Ribbon Mixer Instant Food Additives

Mix and stir various types of instant food additives, disperse and mix a variety of trace additives with a large amount of basic raw materials (such as milk powder, coffee powder, protein powder, etc.) in a highly uniform manner, make them mix evenly, and improve the taste

Price: $900.00-$7,900.00

Mixing Volume: 100-6000 (kg)

Mixing Time: 8-20min

Voltage: 380V/220V/450V

What are Ribbon Mixers for Instant Food Additives?

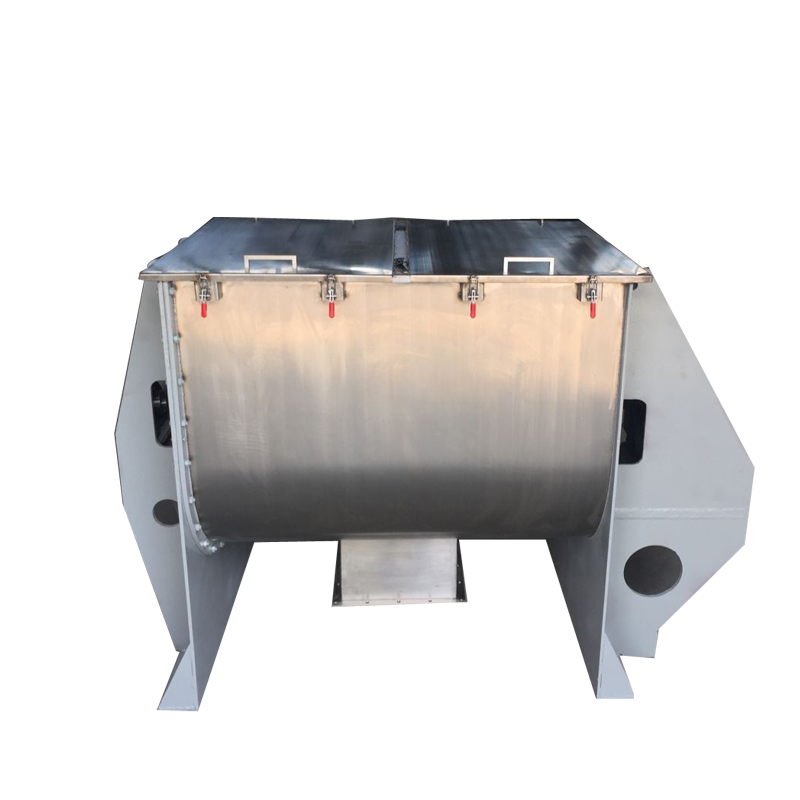

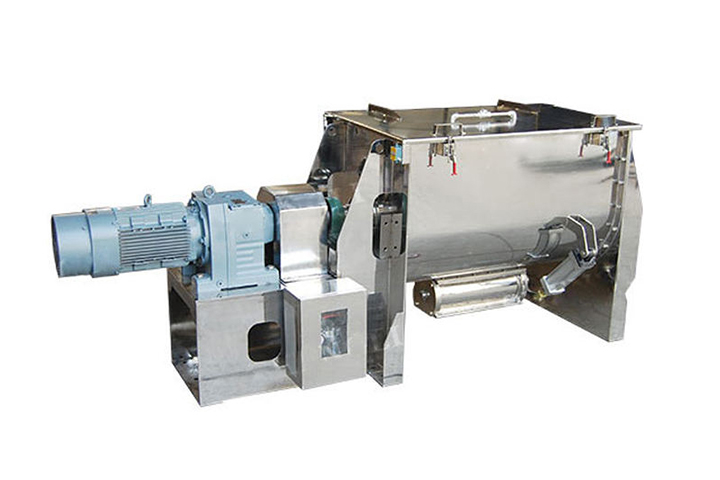

A Ribbon Mixer for Instant Food Additives is a mixing device used in the instant food industry. Featuring a U-shaped container and twin-ribbon impellers, it can mix and agitate various types of instant food additives, ensuring uniform distribution and improving their quality. Mixing time ranges from 5-20 minutes, and it can mix up to 6,000 kg at a time. Larger models are also available upon request.

