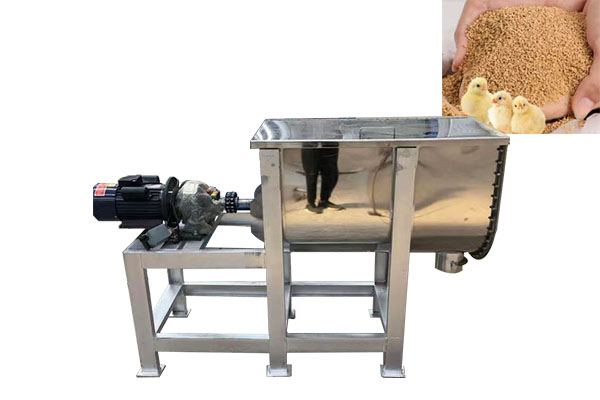

Granules and liquids continuous mixer

It can be used for continuous feeding, mixing and discharging of granular and liquid materials to fully mix the solid and liquid, such as flour + water; the price is $900.00-$9,000.00

Mixing capacity: 100-250,000 L/h

Maximum feed rate: 50-11,200 kg/h

Mixing time: 5-15min

Power: 2.2-75 kW

What is a granules and liquids continuous mixer?

A granules and liquids continuous mixer is a continuous mixer used to efficiently and uniformly mix solid particles with liquids. The rotation of spiral blades or paddles disrupts the natural separation of solids and liquids, achieving precise mixing of granules with slurries, oils, or viscous liquids, ensuring a uniform mix. It can be used to mix materials such as flour and water, milk powder and syrup (food), pigment granules and solvents (chemical), and pharmaceutical powders and liquids (pharmaceutical). It uses a dual-feed system to continuously feed the materials separately. Once entering the mixing chamber, the materials are stirred in real time by the spiral or paddles. After mixing, the materials are continuously discharged directly. The mixing capacity ranges from 50 kg to 5 tons. Materials are available in 304 or 316L stainless steel.

What types of granules and liquids continuous mixers are there?

Granules and liquids continuous mixers are available in three models: fine-grain, low-viscosity, medium-grain, medium-viscosity, and coarse-grain, high-viscosity. You can choose the appropriate model based on the specific characteristics of the particles and liquids being mixed. You can also contact our online customer service for model recommendations.

| Model Classification | Compatible Particle Characteristics | Compatible Liquid Characteristics | Typical Application Scenarios |

| Fine Particle and Low Viscosity Liquid Type | Particle size 0.1-2mm (such as flour, protein powder, cement powder), no obvious agglomeration | Liquid viscosity ≤500mPa・s (such as water, alcohol, dilute nutrient solution) | Meal replacement powder premixes for the food industry, cement admixture blends for the building materials industry |

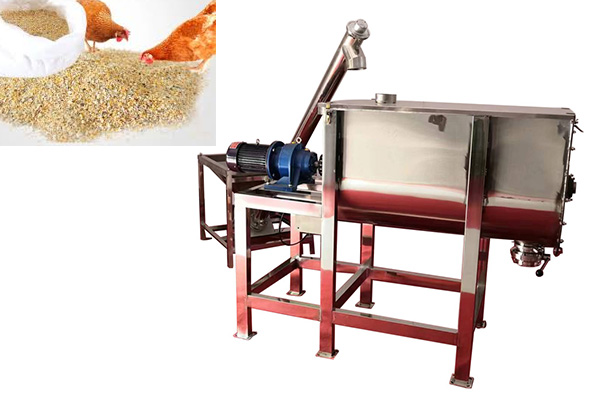

| Medium-grained, medium-viscosity liquid | Particle size 2-5mm (such as feed pellets, fertilizer pellets), slight agglomeration | Liquid viscosity 500-1500mPa・s (such as vegetable oil, medium-concentration resin) | Agricultural feed oil and fat additives, pigment and solvent blends for the chemical industry |

| Coarse-grained, high-viscosity liquid | Particle size 5-10mm (such as plastic particles, mineral particles), prone to agglomeration | Liquid viscosity 1500-3000mPa・s (such as lubricating oil, high-concentration adhesives) | Masterbatch preparation in the plastics industry, mineral powder and reagent mixing in the mining industry |

Why choose a granulules and liquids continuous mixer?

