Animal Feed Granule Packaging Machine

Animal Feed Granule Packaging Machine typical packaging range is 20-50 kg/bag, but custom sizes of 1-10 kg small bags or ton-sized bags are also available. The speed reaches 480-700 bags/hour. Prices vary depending on configuration, ranging from approximately US$1,200 to US$3,000 for a basic model, to approximately US$8,000 for a fully automatic, high-speed model (including weighing and bag sewing). Packaging Range: 5-50 kg/bag Power: 1.1-5 kW Accuracy: ±0.1%-0.2% Speed: 5-700 bags/hour

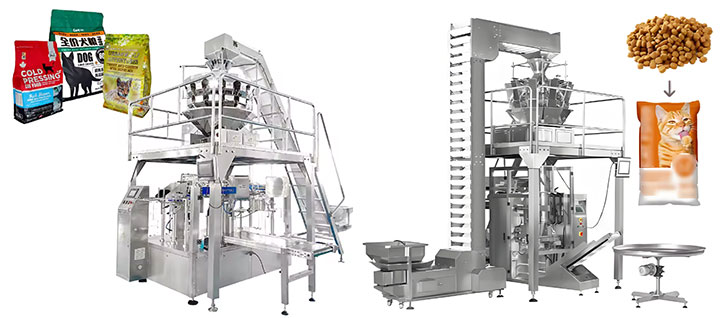

What is an Animal Feed Granule Packaging Machine?

Animal Feed Granule Packaging Machine is an automated packaging machine designed for livestock feed and pet food. It accepts pre-made bags, such as woven or paper bags, or stand-up pouches, using heat-sealing, ultrasonic sealing, or crimping to ensure a moisture-proof seal. Typical sizes range from 20-50 kg per bag, but custom sizes, such as 1-10 kg small bags or jumbo bags, are also available. Speeds can reach 480-700 bags per hour. Prices vary depending on configuration, ranging from approximately US$1,200 to US$3,000 for basic models and around US$8,000 for fully automatic, high-speed models.

The Animal Feed Granule Packaging Machine completes feed packaging through an automated process: feed pellets are conveyed to a storage hopper and weighed in real time by a high-precision sensor. The filling process is divided into two stages: fast and slow, ensuring precise weight accuracy of ≤0.2%. After filling, a pneumatic system automatically clamps and seals the bag with heat or crimping, while a conveyor belt removes the completed bag.

Animal Feed Granule Packaging Machine Features

The Animal Feed Granule Packaging Machine automatically weighs, fills, handles, and conveys bags. It also features intelligent control functions including alarms, data logging, and optional label printing.

Automatic Weighing: Utilizing a load cell or volumetric metering system, the machine achieves high-precision weighing, ensuring accurate weight with an error within ±0.2%. Some models also feature multi-stage weighing hoppers, such as a dual-hopper design, which effectively increases packaging speed.

Bagging and Filling: Bagging can be performed using gravity or pneumatic filling for pellet feeds of varying particle sizes (typically 2-10mm). The equipment's dust-proof design effectively reduces dust emissions and maintains a clean production environment.

Bag Handling: Some high-end models support fully automatic bag removal and opening (requiring pre-made bags or roll film), enabling automated bagging and retrieval. Sealing can be configured with either seam or heat sealing devices, adapting to sealing requirements for various bag materials, such as woven bags and PE bags.

Conveying and Sorting: After packaging, finished products are automatically transported to palletizing or storage areas via belt or chain conveyors. The equipment also features a shaping and flattening function to ensure uniform bag shapes for subsequent stacking and transportation.

Intelligent Control: Utilizing a combination of PLC and touchscreen control, users can set parameters such as weight and bag count via the touchscreen, store recipes, and generate prompt alarms in the event of a malfunction. Furthermore, the equipment features data logging, production statistics, and optional label printing.

