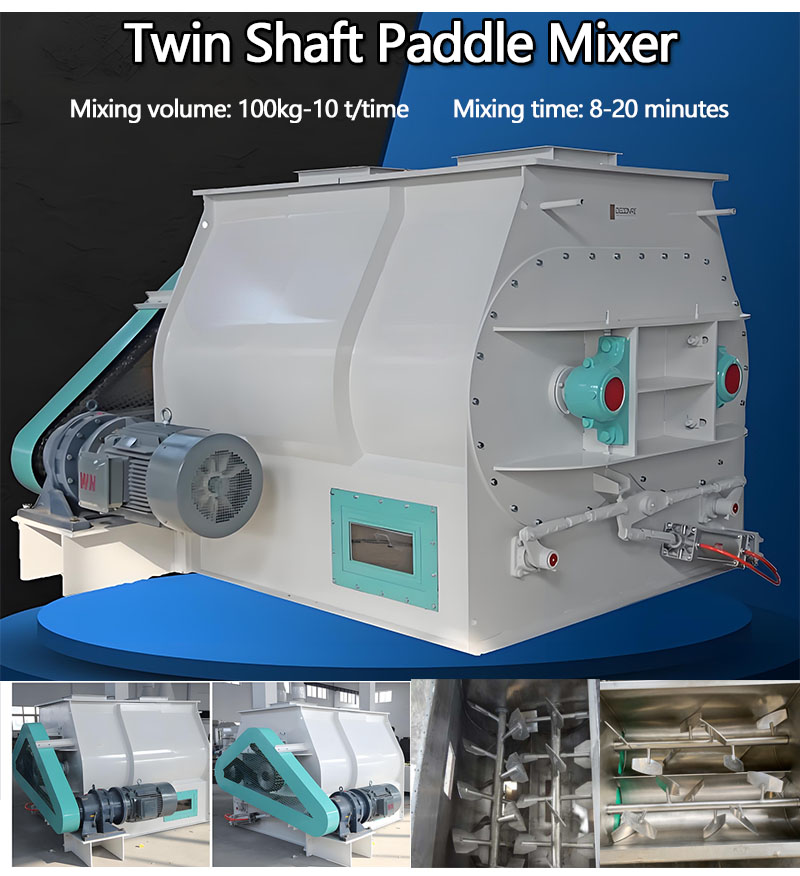

Twin Shaft Paddle Mixer

It stirs and mixes powders, granules, liquids, and slurries by rotating two propeller blades in opposite directions. The price range is $1000-$15,000.

One-time mixing: 100kg-10 tons

Mixing time: 8-20min

Voltage: 220V/380V/customize

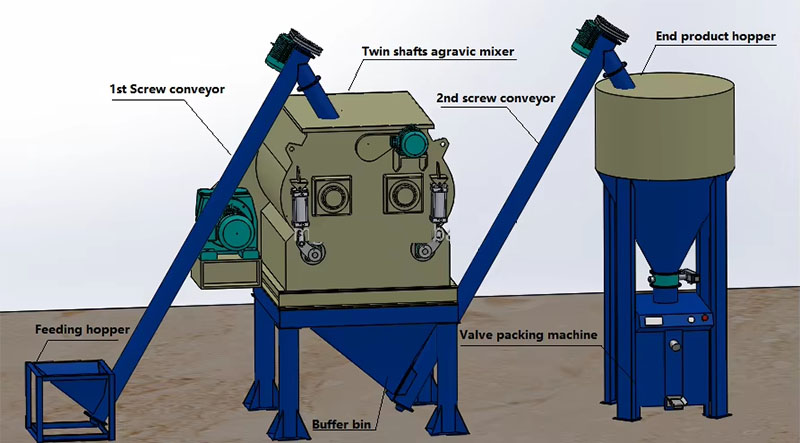

Feeding method: manual feeding, automatic feeding or other methods

What is a Twin Shaft Paddle Mixer?

A Twin Shaft Paddle Mixer is an industrial mixer that efficiently mixes different types of materials. Its counter-rotating twin-shaft paddle blades achieve efficient mixing, shearing, tumbling, and pushing the materials, breaking up any agglomerates and ensuring uniform blending of the different ingredients. It can precisely mix powders, granules, or pastes, and can also simultaneously perform light crushing, heating, or humidification. Its mixing capacity ranges from 100 kg to 10 tons, and its mixing time is adjustable based on the material properties, typically between 5 and 20 minutes.

The Twin Shaft Paddle Mixer's body and paddles are made of powdered carbon steel, stainless steel, or a special wear-resistant alloy. The paddles are available in spiral or straight styles. Spiral paddles are preferred for viscous materials, while straight paddles are preferred for granular materials. You can choose the type based on the material properties, and we also offer customized products.

What types of Twin Shaft Paddle Mixers are there?

Twin Shaft Paddle Mixers are available in horizontal and vertical models. They vary in the materials they mix and their applications. You can choose the model that best suits your needs, with horizontal models being the most common.

Horizontal Twin Shaft Paddle Mixers: Featuring a horizontally configured twin-shaft design, they are suitable for mixing dry powders, granules, and low- to medium-viscosity materials. They are suitable for premixing additives in feed mills and mixing powders in the chemical industry, with batch sizes ranging from 250 kg to 6,000 kg.