A granulules and liquids continuous mixer enables continuous feeding, mixing, and discharging of granules and liquids, eliminating the need for pauses between batches. It can operate 24 hours a day, with an adjustable hourly mixing capacity of 1-10 tons, directly increasing production capacity by 3-10 times. Its built-in "double-screw feeding + high-speed shear mixing" structure allows granules to fall evenly from the main hopper, while liquid is precisely injected via a metering pump. The paddles in the mixing chamber break up granule agglomerates, allowing the liquid to fully coat the granules, resulting in a mixing uniformity of ≥95%, eliminating product quality issues caused by uneven mixing. The mixing capacity can be set to production requirements (1-50 tons/hour), and there's no limit to the continuous mixing time, making it suitable for both small-scale trial runs and large-scale mass production.

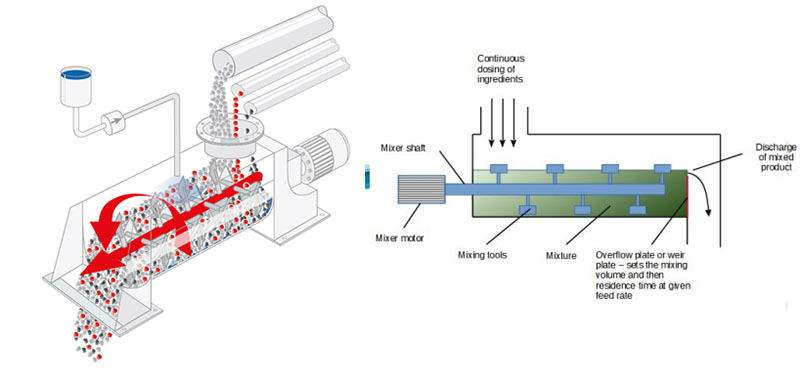

How does a granulules and liquids continuous mixer work?

The operating process of a Granules and liquids continuous mixer is divided into three main steps: feeding, mixing, and discharging.

In the feeding phase, granules are evenly conveyed from the hopper via a variable-frequency twin-screw feeder to prevent granule accumulation and blockage. Liquid is injected into the feed channel at a preset ratio via a high-precision metering pump, ensuring a granule-liquid ratio error of ≤1%.

In the mixing phase, granules and liquid enter a double-layer mixing chamber. The outer, low-speed impellers provide initial mixing, while the inner, high-speed shearing impellers break up granule agglomerates (especially fine particles prone to clumping) while allowing the liquid to fully penetrate the intergranular spaces, achieving "full solid-liquid fusion."

In the continuous discharging phase, the mixed material is stably discharged via an inclined discharging conveyor and directly connected to subsequent production lines (such as granulators and packaging machines). This fully closed-loop operation eliminates downtime and waiting, achieving a truly continuous "feeding - mixing - discharging" process.

Specifications of continuous mixer for granules and liquids

What are the applications of continuous mixers for granules and liquids?

Granules and liquids continuous mixers can be used to continuously mix various types of granular and liquid materials:

Food Industry: flour + water (dough premix), protein powder + nutrient solution (meal replacement powder), milk powder + syrup (toffee raw material);

Chemical Industry: plastic granules + plasticizer (plastic masterbatch), pigment powder + solvent (coatings), rubber granules + silicone oil (rubber products);

Building Materials Industry: cement powder + water + admixture (concrete premix), gypsum powder + glue (gypsum mortar), putty powder + emulsion (wall putty);

Agriculture Industry: fertilizer granules + nutrient solution (slow-release fertilizer), feed granules + oil (high-energy feed), seeds + coating solution (seed coating);

Mining Industry: mineral powder + collector (ore dressing operations), coal slag granules + binder (coal briquette raw material).

How to select a granules and liquids continuous mixer?

Material Characteristics: First, determine the particle size (e.g., 0.1mm or 5mm), whether it tends to agglomerate; the liquid viscosity (e.g., 200mPa・s or 2000mPa・s), and whether it is corrosive. These factors directly determine the equipment material, rotor type, and whether an atomizing nozzle is required.

Mixing Volume Requirement: Select the mixer based on the daily/hourly mixing volume (e.g., if you need 10 tons per hour, choose GL-10; if you need 30 tons per hour, choose GL-30). It is recommended to reserve 10% of the production capacity to avoid insufficient capacity during future expansion.

Customization Requirements: If you have special material requirements (e.g., high temperature resistance, corrosion resistance), or need to adjust the production capacity or dimensions, please contact our online customer service for customized solutions for Granules and liquids continuous mixer, including free trial runs.