Stainless steel animal feed horizontal ribbon mixer

The material is mixed by the rotation of the spiral ribbon. It is often used to mix various feed raw materials, such as powdered, granular materials and trace additives, to meet the nutritional needs of animals at different growth stages

Energy saving\high efficiency\short time

Mixing time: 3-10 minutes

One-time mixing: 100-5000 (kg)

Capacity: 200L-50,000L

Voltage: 220V/380V, 50Hz/customized

Material: 304L stainless steel\316L stainless steel

Power: 2.2-110kw

Application: feed, food and other industries with strict hygiene requirements

Promise: Free shipping/5 days delivery/30 days return and exchange/support customization

Product Overview

This design can overcome the differences in the physical properties of the various components of the feed, effectively avoid dead corners of mixing, and achieve a highly uniform mixing effect in a relatively short time. The mixing uniformity can reach more than 95%. Whether it is complete feed for livestock and poultry, aquatic feed, or a fine formula containing trace additives, it can be fully mixed to ensure balanced feed nutrition and healthy growth of animals. It is a key equipment for large-scale feed processing plants to ensure product quality.

What can the stainless steel animal feed horizontal horizontal ribbon mixer be used for?

The stainless steel animal feed horizontal horizontal ribbon mixer plays a core role in modern feed production, and its application scenarios are extremely wide and specific. It is mainly used for large-scale or high-precision compound feed production, such as in large feed mills, for mixing bulk raw materials such as corn, soybean meal, bran, fish meal, and trace additives such as vitamins, minerals, and amino acids to ensure that the final pig feed, chicken feed, cattle and sheep feed, etc. are balanced and meet the nutritional needs of animals at different growth stages.

In addition, it is also crucial in the production of premixes and concentrates, because these products usually contain highly active or trace ingredients and require extremely high mixing uniformity. For example, when producing veterinary premixes, functional additives or special aquatic feeds, its efficient ribbon structure can ensure that trace ingredients are evenly dispersed in the overall material, avoiding local excess or deficiency of drugs or nutrients, thereby improving feed effects and animal health. Its stainless steel material ensures that there will be no contamination of the feed during the mixing process.

The difference between stainless steel animal feed horizontal ribbon mixer and vertical mixer

Stainless steel feed mixers are crucial in feed production. They can ensure that various raw materials are fully mixed to meet the formulation requirements. Among them, horizontal ribbon mixers and vertical mixers are two common types. They have significant differences in structure, working principle, scope of application and performance.

| Features | Horizontal ribbon mixer | Vertical mixer |

| Picture |

|

|

| Structure | U-shaped cylinder, double-layer ribbon stirring blades, horizontal design | Conical or cylindrical cylinder, vertical spiral or paddle stirring |

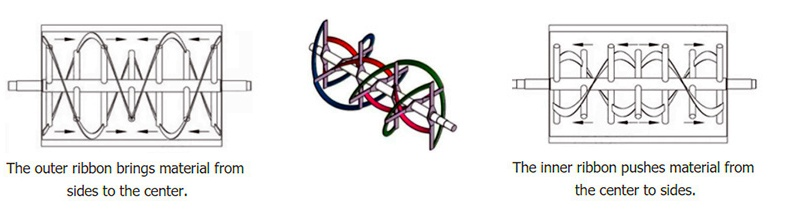

| Mixing principle | The outer ribbon is pushed to the center, and the inner ribbon is pushed to the sides to form convection mixing | The material is lifted from the bottom to the top by the spiral, and then falls back by gravity for cyclic mixing |

| Mixing uniformity | High (CV≤5%), suitable for uniform mixing of various materials | Slightly lower (CV≤7-10%), the mixing effect is weak for materials with poor fluidity |

| Mixing time | Short (3-5 minutes/batch), high efficiency | Long (5-10 minutes/batch), efficient Low rate |

| Applicable materials | powder, granules, liquids, viscous materials, strong adaptability | mainly used for powders and granules, liquid or viscous materials have poor mixing effect |

| Loading coefficient | higher (40%-70%), high capacity utilization | lower (30%-50%), low capacity utilization |

| Application scenarios | large feed mills, food processing, chemical industry, suitable for high output and diversified materials | small and medium-sized farms, simple feed formula processing, suitable for single or small amounts of materials |

Horizontal ribbon mixers perform better in mixing uniformity, mixing efficiency and material residue, and are especially suitable for feed production lines with high requirements for mixing quality. Vertical mixers, with their simple structure, small footprint and low cost, are suitable for occasions with small output and less stringent requirements for mixing uniformity.

