized products. The cone crushers we produce have a maximum processing capacity of up to 1,000 tons/hour, a feed size range of 50-300 mm, and an adjustable discharge size between 5 and 100 mm. Most importantly, in addition to standard models, we can also provide customized products based on different material characteristics, such as mobile models, equipped with water spray dust suppression devices, iron removal devices, and more.

How to Choose a Model Based on Cone Crusher Manufacturers?

Cone crusher manufacturers offer a variety of models, including single-cylinder hydraulic, multi-cylinder hydraulic, fully hydraulic, spring, and compound types. When choosing a model, it's important to first understand the material's hardness, moisture content, viscosity, abrasiveness, and final particle size, as these factors directly determine the equipment's crushing chamber type. Hourly crushing capacity is crucial for selecting the equipment's model and dimensions. Different types of materials typically require different machine models and crushing mechanisms.

Single-cylinder hydraulic Cone Crusher: There is only one large hydraulic cylinder at the bottom of the moving cone, which mainly plays the role of support, automatic adjustment of the discharge port and iron overload protection. It has a simple structure and is easy to maintain. It is suitable for medium and fine crushing of medium-hard materials. It has a power of 315kW and a processing capacity of 100-1000t/h.

Multi-cylinder hydraulic Cone Crusher: Multiple hydraulic cylinders are arranged around the base of the moving cone, delivering 2-3 times the crushing force of a single cylinder. Suitable for high-hardness ores (such as granite and basalt), they offer power outputs ranging from 160-630kW and outputs from 500-2000t/h. The finished product is of excellent shape, with a high percentage of particles under 8mm. This multi-cylinder design is commonly used in metal mines and sand and gravel aggregate production lines.

Fully hydraulic Cone Crusher: Representative model HXGYS, fully hydraulically driven, with a high degree of automation, can realize coarse, medium and fine crushing conversion. Processing capacity 36-650t/h, closed-side discharge port particle content of 80%, good energy saving effect. Especially suitable for sand making operations with strict requirements on product particle size.

Composite Cone Crusher: PSGB1626 and other models combine spring and hydraulic technology, economical price and simple maintenance. Power 220kW, capacity 90-635t/h, high cost performance in the treatment of medium and low hardness materials7. Although gradually replaced by hydraulic models, it is still used in specific fields.

What are the advantages of Cone Crusher Manufacturers?

Each cone crusher manufacturer produces a variety of equipment with distinct advantages. Cone crushers can crush materials ranging from medium-hard limestone to extremely hard granite, basalt, and iron ore. However, some manufacturers only produce single-cylinder hydraulic cone crushers for medium-hard materials, while others produce multi-cylinder hydraulic cone crushers for medium-to-high-hardness materials. However, all equipment utilizes high-strength linings such as ZGMn18Cr2, resulting in a service life 3-5 times that of ordinary materials. Through the mutual compression and crushing of materials, the finished product has a high cubic ratio, reduces flaky particles, and improves aggregate quality. An intelligent control system monitors the equipment's operating status in real time, automatically adjusting the discharge opening and load, and reducing manual intervention. Furthermore, the rational cavity design effectively reduces energy consumption, and the fully enclosed structure minimizes dust spillage.

Cone Crusher Manufacturers Product Specifications

Cone Crusher Manufacturers produces CZS series cone crushers in a wide variety of specifications and models. Different models differ in processing capacity, feed size and power, and the crushing cavity type needs to be selected according to the material properties.

| Model | Cavity Type | Maximum Feed Size | Discharge Opening Adjustment Range | Processing Capacity | Motor Power | Machine Weight | External Dimensions | Estimated Price Range |

| CZS36B | Slim Type | 85 | 9-22 | 45-91 | 75 | 14.5 | 2656×1746×2410 | $800-$30,000 |

| CZS36B | Thick | 150 | 13-38 | 59-163 | 75 | 14.5 | 2656×1746×2410 | $8,000 -$30,000 |

| CZS36B | Extra thick type | 152 | 25-38 | 118-163 | 75 | 14.5 | 2656×1746×2410 | $8,000 - $30,000 |

| CZS36D | Slim type | 35 | 3-13 | 27-90 | 110 | 15 | 2656×1746×2410 | $1,500 - $30,000 |

| CZS36D | Medium | 65 | 5-16 | 36-100 | 110 | 15 | 2656×1746×2410 | $1,000 - $30,000 |

| CZS51B | Slim type | 115 | 13-31 | 109-181 | 160 | 26.5 | 2958×2354×3156 | $2,000 - $60,000 |

| CZS51B | Medium | 178 | 16-38 | 132-253 | 160 | 26.5 | 2958×2354×3156 | $2,000 - $60,000 |

| CZS51B | Thick | 205 | 19-51 | 172-349 | 160 | 26.5 | 2958×2354×3156 | $2,000 - $60,000 |

| CZS51B | Extra thick type | 220 | 25-51 | 236-358 | 160 | 26.5 | 2958×2354×3156 | $2,000 - $60,000 |

| CZS51D | Slim type | 54 | 3-16 | 36-163 | 200 | 27 | 2958×2354×3156 | $3,000 - $70,000 |

| CZS51D | Medium | 76 | 6-16 | 82-163 | 200 | 27 | 2958×2354×3156 | $3,000 - $70,000 |

| CZS66B | Slim type | 178 | 16-38 | 181-327 | 220 | 51 | 3941×2954×3771 | $4,000 - $90,000 |

How does the equipment produced by Cone Crusher Manufacturers work?

While different cone crusher manufacturers produce varying models, their operating principles remain the same: material is crushed by the interplay of a fixed cone and a moving cone. After entering through the top feed port, the material passes through a distribution plate and evenly falls into the crushing chamber formed by the fixed and moving cones. Driven by an eccentric shaft sleeve, the moving cone performs a periodic oscillating motion around the machine's central axis, sometimes approaching the fixed cone, crushing the material through compression and shearing forces, and sometimes moving away, allowing the crushed material to move downward under gravity. After repeated crushing, the material reaches the desired particle size and is discharged from the bottom discharge port, which is adjustable to control the final particle size.

MACHRISE Cone Crusher Manufacturers offers a comprehensive range of cone crushers, capable of efficiently crushing medium-hard and high-hardness granular and bulk materials at varying crushing capacity requirements. We also offer customized mobile cone crushers for different application scenarios and specific crushing process requirements, suitable for crushing materials at various work locations. In areas with limited or no electricity, diesel-powered cone crushers are also available, allowing them to operate without electricity. All cone crushers are constructed of high-manganese steel, offering wear resistance and a long lifespan. They can also be equipped with de-ironing devices, silencers, and PLC intelligent operating systems.

Minerals Coarse Crusher

Minerals Coarse Crusher