Animal Feed Granule Packaging Machine Technical Specifications

VFS5000/7300 A5 Automatic Stable Four-Pouch Forming and Packaging Machine.

|

Model |

External dimensions (L×W×H) mm |

Type of bag |

Range of bag width (L×W) mm |

Packaging speed bags/min |

ID of reel |

Max. allowable OD of reel |

Compressed air requirement |

Power supply |

|

VFS5000A5 |

2455×1230×1660 |

Quad bag, bag with hole punching |

1、Front face width: 50~190 2、Side face width: 50~90 3、Width of corner seal:5~8 4、Bag length range: 100-350mm 5、Max.width of packaging material: 520mm |

15~55 |

Ф75mm |

Ф450mm |

0.6MPa 350 L/min |

380V 50~60Hz 3kW |

|

VFS7300A5 |

2550×1420×1930 |

1、Front face width: 60~260 2、Side face width: 60~120 3、Width of corner seal: 5~10 4、Bag length range: 100-460mm 5、Max.width of packaging material: 730mm

|

2~45 |

Ф75 mm |

Ф450 mm |

0.6MPa 0.36L/min |

380V 50~60Hz 3kW |

Vertical Packaging Unit - Classic Single Unit

VFS320/5000D/5000B/7300B/9000/1100/1500/1700 Vertical Form Filling and Packaging Machine.

|

Model |

External dimensions (L×W×H) mm |

Type of bag |

Range of bag width (L×W) mm |

Packaging speed bags/min |

ID of reel |

Max. allowable OD of reel |

Compressed air requirement |

Power supply |

|

VFS320 |

1050×800×1010 |

Pillow bag, gusset bag, die cut bag |

(80~200)×(80~150) |

40~80 |

Ф72mm |

Ф400mm |

0.6MPa 350 L/min |

380V 50~60Hz 3kW |

|

VFS5000D |

1470×988×1400 |

(80~280)×(80~200) |

30~80 |

Ф75 mm |

Ф400 mm |

0.6MPa 0.36L/min |

380V 50~60Hz 3kW |

|

|

VFS5000B |

1800×1220×1680 |

(100~350)×(100~250) |

20~90 |

Φ75mm |

Φ450mm |

0.6MPa 350L/min |

380V 50~60Hz 5.5kW |

|

|

VFS7300B |

1854×1440×1930 |

(100~460)×(100~350) |

30~80 |

Φ75mm |

Φ500mm |

0.6MPa 350L/min |

380V 50~60Hz 6kW |

|

|

VFS9000 |

1900×1470×2080 |

(300-650)×(300-450) |

20~60 |

Φ75mm |

φ450mm |

0.6~0.8MPa 350 L/min |

380V 50~60Hz 6kW |

|

|

VFS1100 |

2150×1750×2300 |

(300-650)×(300-550) |

5-30 |

Φ75mm |

Φ600mm |

0.6~0.8MPa 300 L/min |

380V 50~60Hz 6.5kW |

|

|

VFS1500 |

2210×2191×2572 |

(300~1000)×(350~750) |

5~15 |

Φ75mm |

Φ600mm |

0.6MPa 360 L/min |

380V±10% 50Hz 8KW |

|

|

VFS1700 |

6000×6000×9345 |

(300~1000)×(500~850) |

2~5 |

Φ75mm |

Φ600mm |

0.8MPa 360 L/min |

380V ±10% 50Hz 11KW |

Animal Feed Granule Packaging Machine Types

Animal feed granule packaging machines are generally categorized into three types: fully automatic and fully unmanned, suitable for large-scale plants; semi-automatic and manual-assisted, suitable for small and medium-sized plants; and high-speed, high-precision, multi-head combination weighing machines suitable for large-scale production.

Fully automatic packaging machines integrate automatic weighing, filling, sealing, conveying, and palletizing functions, achieving fully unmanned operation. They are suitable for large feed plants or high-capacity production scenarios, such as production lines with an hourly packaging capacity exceeding 600 bags (25 kg/bag). Their advantages include significantly improving production efficiency, reducing labor costs, and ensuring consistent packaging specifications. For example, a fully automatic packaging line combined with a robotic palletizing system can achieve a high efficiency packaging capacity of thousands of bags per hour.

