Conical twin screw mixer

The mixing, homogenization, dispersion and wetting reaction of different materials are achieved through the rotation of two asymmetric, parallel conical screws. The price is between $1,500 and $15,000

Mixing capacity: 100-6000 kg/time

Mixing time: 8-20min

Capacity: 100L-5000L (larger sizes available on request)

Discharge methods: Manual, pneumatic, or electric ball or butterfly valves; special designs such as spherical valves (to reduce residue)

Customizations: Heating/cooling jackets (steam, thermal oil, hot water), spray nozzles (for adding small amounts of liquid), vacuum or pressure operation

What is a Conical Twin Screw Mixer?

A Conical Twin Screw Mixer is a conical-shaped mixer with two screws that create turbulence, shear, and convection, achieving uniform mixing and reducing stratification. It can be used to mix powders, granules, and liquids, as well as highly viscous or paste-like materials. It can also handle materials with widely varying specific gravities or uneven particle size distributions. It is commonly used for material pretreatment, finished product mixing, and formulation, with mixing capacities ranging from 50 to 6,000 kg per cycle.

Conical twin screw mixers offer capacities of 100L, 500L, 1000L, 2000L, and 5000L. Materials include carbon steel and stainless steel, and special treatments such as polishing and Teflon coating are also available. We also offer customized mixing solutions for different material properties, including explosion-proof models (for mixing flammable and explosive powders), heating/cooling jackets (for temperature control), and vacuum models (suitable for easily oxidized materials). Please contact our online customer service for more information.

What types of conical twin screw mixers are there?

| Type | Material Type | Mixing Volume (Per Mix) | Features |

| Standard Type | Suitable for all types of dry powders and granules, especially suitable for materials with large specific gravity differences and large mixing ratios | 50kg-6000kg | High mixing accuracy (uniformity CV <5%), fast mixing speed, low energy consumption, and no bottom bearing to avoid contamination and malfunctions |

| Heavy Duty (High Power) |

High-density materials (such as metal powders, mineral powders), slightly damp or liquid-containing powders |

100-6000kg | Increased motor power and enhanced spiral structure can handle greater loads and resistance |

| Flying Knife Spray Type | Solid-liquid mixing (requires liquid addition), materials prone to agglomeration or requiring reaction | 100-6000kg | Equipped with a high-speed flying knife to break up agglomerated materials, and a spray device to evenly add liquid, achieving simultaneous mixing and reaction |

| Pressure/Vacuum Type | Materials that are flammable or explosive, require oxygen isolation, or require removal of volatiles/moisture during the mixing process | 100-6000kg | The cone can be sealed for pressurization or vacuum to meet special process requirements and enhance safety |

What are the advantages of the Conical twin screw mixer?

The Conical twin screw mixer utilizes a twin-screw blade design, effectively preventing material stratification and segregation, ensuring uniform mixing. Mixing uniformity can reach over 99% in just 5-30 minutes, over 40% faster than traditional equipment. Even materials with significantly different specific gravities (such as plastic powder and metal powder) can achieve over 99% uniformity. Its fully enclosed structure prevents cross-contamination, and its mirror-polished interior (Ra ≤ 0.8μm) eliminates sanitary blind spots. It can stably process powders ranging from ultrafine powders (particle size 0.1μm) to small particles (≤ 5mm), and from low moisture content (≤ 1%) to high humidity (≤ 20%). It is particularly suitable for resolving mixing challenges associated with high agglomeration, airflow, and materials with widely varying specific gravities.

How does the Conical twin screw mixer work?

When a conical twin screw mixer is in operation, material first enters the drum through the top feed port. The two internal screws then rotate around their axes, simultaneously orbiting along the drum's conical surface. As the screws rotate, they convey the material from the bottom upward. Once at the top, the material is dispersed by gravity. Simultaneously, the clearance between the screws and the drum wall, combined with the synergistic action of the twin screws, creates shear, convection, and diffusion effects on the material, breaking up material agglomerates and promoting uniform mixing. Once mixing is complete, the material is discharged through the bottom discharge valve.

Conical twin screw mixer specifications

What are the applications of conical twin screw mixers?

Conical twin screw mixers can be used to mix a variety of materials, including powders, granules, and liquids. They are commonly used in a variety of industries, including the chemical, food, pharmaceutical, building materials, and feed. They are used for formulating chemical powders, premixing food ingredients, uniformly mixing pharmaceutical powders, mixing building material granules, and mixing feed ingredients. It can mix a wide variety of materials, including various powders (such as calcium carbonate powder, flour, and traditional Chinese medicine powders), granules (such as plastic masterbatch, compound fertilizer granules, and mineral granules), and low-viscosity slurries (such as ceramic slurries, paint premixes, and jam premixes), meeting various mixing needs.

Optional Configurations of the Conical Twin Screw Mixer

The Conical Twin Screw Mixer can be customized based on the application scenario and mixing materials:

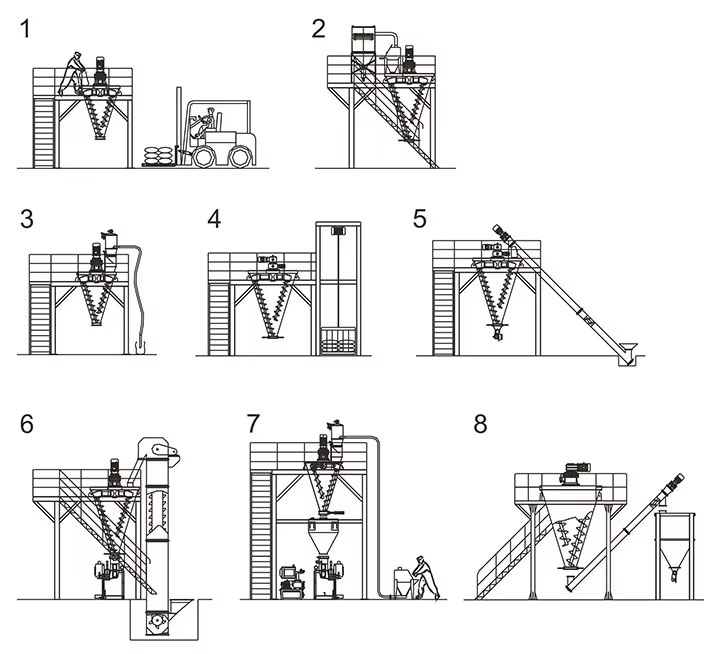

Configuration 1: Conical mixer with manual feed

Configuration 2: Conical mixer with manual feed and dust collector

Configuration 3: Conical mixer with vacuum feeder

Configuration 4: Conical mixer with crane

Configuration 5: Conical mixer with screw conveyor

Configuration 6: Conical mixer with bucket elevator

Configuration 7: Simple production line with conical mixer, vacuum feeder, storage tank, and automatic packaging machine. Configuration 8: Simple production line with conical mixer, manual feeding, screw conveyor to storage tank, and automatic packaging

Conical twin screw mixer case

| Application Scenarios | Mixing Materials | Capacity | Mixing Amount | Mixing Time |

| Chemical Raw Materials Production | Calcium Carbonate Powder + Resin Granules | 1000L | 800kg | 15 Minutes |

| Food Processing Plant | Flour + Food Additives | 500L | 400kg | 10 minutes |

| Pharmaceutical Preparation Workshop | Traditional Chinese Medicine Powder + Excipients | 800L | 600kg | 20 minutes |

| Building Materials Manufacturing Enterprise | Tile Adhesive Raw Materials (Cement + Quartz Sand) | 2000L | 1600kg | 25 minutes |