How does the stainless steel horizontal ribbon mixer for feed work?

The stainless steel horizontal ribbon mixer for feed is a high-efficiency mixing equipment with a U-shaped barrel and a built-in bidirectional ribbon stirring structure.

When the equipment is running, the motor drives the ribbon stirring shaft to rotate, and the spiral ribbon drives the material in the barrel to flow in both axial and radial directions. Double-layer spiral blades are arranged on the transmission main shaft. The inner spiral conveys the material to the outside, and the outer spiral gathers the material to the inside. Under the convection movement of the double-layer spiral belt, a low-power and high-efficiency mixing environment is formed.

When the agitator is working, the inner spiral drives the material near the axis to rotate axially, and the axial direction is pushed from the inside to the sides. The outer spiral drives the material near the barrel wall to rotate axially, and the axial direction is pushed from the sides to the inside, so that the material convects and circulates in the barrel, shears and permeates, and achieves uniform mixing in a short time.

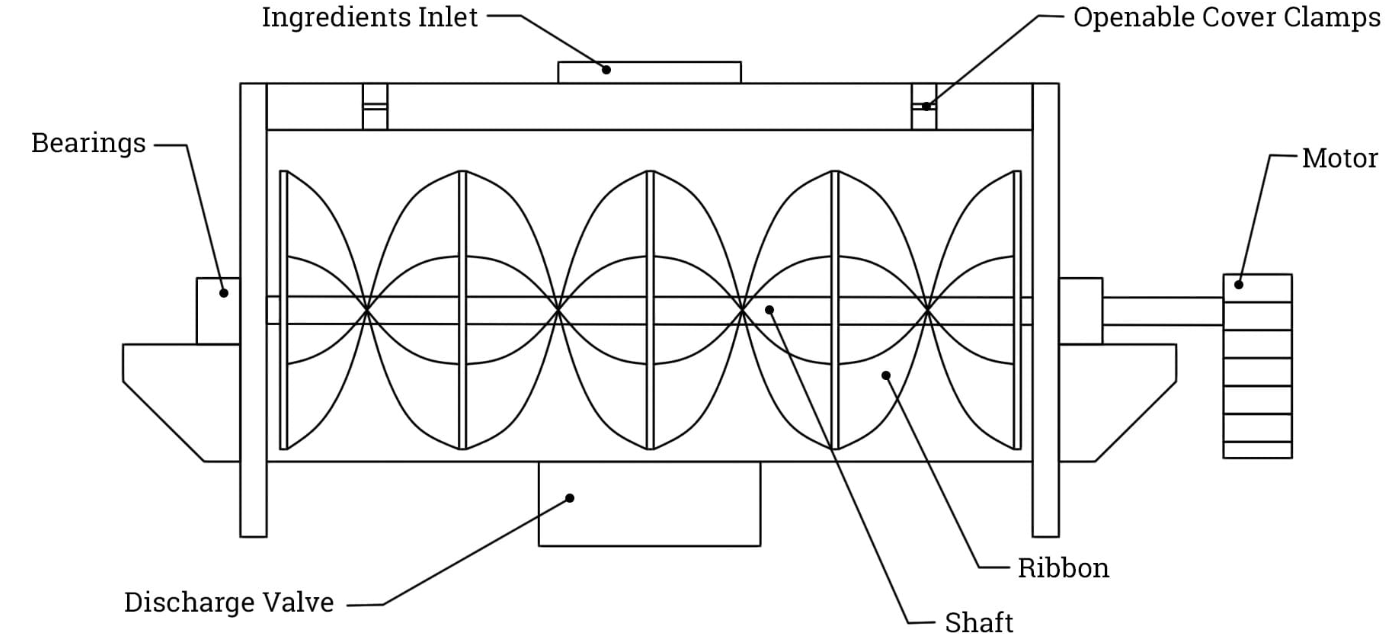

Main structural composition of stainless steel animal feed horizontal horizontal ribbon mixer

Stainless steel animal feed horizontal ribbon mixer generally consists of the following main parts:

U-shaped barrel: The barrel is usually a long U shape. This structural design allows the material to flow freely in the barrel, reducing the accumulation and dead corners of the material, and ensuring that there is no dead corner in the mixing.

