What is the purpose of Twin Screw Feeder?

Tuesday July-29 2025 13:53:45

As a mature material conveying equipment, Twin Screw Feeder plays an indispensable role in many industrial fields. Its core function is to stably and continuously convey and measure various bulk materials. Especially when dealing with some materials with special characteristics, it can effectively solve the problems encountered by traditional conveying equipment when dealing with sticky, arched, and non-homogeneous materials, and ensure the stability and continuity of the production process.

What are the uses of Twin Screw Feeder?

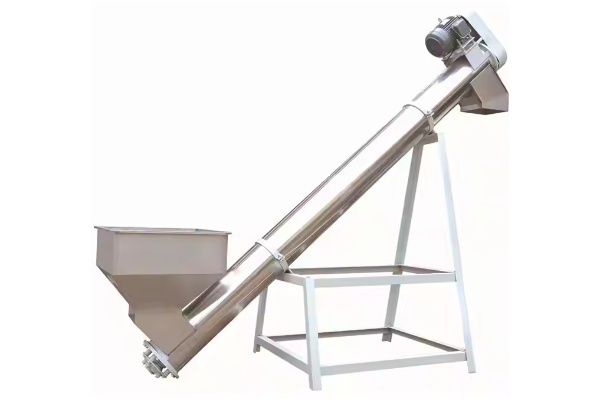

Twin Screw Feeder is a device used to convey and measure bulk materials. It uses two parallel spiral blades to rotate in the shell to push the material from the feed port to the discharge port. This unique design gives it a significant advantage over traditional single screw feeders when handling specific types of materials.

Material Conveying and Metering

The primary purpose of Twin Screw Feeder is to achieve accurate conveying and metering of materials. Compared with the traditional single screw structure, the double screw design uses two mutually meshing or parallel rotating spiral blades to jointly push the material forward. This synergistic effect changes the force state of the material during the conveying process and reduces the possibility of the material slipping or staying in the spiral groove. Therefore, it can provide a more stable material flow, which is crucial for production processes that require precise control of the feed amount.

In terms of metering, Twin Screw Feeder is often used in conjunction with a variable frequency speed control system. By adjusting the speed of the screw, the amount of material delivered per unit time can be changed accordingly. With feedback devices such as weighing sensors or flow meters, closed-loop control can be achieved to maintain the set feeding rate. This ability makes it well suited for ingredient mixing and quantitative dosing, such as mixing different raw materials in proportion in feed production, or accurately adding reactants in chemical production.

Handling difficult-to-flow materials

A significant advantage of Twin Screw Feeder is its ability to handle difficult-to-flow materials. Many bulk materials, such as fly ash, sludge, sawdust, wood chips, paper scraps, flour, starch, bran, and some sticky or easily arched chemical powders, are prone to "bridging" or "adhesion" during traditional single-screw conveying, resulting in poor material flow or even blockage. The design of the double screw can effectively alleviate these problems.

The relative movement of the two screws produces a shearing and stirring effect on the material, which helps to break the "arch" structure formed inside the material and promote the uniform falling of the material. At the same time, the scraping of the spiral blades on the silo wall or the inner wall of the hopper during the rotation process also reduces the adhesion of the material to a certain extent.

Uniform mixing and prevention of segregation

In addition to the conveying function, the Twin Screw Feeder also has a material mixing function to a certain extent. Due to the synergistic effect of the two screws, the material will be repeatedly turned and sheared during the conveying process, which helps to preliminarily mix the materials of different components. Although its mixing effect is not as good as that of professional mixing equipment, this built-in mixing function has certain practical value for application scenarios where the uniformity of the material needs to be maintained during the conveying process.

What are the application fields of Twin Screw Feeder?

As a common device in material handling, Twin Screw Feeder has a wide range of specific applications in multiple industrial fields. Its design characteristics enable it to provide stable conveying and precise metering functions when handling specific types of materials to meet the needs of different production processes. In the food processing industry, Twin Screw Feeder is used to convey and meter various powdered and granular raw materials. For example, in the conveying of dry powders such as flour, starch, powdered sugar, cocoa powder, etc., it can ensure the continuous and stable supply of materials and avoid production interruptions caused by material adhesion or arching. In the production lines of baking, candy, condiments, etc., auxiliary materials such as additives and spices that require precise proportions can also be quantitatively added through Twin Screw Feeder to ensure the stability and consistency of product quality. In addition, for some powders that are easy to absorb moisture or generate static electricity, the closed design of Twin Screw Feeder also helps to maintain the quality of materials. In the feed processing industry, the application of Twin Screw Feeder is particularly common. In the production process of animal feed, aquatic feed and pet food, it is necessary to mix a variety of grains, protein raw materials, vitamins, minerals and additives. These raw materials have different physical properties, some are fluffy, some are sticky, and some require precise proportions. Twin Screw Feeder can effectively handle bran, bran, corn flour, soybean meal and various trace additives. Its forced conveying ability helps solve the bridging and adhesion problems of these materials, ensuring the accurate dosage of each component before mixing. At the same time, the relative movement of the two screws can also perform preliminary mixing of the materials, promoting the uniformity of the subsequent mixing process, which is essential for the production of high-quality, nutritionally balanced feed products.

As a functional conveying device, the core value of Twin Screw Feeder is reflected in its adaptability to specific materials and its stability during conveying and metering. It provides a reliable solution for handling bulk materials that are prone to arching, highly viscous, non-homogeneous or require precise metering. Its application range covers multiple industrial fields and provides basic support for production processes in various industries.