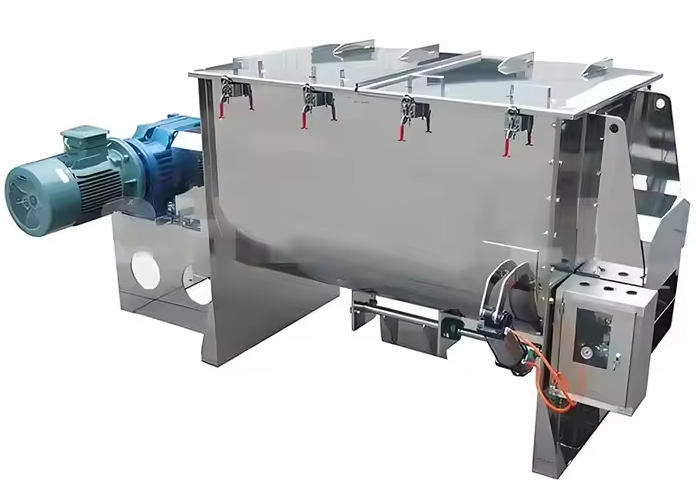

Coffee Powder Mixer

Coffee powder mixers are primarily used to ensure flavor consistency and ingredient stability in coffee products Contact Materials: 304 Stainless Steel 316 optional Speed: Typically 10-60 rpm Support Steel: 304 or 316 Stainless Steel Mixing Time: 5-20 minutes

What is a coffee grounds mixer?

A coffee powder mixer is a type of material mixing equipment specifically designed for coffee production, processing, or blending. It uses mechanical agitation to uniformly blend coffee powders of varying characteristics or various additives. This ensures a consistent flavor and stable composition in the resulting blended coffee, improving coffee quality.

How a Coffee Powder Mixer Works

The coffee powder (or coffee powder and additives) to be mixed is placed into the mixer's drum in the desired proportions. The mixer's agitator then performs a series of mixing operations, including convection mixing, shear mixing, and diffusion mixing. The continuous agitation of the agitator gradually achieves a uniform blend. The material is then discharged, providing a fully mixed supply for subsequent production operations. It is widely used in coffee processing plants, food companies, and small coffee studios for both batch production and small-batch customization.

Precautions for Coffee Powder Mixing

During the coffee powder mixing process, coffee powder is lightweight and highly fluid. Furthermore, particle size can affect coffee flavor, so particle disruption must be minimized. The aroma of coffee grounds is primarily due to volatile components such as esters and aldehydes. These substances oxidize over time in contact with air, causing the coffee flavor to fade and affecting the quality.

Easy to fly: Light coffee grounds are prone to dusting during mixing, so mixing equipment should be well sealed.

Easy to break: Mixer parameters must be precisely controlled to avoid excessive stirring, which can lead to uneven mixing, while also avoiding excessive stirring, which can damage the coffee grounds' particle size and affect the flavor and quality.

Easy to oxidize: The aromatic components of coffee grounds oxidize in air, and stirring further accelerates this oxidation rate (as the material comes into more contact with air). Therefore, the stirring time should be appropriately controlled. In some cases, vacuum mixing or the use of inert gas may be necessary to preserve the flavor of the coffee grounds.

Basic Parameters of Coffee Powder Mixers

Capacity: Small equipment used in workshops or laboratories typically has an effective volume of 50-500L; medium-sized equipment typically has a capacity of 500-2000L; and large equipment can reach over 2000L.

Power: The power of a coffee mixer is related to its capacity, ranging from 1.5-5.5kW for small machines, 5.5-15kW for medium machines, and 15-30kW for large machines.

Speed: Typically 10-60 rpm.

Mixing Time: 5-20 minutes.

Material: Parts that come into contact with the product are made of food-grade stainless steel.

Choosing a Coffee Mixer

Horizontal Mixer: Suitable for medium to large-scale production. It offers high mixing uniformity and is ideal for mixing powders and granules.

Vertical Mixer: Suitable for small batches or labs.

Vacuum Mixer: Mixes under vacuum, ensuring a richer flavor.

Material Capacity: Select a motor with the appropriate capacity and power based on the amount of coffee powder to be mixed.

Applications of Coffee Powder Mixers

Coffee powder mixers are primarily used to ensure flavor consistency and ingredient stability in coffee products:

Precisely blending coffee powders of different varieties, origins, and roasts balances flavor characteristics such as acidity, bitterness, and aroma, ensuring a consistent taste across batches and avoiding flavor fluctuations due to raw material differences.

In the production of instant coffee and flavored coffee, coffee powder is thoroughly mixed with non-dairy creamer, powdered sugar, flavorings, and functional additives to prevent uneven flavor due to localized concentrations of ingredients, thereby ensuring a uniform taste and nutritional profile.

Related news

- Tablet and powder packaging machine

- Fully Automatic Small Bag Powder Packaging Machine

- Silica powder packaging machine

- Automatic Chemical Powder Filling Packing Machine

- What is a double-shaft screw conveyor?

- Horizontal ribbon mixer manufacturer

- Stainless steel animal feed horizontal ribbon mixer for feed additives

- 1000L stainless steel ribbon mixer for milk powder raw materials