Vertical Twin Shaft Paddle Mixers: Featuring a vertical shaft structure, they excel at handling high-viscosity materials such as paints and inks. Their vertical circulation design reduces the risk of clogging, but their efficiency is slightly lower than that of horizontal models, making them more suitable for small-batch, fine-grained mixing.

What types of materials can a Twin Shaft Paddle Mixer mix?

The Twin Shaft Paddle Mixer can be used in all applications requiring solid-solid or solid-liquid mixing, and is suitable for mixing various types of materials and raw materials:

Powder-to-powder mixing: This is the most common application, such as feed premixes, food additives, pharmaceutical powders, and chemical raw materials.

Particle-to-particle mixing: Examples include plastic granules, compound fertilizers, and feed pellets.

Powder-to-particle mixing: For example, adding powdered nutritional supplements to feed pellets.

Powder/particle mixing with a small amount of liquid: Equipped with a spray dosing system, it can evenly add and mix liquids such as molasses, oil, and water, such as in the production of molasses-enriched feed or humidified chemical materials.

What are the advantages of the Twin Shaft Paddle Mixer?

The Twin Shaft Paddle Mixer utilizes dual counter-rotating shafts to create intense convection, significantly reducing mixing time by nearly half compared to traditional equipment at the same production capacity. For example, a single-shaft Paddle Mixer can complete a batch of construction mortar in 8-10 minutes, while a twin-shaft mixer can complete the process in 15 minutes. It also efficiently handles a wider range of materials, from powders with viscosities <5,000 centipoise to pastes >10,000 centipoise, and from solid-solid mixing to highly filled solid-liquid systems with a powder content >60%. It also eliminates the "floating and clumping" problem often associated with single-shaft equipment. Operating costs are also improved, with a variable frequency motor and efficient mixing structure reducing energy consumption by 20% compared to traditional equipment. The highly wear-resistant blade design extends the life of consumable parts and reduces maintenance downtime. It also offers greater process scalability, allowing integration of heating/cooling jackets, spray devices, and vacuum systems to meet specialized requirements such as pharmaceutical clean mixing and temperature-controlled mixing of hot-melt adhesive powders—functions difficult to achieve with single-shaft equipment.

How does the Twin Shaft Paddle Mixer work?

When the Twin Shaft Paddle Mixer is activated, the staggered paddles on the two shafts rotate synchronously in opposite directions. The intense convection and shear forces generated by this rotation break up material agglomerates at the blade edges. The thrust of the paddles then tumbles and pushes the material along the chamber walls, creating a circulating convection flow within the mixing chamber and preventing uneven mixing. The continuously counter-rotating paddles gradually achieve a uniform mixing of the materials. Finally, the paddles' thrust and gravity combine to discharge the materials from the bottom outlet of the mixing chamber, completing the mixing process.

Twin Shaft Paddle Mixer Specifications

| Model | Volume(m³) | One-time mixing(kg) | Motor power(kw) | Weight(kg) |

| WZL-1 | 1 | 300-500 | 7.5-11 | 1600 |

| WZL-2 | 2 | 600-1000 | 11-15 | 2300 |

| WZL-3 | 3 | 1000-1500 | 18.5-22 | 2900 |

| WZL-4 | 4 | 1200-2000 | 22-30 | 4800 |

| WZL-5 | 5 | 1800-3000 | 30-37 | 6000 |

What are the applications of the Twin Shaft Paddle Mixer?

The Twin Shaft Paddle Mixer can be used to stir and mix different types of materials, achieving a uniform blend. It is suitable for powders, granules, liquids, and materials with low specific gravity and varying particle sizes.

Chemical Industry: Pigments, dyes, plastics, additives, fertilizers, etc. Food Industry: Milk powder, chicken essence, flour, food additives, chocolate raw materials, etc.

Pharmaceutical Industry: APIs, intermediates, pharmaceutical excipients

Feed Industry: Premixes, livestock and poultry feed, aquatic feed, feed additives

Building Materials Industry: Dry mortar, refractory materials, ceramic glaze, glass raw materials, thermal insulation mortar, anti-crack mortar

Twin Shaft Paddle Mixer Customer Cases

| Customer Industry | Application Scenarios | Mixing Materials | Mixing Volume (m³/hour) | Mixing Time (minutes) | Core Values |

| Building Materials | Dry-Mix Mortar Production | Cement, Quartz Sand, Polymer Additives | 25 | 8 | Continuous mixing meets mortar uniformity requirements, with 40% higher efficiency than traditional equipment |

| Chemical Industry | Pigment Premix Preparation | Organic pigments, titanium dioxide, calcium carbonate filler | 12 | 10 | Solve the mixing challenges of materials with high specific gravity differences, achieving 98% uniformity in active ingredient distribution |

| Food Additives | Colorant Premix | Tartrazine, maltodextrin carrier | 6 | 7 | The color difference value is controlled within 0.5, meeting the high-end baking color standard |

| Feed processing | Organic poultry feed production | Grain flour, vitamin premix, oil | 10 | 6 | Mix uniformity CV value reduced to 2%-3%, increasing production capacity by 20% |