Double-layer spiral ribbon configuration: The inner and outer spiral ribbons rotate in opposite directions, covering the entire barrel range, and the mixing efficiency is increased by more than 30% compared with the single-layer structure.

Discharging method: Powder materials generally adopt pneumatic large-opening door structure, which has the advantages of fast unloading and no residue; high-fineness materials or semi-fluid materials use manual butterfly valves or pneumatic butterfly valves. Manual butterfly valves are economical and applicable, and pneumatic butterfly valves have good sealing properties for semi-fluids, but the cost is higher than manual butterfly valves.

Transmission system: It consists of a motor, a reducer and a transmission shaft, usually installed on one side of the barrel to drive the stirring shaft to rotate.

Bracket and frame: The supporting structure of the whole machine, usually made of carbon steel or stainless steel.

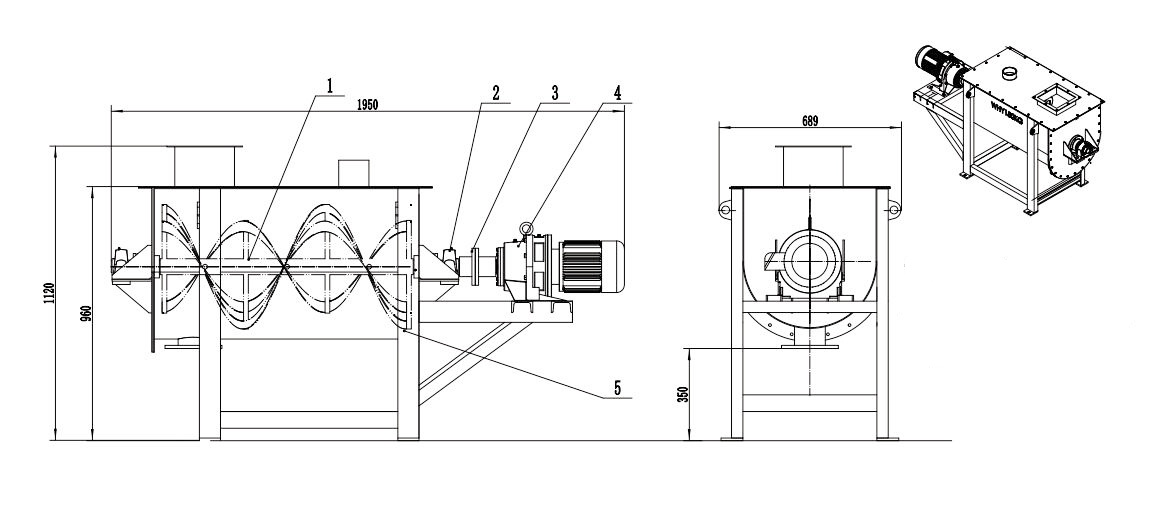

Technical parameters of stainless steel animal feed horizontal ribbon mixer

| Model | Power(KW) | Capacity(L/Volume) | Max Mixing Powder Weight(kg/batch ) | Mixing time(mins/batch) | SizeL*W*H (cm) |

| THMR100 | 3 | 280 | 100 | 6--8 | 180*70*150 |

| THMR300 | 4 | 480 | 300 | 6--8 | 240*80*190 |

| THMR500 | 5.5 | 700 | 500 | 8--10 | 270*90*200 |

| THMR1000 | 7.5 | 1500 | 1000 | 8--10 | 310*110*200 |

| THMR1500 | 11 | 2100 | 1500 | 8--12 | 310*110*200 |

| THMR2000 | 15 | 3200 | 2000 | 8--12 | 350*130*240 |

| THMR3000 | 18.5 | 4300 | 3000 | 10--16 | 375*135*240 |

| THMR5000 | 22 | 6400 | 5000 | 10--16 | 390*165*270 |

Scope of application

This equipment is suitable for mixing the following types of materials:

Feed raw materials: such as soybean meal, corn meal, bran, fish meal, premixes, etc.; chemical powders: such as additives, additives, particle compounds, etc.;

Food powders: such as flour, seasonings, additives, etc.; building materials industry: such as dry mortar, putty powder, etc.