The Ribbon Mixer for Instant Food Additives can be used to process a variety of instant food additives, including powders, granules, and solids such as instant tea powder, milk powder, coffee creamer, and condiments. It is particularly suitable for processing instant food additives containing trace ingredients. Even at a mixing ratio as low as 1:10,000, it ensures uniform distribution of ingredients, ensuring consistency and stability in each batch.

What are the types of Ribbon Mixers for Instant Food Additives?

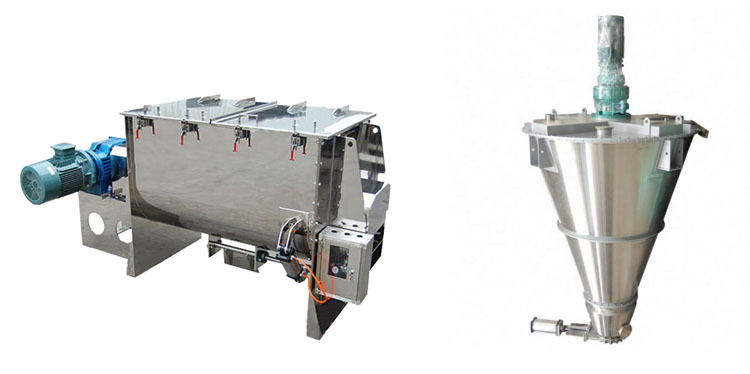

Ribbon mixers for instant food additives are primarily available in two types: horizontal and vertical. Each type is designed to mix different instant food additives and has different application scenarios:

Horizontal Ribbon Mixers for Instant Food Additives: The horizontal structure allows for thorough tumbling of materials during mixing, and the combination of internal and external ribbons achieves efficient convection mixing. These mixers are commonly used for large quantities of instant food additives requiring high mixing uniformity, such as mixing various flavorings in instant coffee powder, creamer, sugar, and flavorings in instant milk tea powder, and have capacities up to 10,000 liters.

Vertical Ribbon Mixers for Instant Food Additives: Its compact footprint makes it suitable for production environments with limited space. When mixing lightweight, fluid instant food additives, such as powdered seasonings in instant soups, vertical ribbon mixers, with their unique agitation method, achieve rapid and uniform mixing. Capacities range from 400 to 12,000 kg.

What are the advantages of Ribbon Mixer for Instant Food Additives?

The Ribbon Mixer Instant Food Additives achieves high mixing uniformity, achieving a mixing ratio of 1:10,000. It is particularly suitable for materials with large specific gravity differences. It also boasts a fast mixing speed, achieving thorough mixing in just 1-10 minutes per batch, a 6-10 times improvement in efficiency compared to conventional equipment. The loading factor exceeds 70%, enabling high throughput. The equipment is easy to clean, allowing for quick and thorough cleaning between shifts, leaving no dead corners. Discharge is rapid, completing the process in 1-2 minutes, with minimal residual material. The mixing process is gentle, leaving little physical damage to the material, making it particularly effective for preserving the solubility characteristics of instant food additives.

