Twin Screw Conveyor Manufacturers

Tuesday December-02 2025 17:32:13

When selecting a Twin Screw Conveyor manufacturer, factors such as conveying distance, conveying capacity, material characteristics, and whether heating, cooling, or mixing functions are required can be considered. For applications requiring simultaneous conveying and mixing, manufacturers with expertise and successful track records in mixing or agitating conveyor models should be chosen.

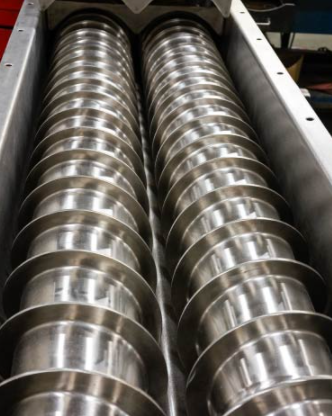

Twin Screw Conveyor Manufacturers offers a variety of models, including single-shaft, twin-shaft, twin-shaftless, and stainless steel types commonly found on the market. Customization services are also available, including adjusting the shape of the spiral blades and selecting special alloy materials. The equipment can be used for both horizontal and inclined conveying, depending on space and material conditions. It operates smoothly and is suitable for the continuous conveying of various materials, including powders, granules, and pastes.

What are the types of Twin Screw Conveyors?

Twin Screw Conveyors can be mainly divided into the following types according to the direction of material conveying:

Horizontal Twin-Helix Conveyor: Material is propelled horizontally by two parallel helical devices. The conveying trough is typically U-shaped or tubular, with two parallel helical shafts installed internally. It is used in applications requiring material to be transported from one point to another at the same height, such as connecting different processing equipment or transferring materials short or long distances on a production line. The structure is relatively simple, installation and maintenance are relatively convenient, and operation is stable.

Inclined Twin-Helix Conveyor: All or part of the conveying section of the conveyor is inclined at a certain angle. To prevent material backflow due to gravity, the design of the helical blades (e.g., pitch, blade shape) may require special adjustments, or a deeper trough design may be used. It is commonly used to lift materials to the top of silos, high-level feed inlets (such as crushers and mixers), or connect production lines at different heights. Compared to vertical conveyors, the inclination angle is more flexible and better adaptable to material characteristics, but the footprint is slightly larger than that of horizontal conveyors.

Twin shaftless screw conveyors: These conveyors use helical blades directly fixed inside the pipe wall, with no central drive shaft. They are suitable for conveying viscous, easily tangled, or easily agglomerated lumpy or pasty materials, such as sludge, municipal solid waste, and pulp. Their key features are strong self-cleaning capabilities and anti-clogging properties. Common screw diameters range from 200-600mm, and conveying lengths typically do not exceed 30 meters. They are suitable for low to medium speed operation, with relatively low throughput but strong anti-clogging capabilities.

Twin shafted screw conveyors: These conveyors are equipped with two solid drive shafts supported by bearings, with helical blades wrapped around them. They are commonly available in carbon steel and stainless steel. Their core function is to achieve fast, stable, and directional material conveying and mixing, making them particularly suitable for processes requiring strict sealing, long distances, or some mixing. Screw diameters range from 100-800mm and above, conveying lengths can reach 70 meters or longer, with a wide range of adjustable speeds and throughput, and higher load-bearing capacity and mechanical strength.

Twin Screw Conveyor Manufacturers can produce all four common types of equipment mentioned above. Each manufacturer has different advantages. Some are simple models, while others have strong processing capabilities. They can add liners inside the housing, on the outer edge of the spiral blades, and in the intermediate suspension bearings to achieve the purposes of wear resistance, anti-sticking, corrosion resistance, noise reduction, and lowering the coefficient of friction.

What are the advantages of Twin Screw Conveyor?

With its unique double-helix design, Twin Screw Conveyor has many advantages in specific application scenarios:

High conveying stability: The two spiral blades work together to form a relatively closed conveying channel, which can push the material more evenly and stably, reduce the fluctuation and slipping of the material during the conveying process, and is particularly suitable for occasions with high requirements for conveying stability.

Strong processing capacity: Compared with the single screw conveyor of the same diameter, the double-helix design provides a larger material cross-sectional area and stronger propulsion force, so in theory and in actual operation, it can usually achieve a higher material conveying volume.

Wide material adaptability: Especially when dealing with some materials with poor fluidity, strong viscosity, easy arching or bridging, the interaction of the double helix can effectively break the arch, loosen the material, avoid blockage, and achieve smoother conveying.

Mixing and stirring effect: During the rotation of the two spiral blades, the material will have a certain shearing, flipping and mixing effect. This allows the Twin Screw Conveyor to play a preliminary mixing or stirring role while conveying the material, which is particularly beneficial for process links that require material uniformity or premixing.

What are the applications of Twin Screw Conveyor?

Twin-screw conveyors can transport materials such as cement, sludge, and municipal solid waste. They can handle materials that are difficult for single-screw conveyors to process. For example, for materials with high viscosity, agglomeration, or entanglement, the twin-screw design can effectively break up arched structures, loosen the material, and prevent blockages. During the conveying process, the coordinated rotation of the two propellers can produce a certain degree of tumbling, shearing, and mixing effect on the material. This makes the twin-screw conveyor not only a conveying tool but also a means of initial mixing or homogenization of materials. Many twin-screw conveyors use covered U-shaped troughs or completely enclosed tubular structures to effectively isolate the material from the external environment during the conveying process, preventing dust spillage, moisture absorption, or contamination.

How to choose Twin Screw Conveyor Manufacturers?

Our factory has been established for 17 years and has many years of experience in R&D and manufacturing. We can design non-standard twin-screw conveyors according to equipment quality, material characteristics, and site conditions. We offer a variety of material options, including stainless steel and carbon steel. Our equipment manufacturing processes meet industry standards, and we provide installation, commissioning, and maintenance services. We are the preferred partner for many industries, including food and logistics.

The key to selecting a Twin Screw Conveyor Manufacturers is whether it can provide equipment that meets actual operating needs. The material characteristics, actual daily or hourly processing volume, required conveying path, on-site space restrictions, and requirements for equipment materials and operating environment should be fully considered. Manufacturers with customization capabilities can adjust the design of the spiral blades, select a suitable drive system, or provide specific anti-wear/anti-corrosion treatments based on this information to ensure stable operation of the equipment.