Food grade ribbon mixer

A food grade ribbon mixer is a key device for mixing ingredients in food processing. Through the circulating convection mixing of a double-layered ribbon within a horizontal drum, it achieves efficient and uniform mixing of food ingredients such as powders and granules. Widely used in baking, seasonings, and snack foods, it is a key piece of equipment for ensuring consistent food quality. Material: 304/316 food-grade stainless steel Speed: 10-60 rpm Specific gravity: Generally suitable for materials with a specific gravity ≤ 5 g/cm³

What is a food grade ribbon mixer?

A food grade ribbon mixer is a horizontal mixing device designed specifically for the food processing industry. Its core feature is its stainless steel construction that meets food hygiene standards. Its food-contact components are easy to clean and have no dead corners, meeting the stringent hygiene and safety requirements of food production. The dual-layered ribbon structure within the horizontal drum (the outer layer pushes the material, the inner layer returns the material) creates a circulating convection flow, achieving efficient and uniform mixing of powders, granules, and slightly viscous food ingredients. It is widely used in the raw material pretreatment stage of food processing.

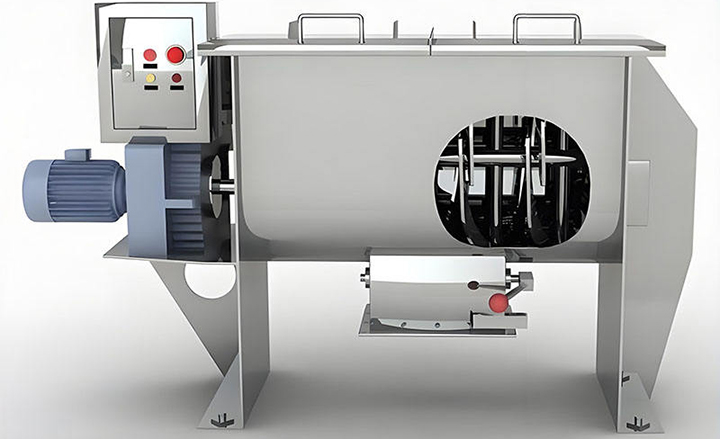

How does a food grade ribbon mixer work?

Food grade ribbon mixer typically utilize a double or multi-layered ribbon structure. The outer ribbon converges the material from the sides toward the center, while the inner ribbon conveys the material from the center to the sides, creating a circular convection flow that results in intense convection mixing within the mixer. The rotation of the ribbon generates strong shear and flow forces, pushing the material through the mixing trough, effectively eliminating dead spots and ensuring uniform mixing of every portion of the material, preventing sedimentation and stratification.

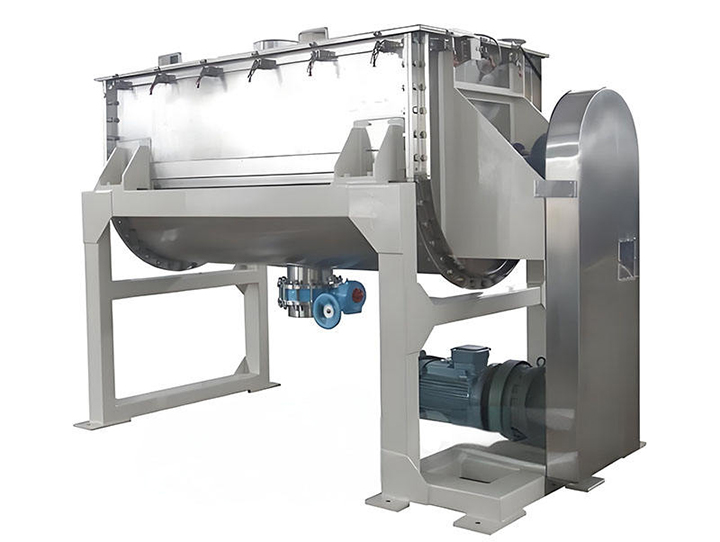

What is the structure of a food grade ribbon mixer?