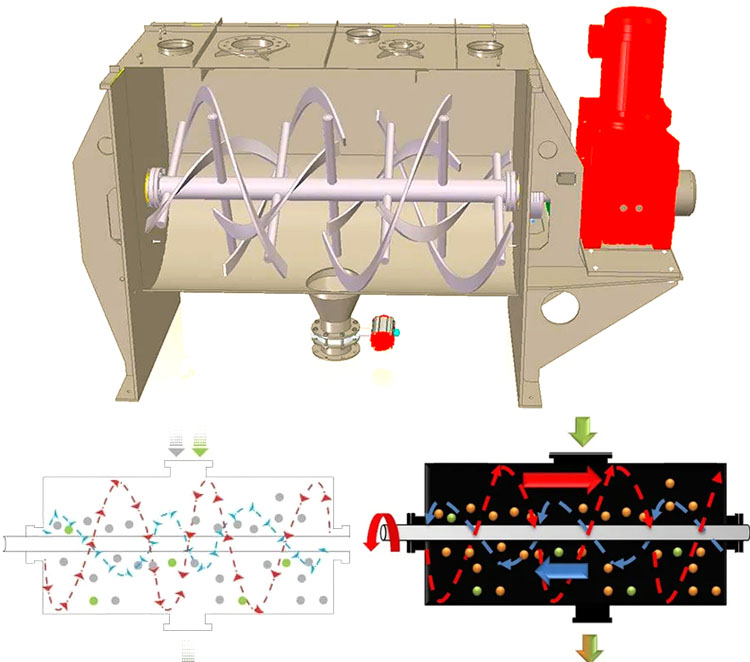

How does the Ribbon Mixer Instant Food Additives work?

The Ribbon Mixer Instant Food Additives utilizes the rotation of the spiral ribbon to propel the instant food additives. As the ribbon rotates, the inner ribbon pushes the instant food additives from the center toward the ends, while the outer ribbon draws the additives toward the center. This counter-movement creates a strong convective mixing effect. At the same time, the ribbons create axial and radial motion, further promoting interpenetration and diffusion between the additives, resulting in rapid and uniform mixing.

Ribbon Mixer Instant Food Additives Specifications

| Model | Effective Volume (m²) | Batch Output (kg) | Spindle Speed (rpm) | Drive Power (kW) | Equipment Weight (kg) |

| WLDH-500 / HDL500 | 0.3 | 200-300 | 60 | 4-11 | 900 |

| WLDH-1000 / HDL1000 | 0.6 | 400-600 | 42 | 7.5-15 | 1800 |

| WLDH-1500 / HDL1500 | 0.9 | 600-900 | 32 | 11-18.5 | 2500 |

| WLDH-2000 / HDL2000 | 1.2 | 800-1200 | 32 | 15-22 | 3200 |

| WLDH-3000 | 1.8 | 1200-1800 | 30 | 18.5-30 | 3300 |

| WLDH-4000 / HDL4000 | 2.4 | 1600-2400 | 30 | 22-37 | 5100 |

| WLDH-6000 / HDL6000 | 3.6 | 2400-3600 | 28 | 37-55 | 6300 |

| WLDH-8000 / HDL8000 | 4.8 | 3200-4800 | 28 | 37-55 | 7500 |

What are the applications of the Ribbon Mixer Instant Food Additives?

The Ribbon Mixer Instant Food Additives uniformly mixes various instant food additives. It is suitable for mixing ingredients in solid powder, granular, and fine powder forms, including instant coffee, milk powder, soy powder, fruit extract, tea powder, protein powder, cereal ingredients, seasoning powder, enzyme preparations, nutritional supplements, and functional additives for soups and sauces. This equipment efficiently handles formulations with high proportion variances and is particularly suitable for materials requiring high solubility and uniformity. It ensures rapid dissolution without clumping, while preserving the additive's original physical properties and flavor.

| Application Scenario | Mixed Material Example | Estimated Mixing Time | Estimated Mixing Volume (Per Batch) |

| Instant Beverage Powder Production | Instant tea powder, powdered sugar, acidulants (e.g., citric acid), flavors and spices, etc. | 1-10 minutes | Capacity over 1000kg |

| Nutritional fortified milk powder ingredients | Milk powder base, vitamin mix, mineral additives, probiotic powder | 1-10 minutes | Capacity over 1000kg |

| Seasoning powder and soup base | Salt, MSG, pepper, dehydrated vegetable granules, yeast extract, spice powder | 1-10 minutes | Capacity over 1000kg |

| Food Additive Premix | High-rate dilution and mixing of various trace food additives (such as preservatives, colorants, and antioxidants) with carriers (such as starch and dextrin) | 1-10 minutes | Capacity can reach over 1000 kg |