Semi-automatic packaging machines require manual assistance for some steps, such as bagging and sealing, but the core weighing and filling processes are automated. They are primarily designed for small and medium-sized feed plants or those with lower production capacity requirements. Their advantages include lower equipment costs and high operational flexibility, making them particularly suitable for businesses with limited budgets or fluctuating production capacity, as they can flexibly adjust production schedules through manual intervention.

Multi-head combination weighing scale packaging machines utilize multiple weighing units, working in tandem to achieve high-speed, high-precision packaging. They are particularly suitable for large-scale production scenarios with packaging volumes exceeding 1,000 bags per hour. Their core advantages include weighing accuracy of up to ±0.2% and packaging speeds over 30% higher than traditional equipment, effectively meeting the demands of high-efficiency and high-stability production.

Animal Feed Granule Packaging Machine Price

Animal Feed Granule Packaging Machine prices vary: small stand-alone machines range from $2,400 to $4,000; heat-sealing packaging scales range from $3,500 to $6,000; semi-automatic large-scale packaging systems range from $5,500 to $7,000; and high-end multi-head pre-made bagging equipment costs approximately $9,000.

Small standalone packaging machines are compact, have a packaging capacity of 5-50 kg, and are priced between $2,400 and $4,000. They are suitable for small production lines or small- to medium-sized industries. They feature basic weighing and bagging functions, are easy to operate, and have low maintenance costs. They are suitable for daily production of 5-20 tons of animal feed pellets, and are ideal for the daily packaging needs of farms, feed mills, and other applications.

Heat-sealing packaging scales, based on small packaging machines, add heat-sealing capabilities. They have a capacity of 5-50 kg and are priced between $3,500 and $6,000. They accurately weigh and automatically heat-seal to prevent moisture from entering the feed, improving product appearance and storage stability. They are suitable for daily production of 8-25 tons and are particularly suited to feed companies with high demands for finished product quality.

Semi-automatic large-scale packaging systems, priced between $5,500 and $7,000, offer comprehensive functionality and a capacity of 15-50 kg. These systems include automatic weighing, filling, conveying, and sealing modules, improving efficiency and reducing labor. Suitable for daily production of 30-80 tons, they are ideal for large-scale feed mills and fertilizer plants, among others, that handle large volumes of feed.

High-end multi-head pre-made bag systems, priced around $9,000, are high-speed, precision equipment that includes a multi-head metering system and can handle multiple packaging lines simultaneously, ensuring high efficiency and accuracy. Suitable for daily production of 100-200 tons, they are ideal for large feed mills, export companies, and other environments with high production capacity and quality requirements.

Animal Feed Granule Packaging Machine Solution

When choosing an Animal Feed Granule Packaging Machine, you need to precisely match the model to the packaging capacity. Small capacities of 200g-5kg are suitable for small vertical packaging machines, which take up little space, offer high sealing accuracy, and are ideal for small-portion packaging needs such as pet feed. These machines can automatically measure and form bags. Medium capacities of 10-25kg are preferably medium-sized horizontal packaging machines, equipped with spiral or belt feed mechanisms, offering both speed and metering stability, suitable for conventional poultry feed packaging. Large capacities of 50-100kg require heavy-duty fully automatic packaging machines equipped with a large-diameter feed inlet and adaptability for ton bags or woven bags. These machines integrate automatic weighing, sealing, and conveying functions to meet the needs of large-scale feed factories for bulk packaging.

Applicable Materials for the Animal Feed Granule Packaging Machine

The Animal Feed Granule Packaging Machine is suitable for quantitative packaging of various animal feed pellets. It is suitable for a wide range of materials, including livestock pellets for poultry such as chickens, ducks, and geese, as well as livestock such as pigs, cattle, and sheep; aquaculture pellets for fish, shrimp, and crab; pet food pellets such as cat and dog food; and pet feed pellets for birds and rodents; specialty feeds such as laboratory animal feed and insect feed such as mealworms and crickets; as well as granular feed ingredients such as extruded corn and soybean meal pellets.