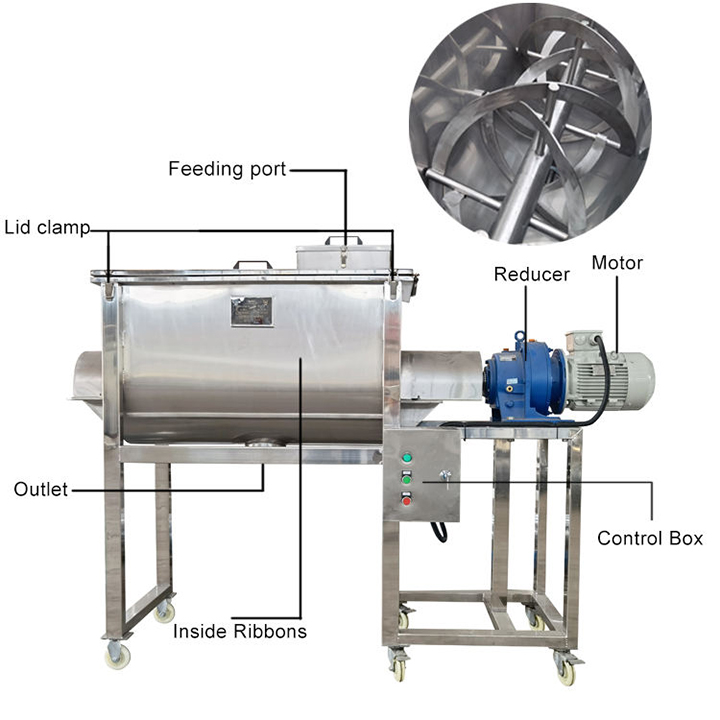

Mixer body: Typically constructed of corrosion-resistant stainless steel (304/316), meeting the hygienic requirements of the food industry.

The ribbon agitator: The core component of the mixer, consisting of two or more layers of inner and outer ribbons. The ribbons rotate in opposite directions, generating propulsion forces in different directions.

Motor and drive system: A high-efficiency motor is used as the power source, with a speed reducer regulating the motor speed. A coupling connects the motor and agitator to ensure stable power transmission.

Feed and Discharge: The feed is located above the drum, conveniently feeding various food ingredients into the mixer. The discharge is typically located at the bottom of the drum and can be equipped with a pneumatically operated wide-opening door or a manual or pneumatic butterfly valve for rapid unloading while preventing cross-contamination.

Control System: Equipped with an advanced PLC control system, parameters such as mixing time and speed can be set to precisely control the mixing process, improving production efficiency and product quality. It also features a fault alarm function to promptly detect and address equipment anomalies.

What are the advantages of food grade ribbon mixer?

Efficient Mixing: Achieves highly uniform mixing in a short period of time, making it particularly suitable for finely blending various powdered and granular food materials.

Hygienic and Safe: Manufactured from food-grade materials, it is easy to clean and effectively prevents material residue and bacterial growth, ensuring food quality and safety.

Versatile: Suitable for a variety of food applications, it can mix materials with different properties, such as powders, granules, and slightly viscous materials. It can also be equipped with a spray system for evenly dispensing liquid seasonings or oils.

Energy-saving and environmentally friendly: Its low-energy design significantly reduces production costs, while operating at low noise levels, meeting environmental requirements.

Intelligent control: Equipped with a PLC automated control system, it achieves efficient production and convenient operation, reducing manual intervention and improving production efficiency.

What are the parameters of a food grade ribbon mixer?

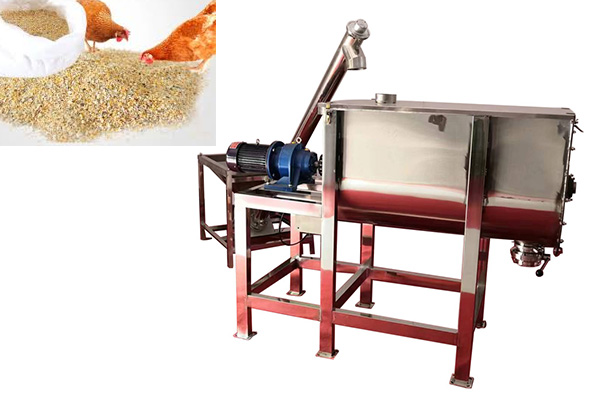

What are the applications of a food grade ribbon mixer?

With its hygienic design, efficient mixing, and flexible adaptability, food-grade horizontal ribbon mixers have become core equipment for ensuring raw material mixing quality and improving production efficiency in food processing. They are a crucial support for food companies to achieve standardized and large-scale production. Compared to conventional equipment or other types of mixing equipment, food-grade horizontal ribbon mixers offer significant advantages in the food industry, including ensuring food hygiene quality, high mixing efficiency, excellent mixing uniformity, strong adaptability, simple operation and maintenance, and stable operation.

Baking and pastry industry: Mixing ingredients such as baking powder, flour, and bread improvers.

Seasoning industry: Mixing various spices and seasonings, and can also be used with a spray system to add oils and liquid seasonings.

Snack Food Industry: Mixed seasonings, dried meat marinade, etc.

Dairy Products and Beverage Industry: Mixed milk powder additives, functional solid beverages, etc.

Health Products and Meal Replacement Industry: Mixed meal replacement powders, nutritional supplements, and other raw materials.