For the feed processing industry, this equipment is particularly suitable for mixing premixes and trace additives of different proportions, which can effectively ensure the uniformity and stability of the formula.

What are the advantages of stainless steel horizontal ribbon mixer for feed?

High mixing uniformity: When the ribbon structure is reasonably designed, it can achieve very high mixing uniformity (low coefficient of variation CV value), ensuring the accuracy of feed nutritional formula, which is especially important for premixes and core materials.

High mixing efficiency: The mixing cycle is relatively short and the processing volume is large per unit time.

Low residue: Well-designed ribbons and smooth stainless steel inner walls, combined with large door unloading, can greatly reduce cross-contamination between batches and ensure feed quality and safety. The residue rate can usually be controlled at 0.1% or even lower.

Wide range of application: It can effectively mix powder, granular materials, and materials with appropriate amount of liquid (such as oil, molasses, water). It has a certain tolerance for differences in density and particle size of materials.

Stainless steel horizontal ribbon mixer for feed manufacturer

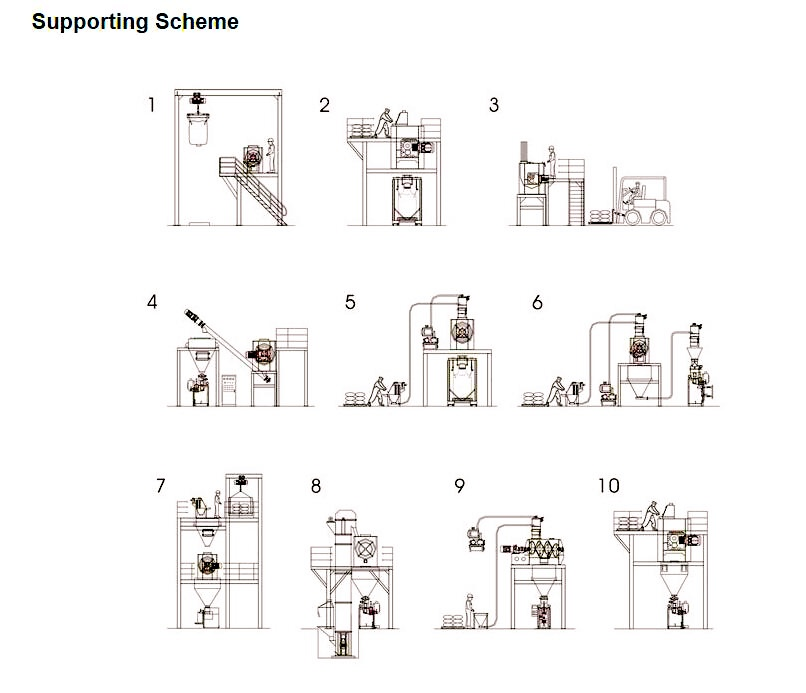

Professional feed ribbon mixer is a feed processing equipment, which is widely evaluated in high-efficiency animal husbandry, pet food, aquaculture, food, chemical and other industries, and is used to evenly mix powder, granular, liquid or horizontal thickening ingredients. As a professional manufacturer, Dahan Machinery provides a variety of feed horizontal ribbon mixers with the following features:

Material: 304 or 316L stainless steel, corrosion-resistant, easy to clean, in line with food-grade hygiene standards, suitable for processing high-humidity or corrupt feed raw materials

High-efficiency spiral ribbon design, the outer spiral ribbon pushes the feed to the center, and the inner belt pushes to the minimum value, forming convection mixing, 3-20 minutes to complete 100-6000kg mixed feed, uniformity up to CV≤3%, no stratification

Customization: Capacity range 100-5000L, support vacuum, explosion-proof and other configurations

Supporting equipment: can be combined with screw conveyors, dischargers, etc. to form an automated production line to improve production efficiency

If you need to know more about Dahan Machinery's models, quotations or customization needs, please contact customer service directly.